Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Ene . 20, 2025 04:30

Back to list

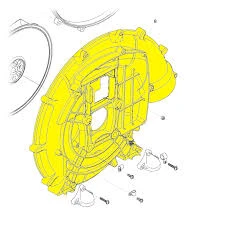

Connector bracket

When exploring the vast world of fluid dynamics and mixing technologies, the anchor impeller stands as a fundamental component of critical processes across diverse industries. Understanding its functionalities and applications not only underscores its indispensable role but also unveils opportunities for innovation and efficiency in mixing practices.

Moreover, regular maintenance ensures the longevity and reliability of anchor impellers. Routine inspections for wear and tear, particularly on blade surfaces and weld joints, can preempt failures during critical production runs. Implementing a stringent maintenance schedule not only safeguards against unexpected downtime but also assures consistent product quality, reinforcing trustworthiness in production outputs. From a sustainability perspective, the efficiency of the anchor impeller can contribute to energy savings and a reduction in operational costs by minimizing the mixing time required to achieve desired results. An effective impeller reduces the energy expenditure of the mixing process, thus offering an eco-friendly edge that aligns with global sustainability goals. Incorporating feedback from experienced engineers and leveraging cutting-edge technology can revolutionize the design and use of anchor impellers. The integration of digital monitoring tools and sensors facilitates real-time analysis and adjustments, ensuring that mixing processes are continually refined for improved efficiency and output quality. In summary, the anchor impeller is a time-tested component in the realm of industrial mixing. Its applications are vast, its design is critical, and its optimization is key to achieving uniform mixtures, which are essential in producing high-quality end products. As industries continue to evolve, the adaptability and reliability of anchor impellers remain a testament to their indispensable role in manufacturing processes worldwide. Unlocking their full potential hinges on a harmonious blend of expertise, experience, and innovative advancements, driving continued excellence in the domain of mixing technologies.

Moreover, regular maintenance ensures the longevity and reliability of anchor impellers. Routine inspections for wear and tear, particularly on blade surfaces and weld joints, can preempt failures during critical production runs. Implementing a stringent maintenance schedule not only safeguards against unexpected downtime but also assures consistent product quality, reinforcing trustworthiness in production outputs. From a sustainability perspective, the efficiency of the anchor impeller can contribute to energy savings and a reduction in operational costs by minimizing the mixing time required to achieve desired results. An effective impeller reduces the energy expenditure of the mixing process, thus offering an eco-friendly edge that aligns with global sustainability goals. Incorporating feedback from experienced engineers and leveraging cutting-edge technology can revolutionize the design and use of anchor impellers. The integration of digital monitoring tools and sensors facilitates real-time analysis and adjustments, ensuring that mixing processes are continually refined for improved efficiency and output quality. In summary, the anchor impeller is a time-tested component in the realm of industrial mixing. Its applications are vast, its design is critical, and its optimization is key to achieving uniform mixtures, which are essential in producing high-quality end products. As industries continue to evolve, the adaptability and reliability of anchor impellers remain a testament to their indispensable role in manufacturing processes worldwide. Unlocking their full potential hinges on a harmonious blend of expertise, experience, and innovative advancements, driving continued excellence in the domain of mixing technologies.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS