Mobile:+86-311-808-126-83

Email:info@ydcastings.com

aluminum melting

The Melting Process of Aluminum An Overview

Aluminum, the third most abundant element in the Earth's crust, plays a crucial role in various industries due to its lightweight, corrosion-resistant properties, and recyclability. The melting of aluminum is a vital process in its production and utilization, and understanding this process is essential for manufacturers and engineers alike.

The Importance of Melting Aluminum

Melting aluminum is the first step in aluminum casting, forming, and recycling. The melting process allows for the transformation of solid aluminum into a molten state, which can then be easily poured into molds to create a variety of shapes and products. Furthermore, recycling aluminum is highly energy efficient compared to producing primary aluminum from ore. Melting recycled aluminum requires about 5% of the energy needed to produce new aluminum, making it an environmentally friendly choice.

The Melting Point of Aluminum

Aluminum has a relatively low melting point for a metal, approximately 660.3 degrees Celsius (1220.5 degrees Fahrenheit). This property makes aluminum easier to work with compared to metals like iron or copper, which require significantly higher temperatures for melting. The lower melting point also facilitates recycling efforts, as it allows for quick processing of scrap aluminum without extensive energy consumption.

The Melting Process

The melting of aluminum generally involves the following steps

1. Collection and Preparation Scrap aluminum is collected and sorted to separate it from other materials. Contaminants like plastics, rubber, and other metals must be removed to ensure the quality of the final product.

aluminum melting

2. Charging the Furnace The cleaned aluminum is then charged into a furnace. Various types of furnaces can be used for melting aluminum, including induction furnaces, resistance furnaces, and electric arc furnaces. Induction furnaces are particularly popular due to their efficiency and ability to provide uniform heating.

3. Melting Once the aluminum is inside the furnace, it is heated until it reaches its melting point. Depending on the method and furnace type, the heating can take anywhere from a few minutes to several hours. During this phase, care must be taken to prevent oxidation, as aluminum can react with oxygen at high temperatures, forming aluminum oxide.

4. Degassing and Refining After the aluminum has melted, impurities and gases that may have been absorbed during the melting process must be removed. This is often done by injecting inert gases like argon or nitrogen into the molten aluminum to facilitate the release of unwanted gases.

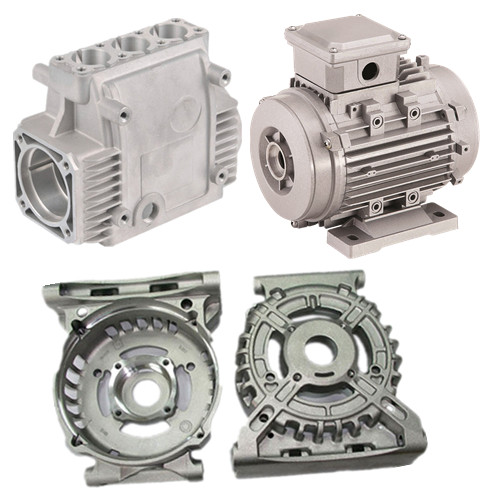

5. Pouring and Casting Once the molten aluminum is free of impurities, it is ready to be poured into molds. At this stage, the molten aluminum can take on various forms, from sheets and extrusions to complex cast shapes. The choice of mold will depend on the desired final product.

6. Cooling and Solidification After the aluminum has been poured into molds, it must cool and solidify. This cooling process can vary based on the nature of the casting and the desired properties of the final product. Controlled cooling can help enhance the mechanical properties of aluminum components.

Applications of Melted Aluminum

Once aluminum has been melted and cast, it can be used in countless applications. Its lightweight nature makes it ideal for aerospace and automotive industries, where reducing weight can lead to better fuel efficiency. Additionally, aluminum's durability and resistance to corrosion make it a preferred choice for construction materials, packaging, and consumer goods.

Conclusion

The melting of aluminum is a critical process that not only facilitates the manufacturing of aluminum products but also contributes significantly to recycling efforts. By understanding the intricacies of this process, industries can optimize their operations, reduce energy consumption, and produce high-quality aluminum products that meet the demands of modern applications. As the global focus on sustainability increases, the importance of efficient aluminum melting and recycling will continue to grow, making this process indispensable in today’s economy.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025