Mobile:+86-311-808-126-83

Email:info@ydcastings.com

aluminum centrifugal casting

The Advantages and Applications of Aluminum Centrifugal Casting

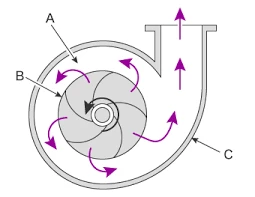

Centrifugal casting is a manufacturing process that has gained popularity across various industries due to its ability to produce high-quality metal components with superior properties. Aluminum centrifugal casting, in particular, is a method that utilizes centrifugal force to distribute molten aluminum into a rotating mold, resulting in improved density and structural integrity of the final product. This article explores the advantages of aluminum centrifugal casting and its diverse applications.

Advantages of Aluminum Centrifugal Casting

One of the primary benefits of aluminum centrifugal casting is the uniform density achieved through the process. The centrifugal force pushes impurities and gas bubbles toward the center of the mold, resulting in denser and stronger castings. This is particularly significant for components that will experience high stress or strain, ensuring reliability and durability in their performance.

Another advantage is the dimensional accuracy and surface finish that aluminum centrifugal casting can provide. The process allows for tighter tolerances and smoother surfaces compared to traditional sand casting. This precision reduces the need for extensive machining and finishing operations, thereby lowering production costs and time.

Moreover, aluminum is inherently lightweight and has excellent corrosion resistance. When these properties are combined with the strength achieved through centrifugal casting, manufacturers can create components that are not only strong but also lightweight and resistant to environmental degradation. This characteristic is particularly advantageous in industries such as automotive and aerospace, where weight reduction can lead to improved fuel efficiency and performance.

Additionally, the versatility of aluminum centrifugal casting allows for the production of a wide range of components. The process can be used to create both small and large parts, from fittings and housings to larger industrial components, like pipes and cylinders. This versatility opens up numerous possibilities for applications in various sectors, including automotive, aerospace, and energy.

aluminum centrifugal casting

Applications of Aluminum Centrifugal Casting

Aluminum centrifugal casting finds its way into many critical applications. In the automotive industry, it is used to produce components such as cylinder heads, engine blocks, and transmission cases. These castings benefit from the high strength-to-weight ratio of aluminum, which helps improve vehicle performance while reducing overall weight.

In aerospace, aluminum centrifugal casting is employed to manufacture components that require high strength and reliability. Parts such as engine mounts, brackets, and structural components are often made using this method to ensure they can withstand the rigorous demands of flight.

The energy sector also utilizes aluminum centrifugal casting for components such as turbine housings and pump casings. These components need to withstand high pressures and temperatures, making the enhanced properties of centrifugal castings ideal for such applications.

Furthermore, the electrical industry benefits from aluminum centrifugal casting through the production of high-quality rotor bars and stator frames for motors and generators. The improved conductivity and strength of aluminum castings help enhance the performance and efficiency of electric machines.

Conclusion

Aluminum centrifugal casting is a powerful manufacturing method that offers numerous advantages, including enhanced density, dimensional accuracy, and lightweight characteristics. Its application across various industries, from automotive to aerospace and energy, showcases its versatility and capability to produce high-quality components. As technology advances and the demand for lightweight yet strong materials continues to rise, aluminum centrifugal casting is likely to play an increasingly vital role in the future of manufacturing.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025