Mobile:+86-311-808-126-83

Email:info@ydcastings.com

aluminium investment casting

The Role of Aluminium Investment Casting in Modern Manufacturing

Aluminium investment casting, an advanced manufacturing process, has gained remarkable popularity in various industries. This technique combines the benefits of both casting and machining, enabling the production of complex shapes with high dimensional accuracy and quality. As industries continue to demand lighter, stronger, and more efficient materials, aluminium investment casting has emerged as a preferred method for producing intricate components in sectors such as aerospace, automotive, and electronics.

Process Overview

The investment casting process, often referred to as lost-wax casting, involves several key steps. Initially, a wax pattern of the desired component is created. This pattern is coated with a ceramic shell to form a mold. Once the shell hardens, the wax is melted and drained away, leaving a hollow cavity in the shape of the desired part. Molten aluminium is then poured into the mold, allowing it to cool and solidify into the final product. After cooling, the ceramic shell is removed, revealing the intricately cast aluminium component.

This method offers several advantages over traditional casting techniques. Firstly, investment casting can produce components with complex geometries that would be difficult, if not impossible, to achieve with other methods. Additionally, it provides a smooth surface finish, often requiring little to no machining after casting. This efficiency reduces overall production costs and time, making it an attractive option for manufacturers.

Advantages of Aluminium Investment Casting

1. Weight Reduction One of the main reasons industries are gravitating towards aluminium is its lightweight nature. Compared to steel and other metals, aluminium can reduce the weight of components significantly, which is crucial in industries like aerospace and automotive, where weight savings can lead to improved fuel efficiency and performance.

2. Corrosion Resistance Aluminium exhibits excellent resistance to corrosion, especially when compared to iron and steel. This property is particularly beneficial for components exposed to harsh environmental conditions, ensuring longevity and reliability.

3. Thermal and Electrical Conductivity Aluminium’s high thermal and electrical conductivity makes it an ideal choice for electrical applications, such as heat sinks and electrical housings, where efficient heat dissipation or electrical connection is essential.

4. Recyclability The recyclable nature of aluminium aligns with modern sustainability goals. As industries strive to minimize their environmental impact, choosing materials that can be reused and recycled is a significant advantage.

aluminium investment casting

5. Precision and Quality The investment casting process allows for tight tolerances, which is essential for high-performance applications. The quality of the cast parts meets stringent industry standards, ensuring reliability and durability in critical applications.

Applications in Various Industries

Aluminium investment casting finds applications across a diverse array of sectors

- Aerospace Lightweight and high-strength components are crucial for aircraft. Parts such as structural frames, brackets, and engine components made from aluminium investment casting contribute to overall efficiency and performance.

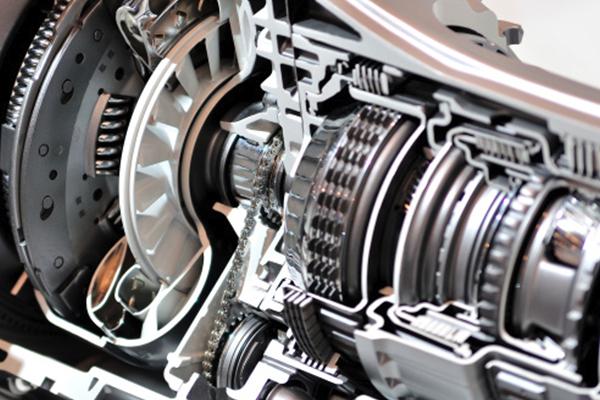

- Automotive The automotive industry requires precision-engineered components to improve fuel economy. Cast aluminium parts such as engine blocks, transmission housings, and suspension components are commonly produced using this method.

- Electronics With the increasing demand for compact and efficient electronic devices, investment casting allows manufacturers to create complex housings and heat sinks that meet strict design requirements.

- Industrial Equipment Many industrial machines and tools require durable parts that can withstand heavy loads and abrasive environments. Aluminium investment casting provides the strength and durability needed for these applications.

Conclusion

In conclusion, aluminium investment casting is a vital technology that meets the demands of modern manufacturing. Its ability to produce lightweight, complex, and high-precision components makes it an invaluable process across multiple industries. As technology advances and industries increasingly prioritize sustainability, the role of aluminium investment casting will continue to expand, driving innovations and enhancing performance in the manufacturing sector.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025