Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Optimizing Efficiency with Aluminum Impellers for Enhanced Performance in Fluid Dynamics Applications

The Role of Aluminium Impellers in Modern Engineering A Comprehensive Overview

Aluminium impellers have emerged as a cornerstone in various engineering applications, particularly within the fields of fluid dynamics and mechanical engineering. As components designed to enhance the efficiency of pumps and turbines, aluminium impellers offer numerous advantages that have made them increasingly popular in recent years. This article delves into the properties, manufacturing processes, advantages, applications, and future trends associated with aluminium impellers.

Properties of Aluminium

Aluminium is renowned for its unique set of physical and chemical properties, which make it an excellent material for impellers. Firstly, aluminium is lightweight compared to other metals, making it ideal for applications where weight reduction is critical. This quality allows for more efficient energy use and easier handling during installation and maintenance.

Moreover, aluminium exhibits excellent corrosion resistance, particularly when treated with protective coatings. This is especially beneficial in environments where exposure to water or chemicals is prevalent, such as in wastewater treatment facilities or marine applications. The thermal conductivity of aluminium also plays a crucial role, as it enables effective heat dissipation, which is vital for maintaining operational efficiency in high-temperature scenarios.

Manufacturing Processes

The production of aluminium impellers typically involves various manufacturing techniques, including casting, forging, and machining. Among these, investment casting is one of the most commonly used methods for creating intricate designs with high precision. This process allows for complex geometries while minimizing waste material, making it a cost-effective solution for mass production.

Another popular method is die casting, which further enhances the dimensional accuracy of the impellers. In this process, molten aluminium is injected into a mold under high pressure, producing components that require minimal post-processing. Machining, on the other hand, is often employed for more specialized applications where high tolerances are necessary.

Advantages of Aluminium Impellers

The adoption of aluminium impellers comes with a range of significant benefits. One of the most prominent advantages is their enhanced performance in terms of efficiency. The lightweight nature of aluminium reduces the overall inertia of the impeller, allowing for faster acceleration and deceleration in fluid systems. This leads to improved energy efficiency and reduced power consumption.

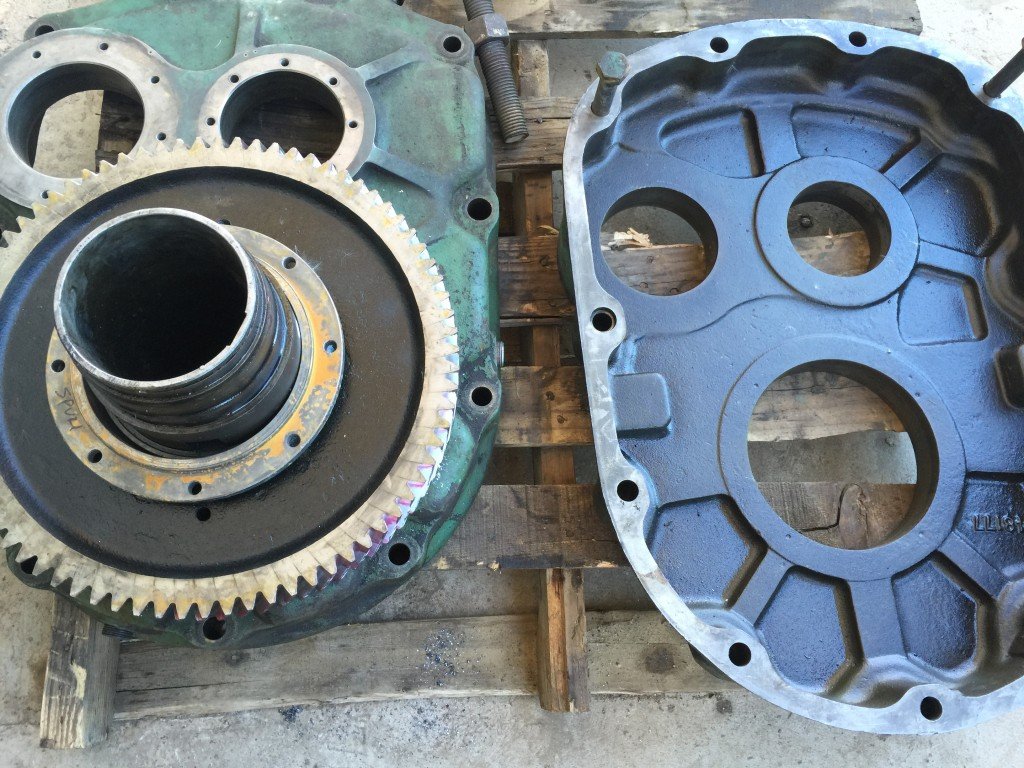

aluminium impeller

Additionally, aluminium impellers can be tailored to specific applications through advanced design techniques such as computational fluid dynamics (CFD). This ensures optimal flow characteristics, further enhancing the efficiency and performance of the system. The ability to incorporate advanced geometries, such as a highly curved blade design, allows for better fluid flow and reduced turbulence.

The economic aspect of aluminium impellers cannot be overlooked either; their lower material costs, coupled with the efficiencies gained in manufacturing processes, result in significant cost savings. The longevity and durability of aluminium, thanks to its corrosion resistance, also contribute to lower maintenance costs over the lifespan of the impeller.

Applications of Aluminium Impellers

Aluminium impellers find use in a wide range of applications across various industries. In the aerospace sector, they are utilized in jet engines and turbofan applications due to their light weight and efficiency. Marine industries leverage aluminium impellers for pumps used in water navigation and cooling systems.

Additionally, the HVAC (Heating, Ventilation, and Air Conditioning) sector benefits from aluminium impellers in fans and blowers, where effective airflow is essential. Furthermore, in the chemical industry, aluminium impellers are employed in agitators and mixers to enhance the mixing process.

Future Trends

The future of aluminium impellers points toward continued innovation and advancement. The integration of smart technology, including sensors and IoT devices, will likely enable real-time monitoring of performance metrics. This data-driven approach will facilitate predictive maintenance, leading to further improvements in efficiency and reliability.

Additionally, as the demand for sustainable practices increases, researchers are exploring the use of recycled aluminium in impeller production. This not only reduces the environmental impact of manufacturing but also aligns with the growing trend towards circular economy practices.

Conclusion

In conclusion, aluminium impellers represent a remarkable blend of efficiency, cost-effectiveness, and versatility that serves a variety of industries. Their unique properties and adaptability not only enhance system performance but also contribute to economic and sustainable practices. As we continue to innovate and improve upon traditional designs, aluminium impellers will undoubtedly play an increasingly vital role in shaping the future of engineering applications.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025