Mobile:+86-311-808-126-83

Email:info@ydcastings.com

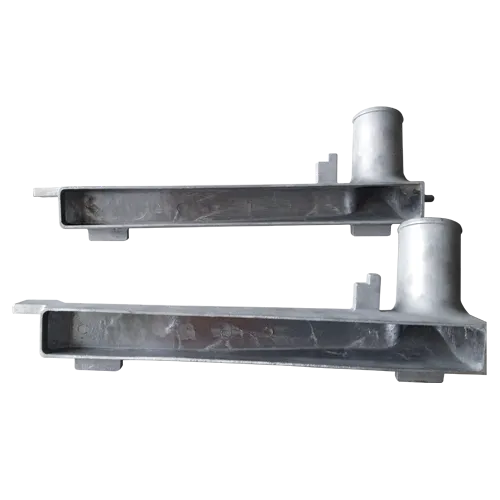

Aluminium Gravity Die Casting Techniques and Benefits for Precision Manufacturing Applications

Aluminium Gravity Die Casting An Overview

Aluminium gravity die casting is a highly efficient manufacturing process used to produce complex metal components with excellent dimensional accuracy and surface finish. This method involves pouring molten aluminium into a reusable metal die under the influence of gravity, which allows for the formation of intricate shapes with significantly reduced waste compared to other casting methods.

One of the primary advantages of aluminium gravity die casting is its ability to produce high volumes of components with consistent quality

. The use of durable metal dies means that castings can be produced in large quantities, making this process ideal for applications in various industries, including automotive, aerospace, and consumer goods. The reusability of the dies not only contributes to cost efficiency but also enhances the overall sustainability of the manufacturing process.Aluminium, as a casting material, offers numerous benefits. It is lightweight, making it an excellent choice for industries where reducing weight is crucial, such as automotive and aerospace. Additionally, aluminium exhibits excellent corrosion resistance, which is vital for products exposed to harsh environments. The thermal and electrical conductivity of aluminium also makes it suitable for applications in electronics and electrical components.

aluminium gravity die casting

The gravity die casting process begins with the preparation of the die, which is meticulously designed to accommodate the intended shape and features of the final product. Once the die is ready, molten aluminium is poured into the cavity, relying on gravity to fill the mold. The cooling rate of the casting affects the mechanical properties of the final product, thus careful control of the cooling process is essential.

After solidification, the casting is removed from the die, and any excess material, such as runners and gates, is trimmed off. The surface of the casting can be further treated through processes like machining, polishing, or coating to meet specific quality standards.

Despite its many advantages, aluminium gravity die casting does have limitations. The initial cost of creating the metal dies can be high, making the process less economical for small production runs. Additionally, the complexity of the part design may also influence the feasibility of this casting method.

In conclusion, aluminium gravity die casting is a versatile and efficient manufacturing process that enables the production of high-quality, lightweight components. Its benefits make it an attractive choice for industries requiring precision and durability in their products. As technology advances, the applications and efficiency of this casting method are likely to expand further, making it a key player in modern manufacturing.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025