Mobile:+86-311-808-126-83

Email:info@ydcastings.com

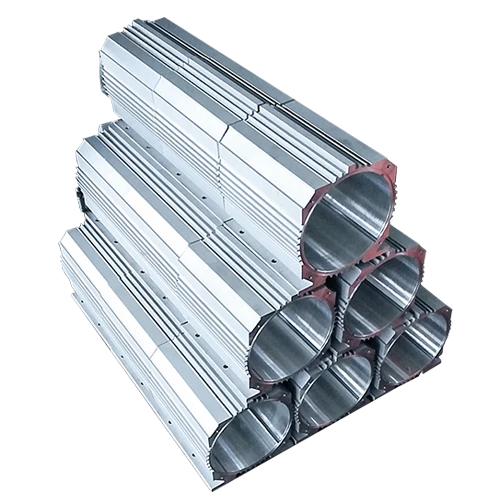

aluminium alloy investment casting

The Benefits of Aluminum Alloy Investment Casting

Aluminum alloy investment casting is a versatile manufacturing process that combines the benefits of aluminum's lightweight properties with the intricate design capabilities of investment casting. This technique allows for the production of complex geometries and precise tolerances, making it an ideal choice for various industries, including aerospace, automotive, and electronics.

One of the primary advantages of using aluminum alloys in investment casting is their excellent strength-to-weight ratio. Aluminum is significantly lighter than other metals, such as steel, yet it can still maintain a high level of structural integrity. This characteristic is particularly beneficial in the aerospace sector, where reducing weight is crucial for enhancing fuel efficiency and overall performance.

Additionally, aluminum alloys exhibit excellent corrosion resistance, which extends the lifespan of components. This property is especially advantageous in applications exposed to harsh environments, such as marine and automotive industries, where parts routinely face moisture and corrosive elements. The ability to cast intricate shapes with thin walls also allows designers to create lightweight components that do not compromise on strength.

aluminium alloy investment casting

The investment casting process itself offers numerous benefits. It enables producers to manufacture parts with excellent surface finishes and tight tolerances, often eliminating the need for extensive machining. This not only reduces production time but also decreases material waste, making it a more sustainable option compared to traditional manufacturing methods.

Moreover, aluminum alloy investment casting provides flexibility in design, allowing for the integration of complex features, such as internal cooling channels or intricate patterns, that would be difficult or impossible to achieve using other casting methods

. This capability opens up new possibilities for innovation, enabling engineers to develop more efficient and effective parts.As industries continue to seek lighter, stronger, and more durable materials, aluminum alloy investment casting stands out as a compelling solution. Its combination of strength, reduced weight, and design flexibility makes it an essential process for modern manufacturing. With ongoing advancements in casting technologies and alloy formulations, the future of aluminum investment casting looks promising, paving the way for even more applications and improved performance across a range of sectors.

In conclusion, aluminum alloy investment casting is not only a technical marvel but also a cornerstone of contemporary industrial practices. Its benefits underscore the importance of material innovation in meeting the demands of various fields while contributing to sustainability efforts.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025