Móvil:+86-311-808-126-83

Correo electrónico:info@ydcastings.com

Aluminium Metal Casting Services – Precision & Speed

Where Aluminium Metal Casting Meets Real-World Flange Performance

I was back in Hebei the other week, walking the shop floor at No.563 Xinhua Road, Shijiazhuang. You can smell the sand and cutting fluid. That’s where Aluminium Metal Casting isn’t just a buzzword—it’s a set of daily choices about alloys, tooling, and inspection that either make deadlines or break them.

Industry trends I’m seeing (and yes, they’re real)

Industry trends I’m seeing (and yes, they’re real)

- Lightweighting with A356-T6 and 3xx series alloys; still, for high-pressure flanges, cast steel and forgings dominate.

- Near-net-shape with digital gating simulation; CT and radiography for porosity mapping are becoming routine.

- Shorter lead times via modular tooling; to be honest, the best shops run PPAP-level documentation even outside automotive.

- Recyclability gains—aluminum reclaim loops with tighter melt control reduce inclusions and cost variation.

Process flow and testing—how the sausage is made

Process flow and testing—how the sausage is made

YD’s Flange line covers cast iron, cast steel, and forgings; for lightweight programs, Aluminium Metal Casting is applied to housings, covers, and select low-pressure flanges. Typical flow:

- Material: A356 (T6 heat treat), 6061 (forged), or per spec; for iron/steel, grades per ASTM/EN.

- Molding: green sand or no-bake; gravity/permanent mold for tighter CT grades; low-pressure die for better density.

- Heat treatment: T6 for aluminum; normalization or quench/temper for steel.

- Machining: CNC turning/boring; gasket faces Ra ≤ 3.2 μm typical.

- NDT and tests: Radiography per ASTM E1032, dye penetrant per ASTM E165, mag particle (ferrous) ASTM E1444, pressure leak per ISO 5208, tensile per ASTM B557 (Al).

- FAI/PPAP and traceability; CoC with heat lot and mechanicals.

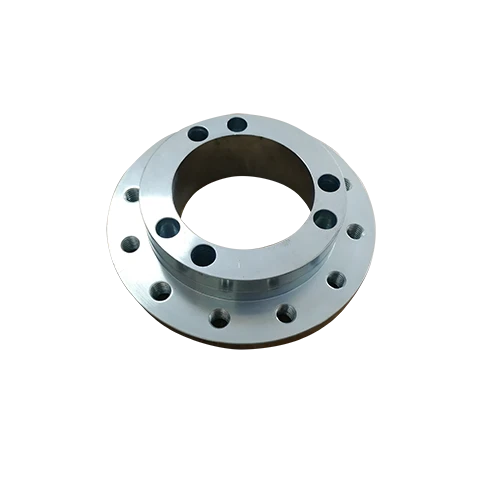

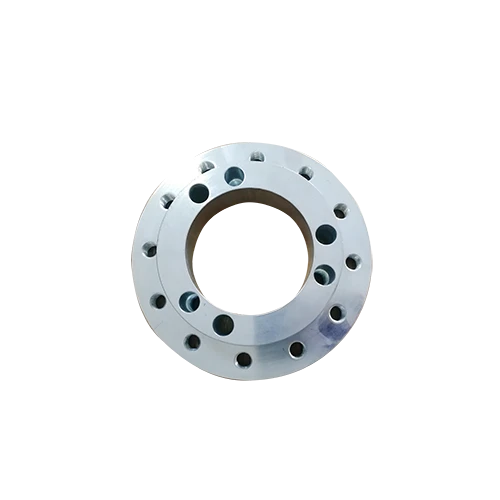

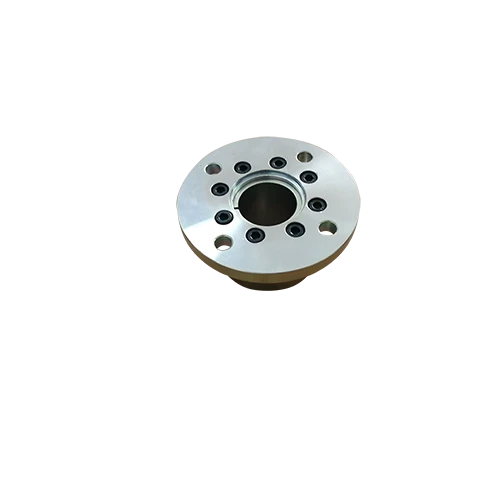

Product snapshot: Flange

| Product | Flange |

| Material | Cast iron, cast steel, forging; optional aluminum A356-T6 for low/medium pressure |

| Process | Casting, forging; machining to spec |

| Size range | φ100–800 mm |

| Standards | ASME B16.5 (flanges), ISO 8062-3 (casting tolerances) |

| Typical tolerance | CT8–CT10 (sand), CT6 (perm. mold) ≈ real-world may vary by geometry |

| Surface | Gasket face Ra ≤ 3.2 μm; coating on request |

| Service life | ≈ 15–25 years with proper media/coating; verify per duty cycle |

Quick test data (typical A356-T6 from last run): UTS ≈ 250 MPa, YS ≈ 170 MPa, Elong. ≈ 7%, porosity

Vendor snapshot (what buyers actually compare)

| Vendor | Certs | Lead time | NDT | MOQ |

|---|---|---|---|---|

| YD Castings (Hebei) | ISO 9001; PPAP on request | 20–35 days | RT, PT, MT | ≈ 50 pcs |

| Vendor B (regional) | ISO 9001 | 30–45 days | PT | 100 pcs |

| Vendor C (broker) | — | Varies | By request | — |

Applications, customization, and a quick case

Use cases I see weekly: pumps and valves, HVAC manifolds, food-grade pipework, mining slurry lines (steel), and, with Aluminium Metal Casting, EV cooling manifolds or lightweight compressor housings.

Customization path: RFQ → DFM review → Simulation and tooling → First Article Inspection → NPI ramp. Tolerances per ISO 8062-3; gasket geometry per ASME B16.5. Many customers say the DFM session saves a week of “why is this boss warping” emails.

Case study: a European OEM swapped a steel low-pressure coolant flange to A356-T6. Mass down 28%, leak-test to 1.2 MPa for 100k cycles, salt-spray 240 h after hard anodize. The kicker? Machining time dropped 35% because the casting was finally near-net.

Origin: No.563 Xinhua Road, Shijiazhuang City, Hebei Province, P.R. China. 050051.

Authoritative citations

- ASTM B26/B26M – Aluminum-Alloy Sand Castings; ASTM B108 – Permanent Mold Castings.

- ISO 8062-3 – Geometrical product specifications (GPS) – Tolerances for castings.

- ASME B16.5 – Pipe Flanges and Flanged Fittings.

- ASTM E1032 (Radiography), ASTM E165/E165M (Liquid Penetrant), ASTM E1444/E1444M (Magnetic Particle), ASTM B557 (Tension Testing of Aluminum Alloys).

- ASM Handbook, Vol. 15: Casting – process controls and defect analysis.

-

Materials Used in Manufacturing Cap End Pipe FittingsNoticiasNov.24,2025

-

Material Properties of CF8M CastingNoticiasNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNoticiasNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNoticiasNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNoticiasNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNoticiasNov.21,2025