Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Advanced Automotive Metal Casting & Processing Technologies-Hebei Yuanda Trade Co., Ltd.|High Pressure Casting&Die Casting

In the ever-evolving automotive industry, automobile accessories play a critical role in enhancing vehicle performance, safety, and efficiency. This article explores the latest advancements in metal casting and processing technologies, focusing on their impact on automotive part production. We'll examine the technical specifications, applications, and the company behind these innovations, while incorporating authoritative references from the National Institute of Standards and Technology (NIST).

Overview of Automotive Metal Casting Technologies

The automotive industry relies heavily on metal casting processes to produce critical components. According to NIST research, metallurgical advancements have significantly influenced manufacturing efficiency and product quality. Key technologies include:

- Casting Technology

- Die Casting Process

- Semi-Solid Processing

- Integrated Design Approaches

Casting Technology: Foundation of Automotive Manufacturing

Casting accounts for 15-20% of all automotive parts, primarily used for power system components and structural elements. Hebei Yuanda Trade Co., Ltd. specializes in high-quality casting solutions that align with global standards. European and American manufacturers lead in this field, utilizing digital technologies to achieve a scrap rate of 2-5%, as noted in NIST's manufacturing research.

Die Casting: Precision and Efficiency

Die casting is a cornerstone of modern automotive manufacturing. This high-pressure process produces precise parts with excellent dimensional accuracy. Key benefits include:

- Use of aluminum and zinc alloys

- Enhanced strength and durability

- Improved vehicle safety and reliability

According to NIST's materials research, die casting technologies have evolved to meet the industry's demand for lightweight yet robust components. Hebei Yuanda's expertise in this area ensures compliance with international quality standards.

Semi-Solid Processing: Innovating Magnesium Alloys

Semi-solid processing is revolutionizing the production of magnesium alloys, which are ideal for lightweight automotive applications. This technology enables casting wall thicknesses of 1-1.5mm and a mold slope of 1°-2°, as highlighted in NIST's advanced materials studies.

Integrated Design: The Future of Automotive Manufacturing

Integrated design approaches are becoming essential for reducing part weight and production costs. By optimizing structural designs, manufacturers can achieve lightweight, high-performance components. NIST's manufacturing innovation initiatives emphasize the importance of such strategies in sustainable automotive development.

Technical Specifications of Automotive Accessories

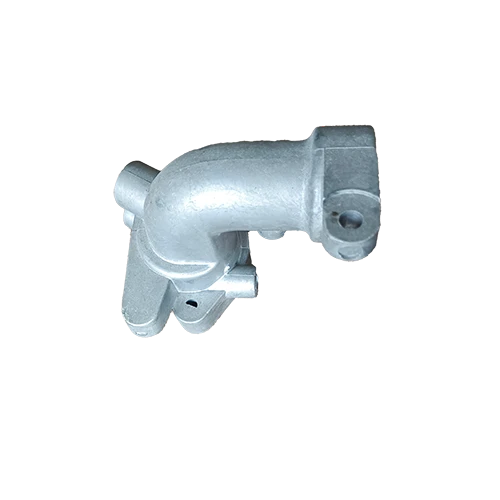

| Specification | Details |

|---|---|

| Material | ADC-12, A380 |

| Process | High-pressure casting |

| Weight Range | 0.5-2kg |

| Applications | Engine manifolds, water pumps, electric water pumps |

Applications in the Automotive Industry

These technologies are applied in various automotive components, including:

- Automobile Water Pumps

- Engine Manifolds

- Automotive Electric Water Pumps

Hebei Yuanda's automobile accessories are designed to meet the stringent requirements of modern vehicles, ensuring optimal performance and longevity.

About Hebei Yuanda Trade Co., Ltd.

As a leading manufacturer in the automotive industry, Hebei Yuanda Trade Co., Ltd. combines advanced technology with meticulous craftsmanship to deliver high-quality products. Their commitment to innovation is evident in their state-of-the-art facilities and rigorous quality control processes.

For more information about their automobile accessories, visit their official website.

Conclusion

The advancements in metal casting and processing technologies are transforming the automotive industry. By adopting these innovations, manufacturers like Hebei Yuanda Trade Co., Ltd. are setting new benchmarks for quality, efficiency, and sustainability. As NIST continues to drive research in materials science and manufacturing, the future of automotive technology looks increasingly promising.

References

National Institute of Standards and Technology (NIST) - Research on manufacturing technologies and materials science.

Hebei Yuanda Trade Co., Ltd. - Official website for product specifications and company information.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025