Mobile:+86-311-808-126-83

Email:info@ydcastings.com

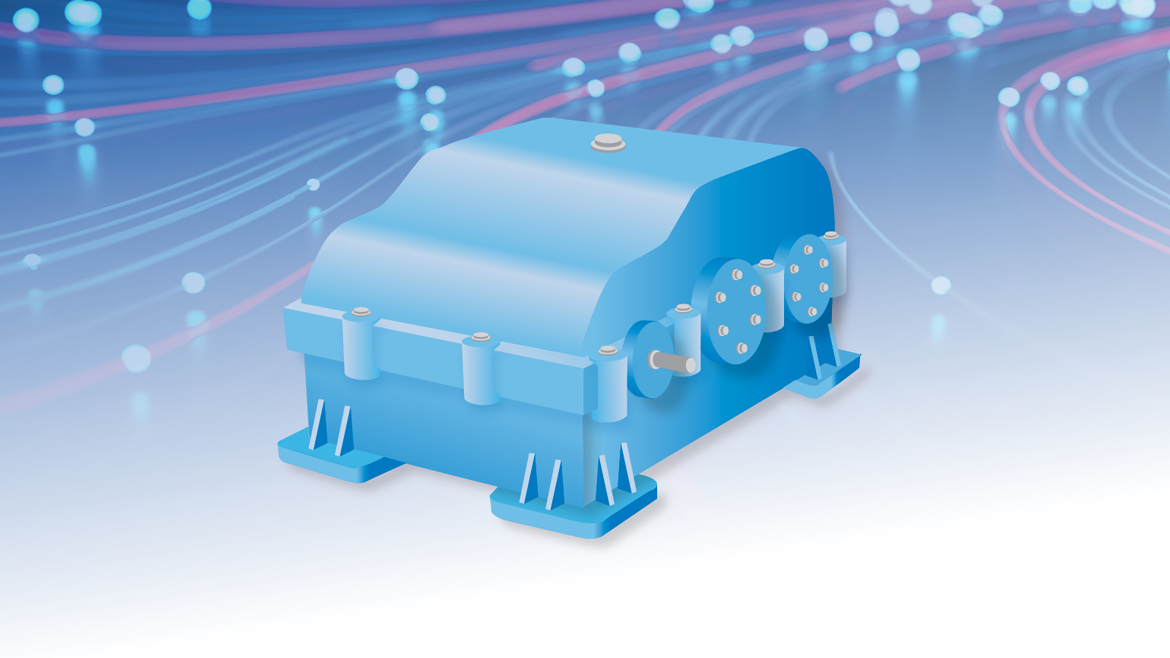

4 cylinder manifold

Understanding the 4% Cylinder Manifold A Comprehensive Overview

The 4% cylinder manifold is a vital component in various mechanical and engineering applications. It is predominantly utilized in power systems, particularly in engines and hydraulic systems where fluids are directed and controlled. The design, function, and efficiency of a cylinder manifold can significantly influence the performance of the entire system. In this article, we will explore the intricacies of the 4% cylinder manifold, its applications, advantages, and challenges.

What is a Cylinder Manifold?

A cylinder manifold is a device that collects, distributes, or modifies the flow of fluids—typically gases or liquids—within a system. It usually comprises several ports or channels through which the medium flows. The term 4% cylinder manifold typically refers to a design or configuration where a specific proportion (4%) of the manifold's volume is allocated for the efficient flow of working fluid. This can be significant when considering factors like pressure drop, speed of flow, and overall system efficiency.

Applications

The 4% cylinder manifold sees extensive usage across various industries. Here are a few notable applications

1. Automotive Engines In engines, cylinder manifolds play a crucial role in managing the air-fuel mixture entering the combustion chamber. An optimally designed manifold ensures even distribution, leading to better combustion efficiency and engine performance.

2. Hydraulic Systems In hydraulic machinery, cylinder manifolds help in directing the high-pressure fluid to various actuators and cylinders. The 4% design can enhance the responsiveness of the system, which is critical in heavy machinery such as excavators and cranes.

3. Aeronautics In aerospace engineering, cylinder manifolds are essential for managing fluid dynamics in various systems, including fuel delivery and hydraulic systems that control flight surfaces.

Advantages of the 4% Cylinder Manifold

4 cylinder manifold

The design of a 4% cylinder manifold comes with several advantages that improve system performance

1. Improved Flow Dynamics The specific allocation of 4% allows for optimized flow characteristics. This can lead to reduced turbulence and enhanced laminar flow, resulting in lesser energy loss and improved efficiency.

2. Enhanced System Responsiveness By facilitating better control over fluid distribution, the 4% cylinder manifold can lead to quicker responses in hydraulic systems, making them more reliable in critical applications.

3. Reduced Pressure Drops A well-designed manifold minimizes pressure drops along the flow path, which is particularly advantageous in hydraulic circuits. This reduction in pressure loss translates to lower energy consumption and improved overall performance.

4. Scalability The modular nature of manifold design allows for easy scalability. Whether scaling up for larger industrial applications or down for smaller machinery, the principles of the 4% design can be adapted accordingly.

Challenges

Despite its advantages, the 4% cylinder manifold is not without its challenges. Ensuring precision in manufacturing the manifolds is critical; any deviations can lead to performance issues. Additionally, maintaining the integrity of the manifold under extreme operational conditions—such as high pressures and fluctuating temperatures—is essential to prevent catastrophic failures.

Furthermore, as industries move toward more sustainable practices, the pressure is on engineers to develop cylinder manifolds that are not only efficient but also eco-friendly. This could mean utilizing alternative materials or designs that minimize resource consumption during production and operation.

Conclusion

In conclusion, the 4% cylinder manifold is a sophisticated and crucial component in various mechanical systems, with applications spanning numerous industries. Its design facilitates improved fluid dynamics, responsiveness, and efficiency, making it an integral part of modern engineering. As technology continues to evolve, so will the design and application of cylinder manifolds, pushing the boundaries of performance and sustainability. Understanding and optimizing such components will play a vital role in the advancement of engineering practices, ensuring that industries remain efficient and innovative in their processes.

-

Valve Body Acts as the “Heart” of Flow ControlNewsMay.19,2025

-

Understanding the Importance of ImpellersNewsMay.19,2025

-

Importance of Automobile Water PumpsNewsMay.19,2025

-

How an Engine Oil Pan Works to Keep Your Car LubricatedNewsMay.19,2025

-

Common Materials Used in Pump Impeller ManufacturingNewsMay.19,2025

-

Ball Valve Casting in Modern Pipeline SystemsNewsMay.19,2025