Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Jan. . 09, 2025 11:34

Back to list

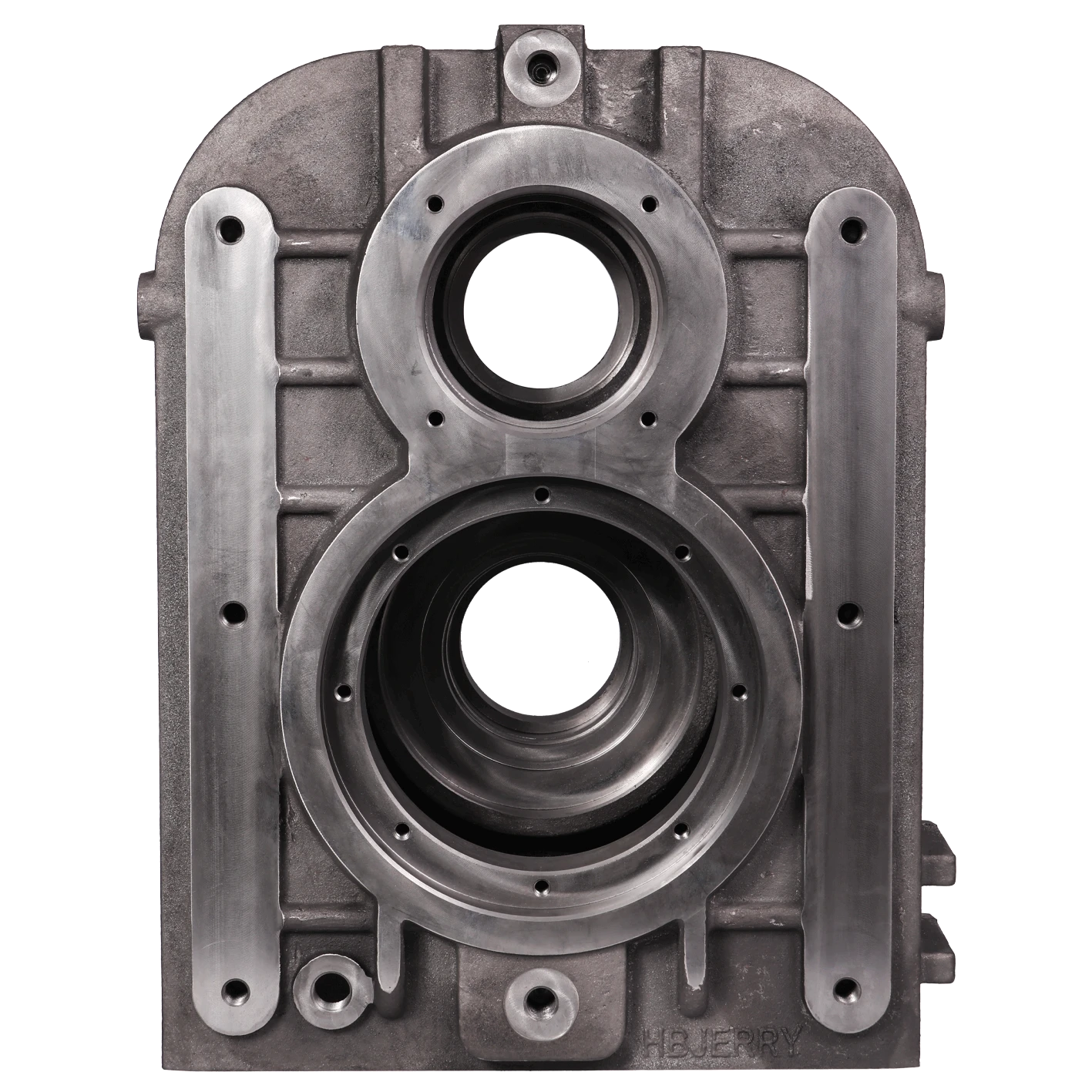

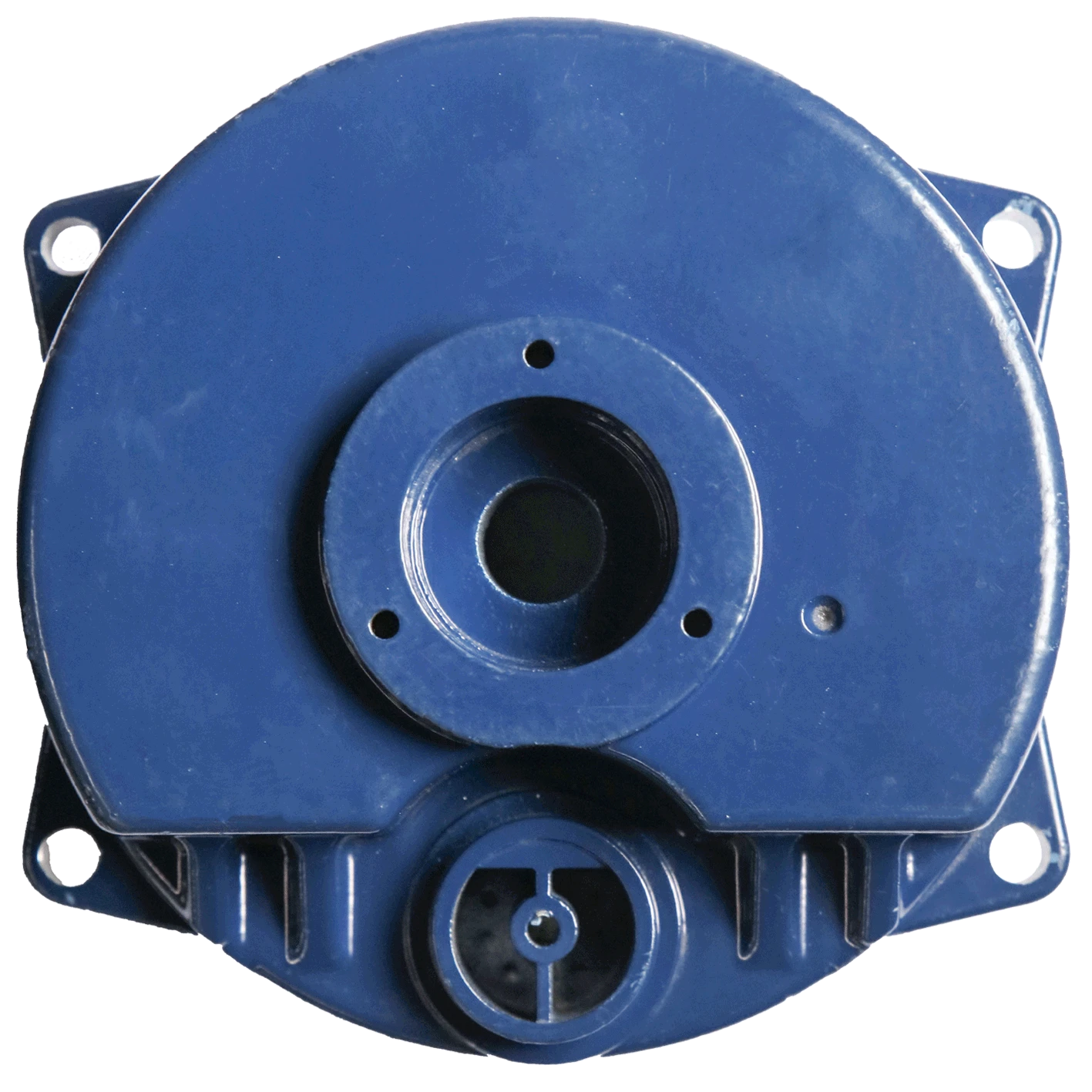

impeller

The impeller plays a crucial role in various sectors, serving as the driving force behind many mechanical and engineering applications. Its importance cannot be overstated, providing both efficiency and effectiveness in systems ranging from household appliances to large industrial machines. Through enhancing the movement of fluids in pumps and compressors, impellers are fundamental components, lending truth to the maxim that the heart of any machinery system beats with its impeller.

Additionally, the ongoing advancements in impeller technology highlight the importance of ongoing research and development. Computational fluid dynamics (CFD) has become a standard tool in the design and optimization of impellers, allowing engineers to model and simulate different designs to maximize efficiency and minimize energy use. By validating these models with empirical data collected from real-world scenarios, engineers develop solutions that meet both current and future needs. One of the hallmarks of a trustworthy product is its compliance with industry standards, something every user should consider when evaluating an impeller. Standards such as those set by the Hydraulic Institute or ISO provide guidelines ensuring performance, safety, and compatibility with existing systems. Adherence to these standards demonstrates a commitment to quality and reliability – a critical factor for any company aiming to maintain its competitive edge. It’s also imperative to consider the impact of an impeller's design on the environment, an area where expert knowledge and authority can lead to significant improvements. With modern impellers designed to decrease energy consumption and reduce carbon footprints, choosing the right impeller can significantly contribute to achieving sustainability goals. Engineers and firms dedicated to these principles ensure that their designs not only meet the immediate needs of their clients but also address longer-term environmental impacts. In conclusion, understanding and leveraging the engineering prowess inherent in impeller technology allows for the creation of efficient, reliable, and sustainable systems. These components are not only fundamental in their respective applications but also serve as a testament to human ingenuity in solving complex mechanical challenges. By prioritizing factors such as material choice, flow dynamics, compliance with industry standards, and environmental impact, users can select impellers that will meet their exacting needs, assuring them of both performance and peace of mind.

Additionally, the ongoing advancements in impeller technology highlight the importance of ongoing research and development. Computational fluid dynamics (CFD) has become a standard tool in the design and optimization of impellers, allowing engineers to model and simulate different designs to maximize efficiency and minimize energy use. By validating these models with empirical data collected from real-world scenarios, engineers develop solutions that meet both current and future needs. One of the hallmarks of a trustworthy product is its compliance with industry standards, something every user should consider when evaluating an impeller. Standards such as those set by the Hydraulic Institute or ISO provide guidelines ensuring performance, safety, and compatibility with existing systems. Adherence to these standards demonstrates a commitment to quality and reliability – a critical factor for any company aiming to maintain its competitive edge. It’s also imperative to consider the impact of an impeller's design on the environment, an area where expert knowledge and authority can lead to significant improvements. With modern impellers designed to decrease energy consumption and reduce carbon footprints, choosing the right impeller can significantly contribute to achieving sustainability goals. Engineers and firms dedicated to these principles ensure that their designs not only meet the immediate needs of their clients but also address longer-term environmental impacts. In conclusion, understanding and leveraging the engineering prowess inherent in impeller technology allows for the creation of efficient, reliable, and sustainable systems. These components are not only fundamental in their respective applications but also serve as a testament to human ingenuity in solving complex mechanical challenges. By prioritizing factors such as material choice, flow dynamics, compliance with industry standards, and environmental impact, users can select impellers that will meet their exacting needs, assuring them of both performance and peace of mind.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS