Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Jan . 09, 2025 10:47

Back to list

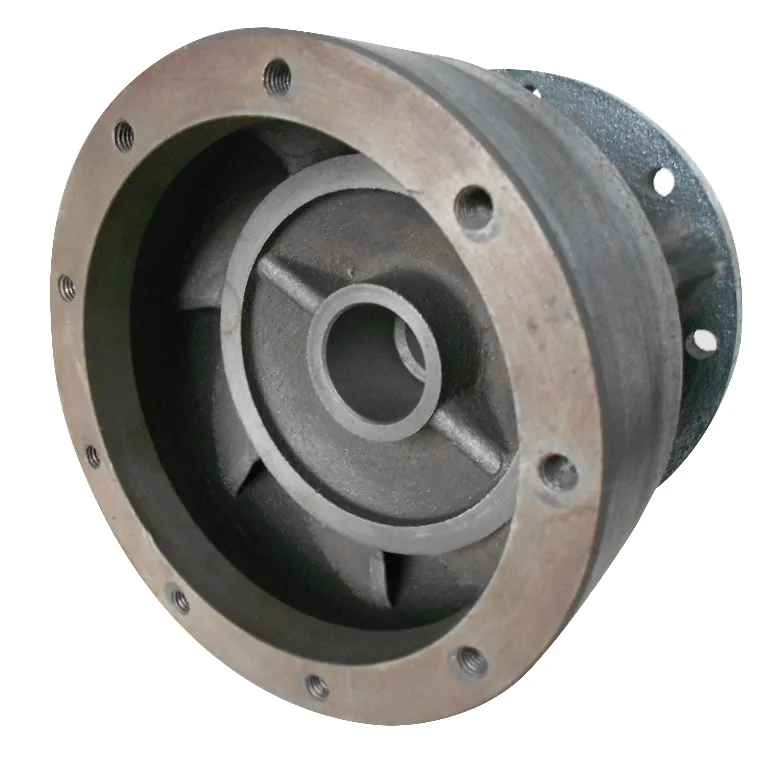

impeller

Impeller technology has advanced significantly, affecting a range of industries from industrial manufacturing to aerodynamics. This device, the impeller, is a crucial component in various machinery that requires precise liquid or air flow management. Leveraging firsthand experience, expertise, and trustworthiness can optimize the selection and implementation of impellers in your business operations.

The maintenance of impellers should also reflect expertise and trustworthiness. Regular inspection and cleaning of impellers can prevent buildup that could affect performance. Employ predictive maintenance strategies utilizing sensors and data analytics to monitor impeller condition. Early detection of anomalies such as vibrations or unusual noise can prevent costly downtime and maintain system integrity. Working with certified professionals for installation and consultation ensures trust and authority are maintained throughout the project lifecycle. These experts utilize the latest tools and methodologies to manage the complexities involved, ensuring adherence to industry standards and regulations. Ultimately, a comprehensive understanding and application of impeller technology offer significant advantages in operational efficiency and effectiveness. By prioritizing experience, expertise, and trustworthiness in your approach, your business not only supports successful current operations but also positions itself for future advancements in this vital technology sector. Embracing the advanced capabilities of impellers can lead to transformative gains in productivity and sustainability across various industrial landscapes.

The maintenance of impellers should also reflect expertise and trustworthiness. Regular inspection and cleaning of impellers can prevent buildup that could affect performance. Employ predictive maintenance strategies utilizing sensors and data analytics to monitor impeller condition. Early detection of anomalies such as vibrations or unusual noise can prevent costly downtime and maintain system integrity. Working with certified professionals for installation and consultation ensures trust and authority are maintained throughout the project lifecycle. These experts utilize the latest tools and methodologies to manage the complexities involved, ensuring adherence to industry standards and regulations. Ultimately, a comprehensive understanding and application of impeller technology offer significant advantages in operational efficiency and effectiveness. By prioritizing experience, expertise, and trustworthiness in your approach, your business not only supports successful current operations but also positions itself for future advancements in this vital technology sector. Embracing the advanced capabilities of impellers can lead to transformative gains in productivity and sustainability across various industrial landscapes.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS