Handy, Mobiltelefon:+86-311-808-126-83

Email:info@ydcastings.com

High-Performance Automobile Water Pump for Engine Cooling

The Crucial Role of Modern Automotive Fluid Dynamics

In the intricate world of automotive engineering, the efficiency and longevity of an internal combustion engine (ICE), or even the thermal management system of an electric vehicle (EV), are critically dependent on effective cooling. At the heart of this system is the auto wasserpumpe, a component often overlooked but indispensable for maintaining optimal operating temperatures. This device circulates coolant through the engine block, cylinder head, and radiator, dissipating heat generated during combustion and preventing catastrophic overheating. The evolution of this essential part reflects the broader advancements in material science, manufacturing precision, and electronic control, directly impacting vehicle performance, fuel efficiency, and emissions.

Modern engine designs, with their tighter tolerances and higher power outputs, place increasing demands on the cooling system. This has led to significant innovations in auto wasserpumpe technology, including the proliferation of automotive electric water pump solutions, which offer variable flow rates and enhanced efficiency compared to traditional belt-driven mechanical pumps. Understanding the technical intricacies and strategic implications of these components is vital for B2B stakeholders, from design engineers to procurement specialists, who aim to optimize vehicle systems for performance and durability.

Industry Trends and Technological Innovations

The automotive industry is undergoing a transformative shift, driven by stringent emission regulations and the rapid adoption of electric vehicles. These changes are profoundly influencing the design and function of the auto wasserpumpe.

- Electrification: The most prominent trend is the move towards the automotive electric water pump. Unlike mechanical pumps, an electric water pump for car can operate independently of engine speed, providing precise cooling on demand. This translates to quicker engine warm-up, reduced parasitic losses, improved fuel economy in ICE vehicles, and efficient thermal management for battery packs and power electronics in EVs.

- Advanced Materials: Manufacturers are increasingly utilizing lightweight composites, high-strength plastics, and corrosion-resistant alloys for impellers and housings. These materials reduce overall weight, enhance durability, and extend service life, particularly in environments exposed to various coolants and temperatures.

- Integrated Systems: Modern cooling systems are becoming more complex, integrating the water pump with other thermal management components like thermostats, valves, and heat exchangers into modular units. This simplifies assembly, reduces potential leak points, and allows for more sophisticated thermal control strategies.

- Smart Diagnostics: Next-generation water pumps are incorporating sensors for temperature, pressure, and flow rate, enabling real-time monitoring and predictive maintenance. This data can be integrated into the vehicle's onboard diagnostic (OBD) system, providing early warnings for potential failures and preventing costly damage.

These innovations not only enhance vehicle performance and reliability but also contribute significantly to environmental sustainability by improving efficiency and reducing maintenance waste. The shift towards an auto electric water pump is a clear indicator of the industry's direction.

Manufacturing Process Flow: Precision Engineering for Durability

The manufacturing of a high-quality auto wasserpumpe involves a meticulous process designed to ensure precision, durability, and optimal performance. This multi-stage process leverages advanced metallurgical and machining techniques.

Schematic Steps of Water Pump Production:

-

Material Selection & Preparation:

- Housings often utilize high-grade aluminum alloys or cast iron for mechanical strength and thermal conductivity. Impellers may be made from advanced plastics (e.g., PPS, PEEK) for lightweight and corrosion resistance, or brass/stainless steel for heavy-duty applications. Shafts are typically hardened steel.

- Raw materials undergo rigorous quality checks for composition and structural integrity before processing.

-

Casting/Forging of Housing Components:

- Aluminum housings are typically die-cast or gravity-cast to achieve intricate geometries and thin walls. Cast iron housings are often sand-cast.

- Forging may be used for certain high-stress components to enhance grain structure and mechanical properties.

-

CNC Machining:

- Post-casting/forging, components undergo precision CNC machining to achieve exact dimensions for bearing seats, seal surfaces, and mounting points. This ensures minimal runout and optimal sealing.

- High-precision tolerances are critical for the efficient operation and longevity of the pump.

-

Impeller Production:

- Plastic impellers are manufactured via injection molding, while metallic impellers may be cast, machined, or stamped. Each impeller is dynamically balanced to prevent vibration and cavitation.

-

Bearing and Seal Installation:

- High-quality sealed bearings (often double-row ball or roller bearings) are pressed into the housing.

- Mechanical seals, critical for preventing coolant leakage, are carefully installed. These seals typically consist of a stationary ceramic ring and a rotating carbon-graphite ring, ensuring a robust, low-friction barrier.

-

Assembly:

- The shaft, impeller, bearings, and seals are meticulously assembled into the pump housing. For automotive electric water pump models, the electric motor and control electronics are also integrated.

-

Testing and Quality Control:

- Each auto wasserpumpe undergoes rigorous testing based on international standards like ISO 9001, ISO/TS 16949 (automotive quality management), and ANSI/HI pump standards.

- Tests include leak detection (pressure decay, helium leak tests), flow rate and pressure performance, noise and vibration analysis, and endurance testing to simulate extreme operating conditions. This ensures a service life often exceeding 150,000 miles (240,000 km) for mechanical pumps and even longer for electric variants.

-

Finishing and Packaging:

- Final inspection, protective coating applications, and secure packaging for shipment to target industries such as automotive OEM, aftermarket, petrochemical, metallurgy, and water supply & drainage.

This rigorous process ensures that each pump exhibits critical advantages such as energy saving through optimized flow dynamics, superior corrosion resistance due to material selection, and extended operational reliability in diverse and demanding application scenarios.

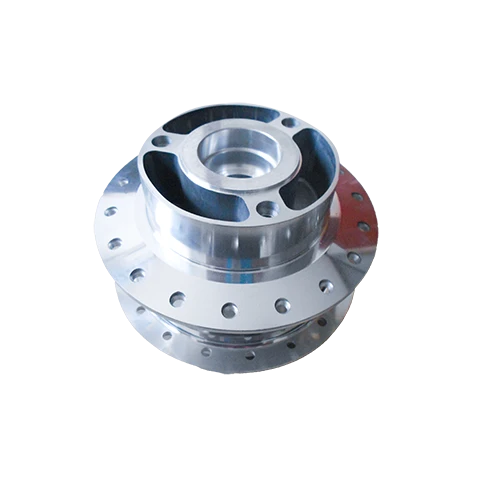

Image 1: Precision machining ensures optimal component fit and finish for the auto wasserpumpe.

Technical Specifications and Performance Parameters

Understanding the technical specifications of an auto wasserpumpe is crucial for selecting the right component for a specific application. Performance is dictated by several key parameters, which vary significantly between mechanical and automotive electric water pump designs.

Typical Water Pump Specifications:

| Parameter | Mechanical Water Pump (Typical) | Electric Water Pump (Typical) |

|---|---|---|

| Operating Voltage | N/A (Belt-driven) | 12V - 48V DC |

| Flow Rate Capacity | 80-200 Liters/Minute (engine speed dependent) | Variable, 5-250 Liters/Minute (demand dependent) |

| Max Head Pressure | 10-15 meters H₂O | 10-20 meters H₂O |

| Power Consumption | Parasitic loss from engine (~1-5 HP) | 20W - 250W (variable) |

| Operating Temperature Range | -40°C to +120°C | -40°C to +120°C |

| Typical Service Life | 100,000 - 150,000 miles | 150,000 - 200,000+ miles (or equivalent hours) |

| Control Mechanism | Mechanical (belt-driven) | PWM (Pulse Width Modulation) via ECU |

| Material (Housing) | Cast Iron, Aluminum Alloy | Aluminum Alloy, High-Performance Polymer |

These parameters highlight the performance advantages of an auto electric water pump, particularly its variable flow capability, which directly contributes to optimized thermal management and fuel efficiency. The ability to precisely control coolant flow independently of engine speed allows for significant energy savings by only operating the pump when necessary, and at the required speed.

Application Scenarios and Target Industries

The robust design and versatile performance characteristics of modern auto wasserpumpe solutions extend their utility beyond traditional passenger vehicles. Key target industries and application scenarios include:

- Automotive OEM & Aftermarket: Essential for passenger cars, light commercial vehicles, and heavy-duty trucks. The demand for both mechanical and automotive electric water pump units is constant, driven by new vehicle production and maintenance requirements.

- Heavy Equipment & Off-Highway: Construction machinery, agricultural vehicles, and mining equipment rely on durable water pumps for their high-stress, continuous operation. These environments often demand enhanced corrosion resistance and robust bearing systems.

- Marine Applications: Seawater cooling systems in marine engines require specialized pumps with superior corrosion resistance, often utilizing bronze or stainless steel impellers and housings.

- Industrial Power Generation: Stationary power generators, both diesel and gas-powered, require reliable cooling systems to maintain efficiency and prevent downtime.

- Petrochemical Industry: Pumps used in this sector must withstand corrosive chemicals and extreme temperatures, often requiring specialized materials and sealing technologies. The efficient cooling of process equipment is paramount.

- Metallurgy and Water Supply & Drainage: While primary focus is automotive, the underlying principles of fluid dynamics and robust pump design are transferable. For instance, in cooling large furnace components or circulating treatment chemicals, pumps need to manage high flow rates and aggressive media. The general reliability and material science expertise translate well.

- Electric Vehicles (EVs): Electric water pump for car applications are critical for thermal management of battery packs, electric motors, and power electronics, which often operate in precise temperature windows for optimal performance and longevity.

The adaptability of water pump technology, particularly the shift to controllable auto electric water pump systems, means greater precision in temperature regulation across all these diverse applications.

Technical Advantages and Performance Benefits

The latest generation of auto wasserpumpe designs, especially the rapidly evolving automotive electric water pump, offers a suite of compelling technical advantages:

- Enhanced Fuel Efficiency (ICE): By decoupling the pump speed from engine RPM, electric pumps can operate only when necessary and at the optimal speed, reducing parasitic drag on the engine. This can lead to a 1-3% improvement in fuel economy.

- Precise Temperature Control: Ein electric water pump for car allows for highly accurate coolant flow based on real-time thermal demands from various engine zones, including engine manifolds and cylinder heads. This ensures faster engine warm-up, precise temperature regulation during operation, and improved emissions control.

- Extended Component Lifespan: Maintaining stable operating temperatures reduces thermal stress on engine components, seals, and hoses, contributing to longer engine life. Furthermore, the absence of belt-driven forces reduces wear on bearings.

- Reduced Emissions: Optimal temperature control enables catalytic converters to reach operating temperature faster and function more efficiently, reducing harmful tailpipe emissions, particularly during cold starts.

- Greater Design Flexibility: The compact nature and independent operation of an auto electric water pump offer greater flexibility in engine bay packaging and allows for more sophisticated thermal management strategies in hybrid and electric vehicles.

- Corrosion Resistance & Durability: Through advanced material selection (e.g., engineered polymers, specialized alloys) and robust sealing technologies, modern pumps offer superior resistance to corrosion from coolants and reduced wear from cavitation.

- Quiet Operation: Electric pumps generally produce less noise and vibration compared to their mechanical counterparts, contributing to overall vehicle refinement.

Vendor Comparison and Market Landscape

Der Markt für auto wasserpumpe solutions is highly competitive, featuring established global players and innovative niche manufacturers. Selecting the right vendor involves evaluating factors like manufacturing capabilities, R&D investment, quality certifications, and global supply chain reliability.

Comparative Analysis of Leading Water Pump Manufacturers (Illustrative):

| Feature | Vendor A (Global OEM Supplier) | Vendor B (Specialist EWP Producer) | Vendor C (Aftermarket Focused) |

|---|---|---|---|

| Primary Focus | Mechanical & Electric OEM | High-Performance Electric Water Pump for Car | Replacement Mechanical Pumps |

| R&D Investment | High (innovative materials, control) | Very High (motor tech, smart integration) | Moderate (cost-effective alternatives) |

| Quality Certifications | IATF 16949, ISO 14001, OHSAS 18001 | IATF 16949, ISO 9001 | ISO 9001 |

| Customization Capability | Extensive, collaborative design | Moderate to High, specific applications | Limited, standard fits |

| Market Share (Est.) | Significant, Tier 1 supplier | Growing, innovative leader | Solid, cost-effective provider |

| Typical Lead Time (OEM projects) | 12-18 months (design to production) | 8-14 months (specialized EWP) | 2-4 months (standard part sourcing) |

Choosing a vendor depends heavily on the specific project requirements, whether it's for high-volume OEM production of advanced auto electric water pump units, specialized industrial applications, or robust aftermarket support.

Customized Solutions and Collaborative Engineering

For specialized automotive platforms, industrial machinery, or unique thermal management challenges, off-the-shelf auto wasserpumpe solutions may not suffice. Leading manufacturers offer comprehensive customized solutions, engaging in collaborative engineering to meet precise performance envelopes. This often involves:

- Application-Specific Design: Tailoring pump housing dimensions, impeller geometry, and seal types to fit unique engine bay constraints or fluid compatibility requirements, such as for advanced coolants or high-pressure systems.

- Material Optimization: Selecting specific alloys (e.g., inconel for extreme temperatures, specialized polymers for aggressive chemicals) or coatings to enhance corrosion resistance and durability in harsh operating environments.

- Integrated Control Systems: Developing bespoke electronic control units (ECUs) and software for automotive electric water pump applications, enabling seamless integration with the vehicle's broader thermal management architecture and communication protocols (e.g., CAN bus). This can include variable speed control logic optimized for specific drive cycles or cooling demands.

- Performance Tuning: Calibrating flow rates, head pressure, and efficiency curves to align perfectly with the thermal load characteristics of particular engines or EV battery packs. This ensures optimal thermal stability across the full operating range.

- NVH (Noise, Vibration, Harshness) Optimization: Designing pump components and mounting solutions to minimize noise and vibration, crucial for premium vehicles and specialized industrial applications.

This bespoke approach ensures that the auto wasserpumpe is not merely a component, but an integral, optimized part of a larger, high-performance system.

Image 2: Disassembled auto wasserpumpe components showcasing intricate design and robust construction.

Application Case Studies: Proving Performance in Practice

Case Study 1: Heavy-Duty Truck Fleet Upgrade

A major logistics company operating a fleet of heavy-duty trucks faced persistent issues with engine overheating during long-haul operations, particularly in mountainous terrains. Traditional mechanical water pumps struggled to deliver consistent flow rates under varying engine loads and speeds. After consulting with a leading pump manufacturer, the fleet opted to upgrade to a robust automotive electric water pump system specifically designed for heavy-duty applications.

- Solution: Installation of an intelligent auto electric water pump capable of variable flow rates controlled by the engine's ECU, continuously monitoring coolant temperature and load.

-

Results:

- Reduction in engine overheating incidents by 90% over a 12-month period.

- Average fuel efficiency improvement of 2.5% due to reduced parasitic drag.

- Extended service intervals for coolant systems by 15%, reducing maintenance costs.

- Positive driver feedback regarding more stable engine temperatures and reduced thermal alarms.

Case Study 2: Performance EV Thermal Management

An emerging electric vehicle manufacturer required a highly efficient and compact electric water pump for car to manage the critical thermal demands of its high-performance battery pack and electric drivetrain. The challenge was to maintain precise temperature ranges under aggressive driving conditions without compromising battery range or vehicle weight.

- Solution: A custom-designed, multi-stage automotive electric water pump system with integrated sensors and a dedicated thermal ECU. The pump utilized lightweight composite materials and a high-efficiency brushless DC motor.

-

Results:

- Maintained battery pack temperature within +/- 1°C of optimal during track testing.

- Achieved target motor efficiency and extended power output periods without derating.

- Total cooling system weight reduction by 1.8 kg compared to initial estimates.

- Contributed to a verified 5% increase in usable battery range under demanding conditions by optimizing thermal losses.

Image 3: Final assembly and testing of an auto wasserpumpe unit.

Quality Assurance and Authoritative Certifications

Our commitment to engineering excellence is underpinned by rigorous quality assurance protocols and adherence to the highest industry standards. As a trusted partner for B2B clients, we ensure that every auto wasserpumpe component meets or exceeds expectations for performance, reliability, and longevity.

- ISO 9001:2015 Certified: Our quality management system is certified to ISO 9001, demonstrating our consistent ability to provide products and services that meet customer and regulatory requirements.

- IATF 16949 Compliant: For automotive applications, our processes align with IATF 16949, emphasizing continuous improvement, defect prevention, and reduction of variation and waste in the supply chain.

- Advanced Testing Facilities: Utilizing state-of-the-art test benches for flow rate, pressure, cavitation, endurance, thermal cycling, and noise/vibration analysis to validate design and manufacturing integrity. Each pump undergoes 100% leak testing.

- Material Traceability: Full traceability of raw materials and components ensures accountability and facilitates rapid response to any material-related issues.

- Strategic Partnerships: Collaborating with Tier 1 automotive suppliers and leading engineering firms allows us to integrate cutting-edge technologies and best practices into our product development and manufacturing. Our products have been integrated into vehicles from leading global manufacturers for over a decade.

These certifications and practices underscore our authoritativeness in the manufacturing of critical automotive components, instilling confidence in our partners.

Frequently Asked Questions (FAQ)

Q: What is the primary advantage of an automotive electric water pump over a mechanical one?

A: The primary advantage is variable flow rate control, independent of engine speed. This allows for precise thermal management, faster engine warm-up, reduced parasitic losses, and improved fuel efficiency and emissions. It's particularly crucial for advanced ICE and EV applications.

Q: How does material selection impact auto wasserpumpe longevity?

A: High-quality materials like engineered polymers for impellers and corrosion-resistant aluminum alloys for housings significantly enhance pump longevity by resisting wear from cavitation, corrosion from coolants, and thermal stress. This ensures extended service life and reduces the risk of premature failure.

Q: Are your products compatible with advanced coolants and high-temperature applications?

A: Yes, our auto wasserpumpe products are engineered and tested for compatibility with a wide range of modern long-life coolants and are designed to operate reliably within the demanding temperature ranges of contemporary engines and EV thermal systems. Specific material choices can be customized for extreme applications.

Q: What testing standards do your water pumps adhere to?

A: Our manufacturing and testing processes comply with international standards such as ISO 9001 and IATF 16949. Products undergo rigorous performance, durability, and leak testing to meet or exceed OEM specifications and industry benchmarks like ANSI/HI.

Lead Time, Fulfillment, and Warranty Commitments

Lead Time & Fulfillment:

Our streamlined manufacturing processes and robust supply chain enable efficient order fulfillment. For standard auto wasserpumpe models, typical lead times range from 4-8 weeks, depending on order volume and current production schedules. Custom-engineered solutions or new product development projects typically have a lead time of 8-16 months from design finalization to initial production batches, considering the complexity of tooling and validation. We maintain strong inventory management for critical raw materials and components to mitigate supply chain disruptions.

Warranty Commitments:

We stand behind the quality and reliability of our auto wasserpumpe products. All pumps are covered by a comprehensive warranty against defects in materials and workmanship. Standard warranty periods for OEM applications typically range from 24 months/50,000 miles to 36 months/75,000 miles, with extended warranty options available for specific contracts. For automotive electric water pump units, warranties often extend to 5 years or 100,000 miles, reflecting their enhanced durability. Details are provided in individual supply agreements.

Customer Support & After-Sales Service:

Our commitment to our B2B partners extends well beyond delivery. We offer dedicated technical support, including expert advice on installation, troubleshooting, and maintenance. Our global network ensures prompt access to spare parts and service professionals, minimizing downtime and maximizing operational continuity for your vehicles and industrial equipment. Regular product training and technical bulletins are also provided to ensure our partners are always up-to-date with the latest advancements in electric water pump for car technology.

Conclusion

Der auto wasserpumpe remains a cornerstone of vehicle and industrial engine thermal management, evolving significantly to meet the demands of modern high-efficiency and electrified powertrains. From its meticulous manufacturing process, involving advanced casting and CNC machining, to its critical role in energy saving and corrosion resistance, the pump is a testament to precision engineering. The ongoing shift towards the automotive electric water pump underscores an industry-wide commitment to greater efficiency, control, and sustainability. By partnering with manufacturers dedicated to cutting-edge technology, rigorous quality, and comprehensive support, B2B stakeholders can ensure optimal performance and longevity for their critical applications.

Citations:

- SAE International. "Thermal Management in Hybrid and Electric Vehicles." (Referenced articles from SAE World Congress proceedings on electric water pump control strategies).

- International Organization for Standardization (ISO). "ISO 9001:2015 Quality management systems — Requirements." (Standard for quality management systems).

- Automotive Industry Action Group (AIAG). "IATF 16949:2016 Quality management system standard for the automotive industry." (Automotive sector-specific quality standard).

- Hydraulic Institute (HI). "ANSI/HI Standards for Centrifugal Pumps." (Industry standards for pump testing and performance).

- Institution of Mechanical Engineers (IMechE). "Advances in Engine and Vehicle Thermal Management." (Journal articles discussing efficiency gains from electric cooling systems).

-

Materials Used in Manufacturing Cap End Pipe FittingsNachrichtNov.24,2025

-

Material Properties of CF8M CastingNachrichtNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNachrichtNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNachrichtNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNachrichtNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNachrichtNov.21,2025