Handy, Mobiltelefon:+86-311-808-126-83

Email:info@ydcastings.com

Green Sand vs. Aluminum Die Casting: A Sustainable Choice

The metal casting industry relies on various methods to produce high-quality components, with green sand metal casting and aluminum die casting being two of the most widely used techniques. While Edelstahlguss remains a staple for durable and corrosion-resistant parts, manufacturers are increasingly evaluating sustainability and efficiency. This article explores whether green sand metal casting or aluminum die casting offers a more sustainable alternative for Edelstahlguss applications, considering factors like energy consumption, material waste, and environmental impact.

When it comes to aluminum die casting, several key advantages make it a compelling option for manufacturers seeking a sustainable alternative to stainless steel casting. First, aluminum die casting is a highly efficient process, allowing for the rapid production of intricate components with minimal waste. The use of molds and high-pressure injection ensures that the molten aluminum fills the mold cavity completely, minimizing porosity and defects. This precision reduces the need for secondary machining and finishing, further lowering material waste and energy consumption.

Moreover, aluminum itself is a relatively lightweight material compared to stainless steel, which translates to reduced fuel consumption and lower greenhouse gas emissions during transportation. Additionally, aluminum is highly recyclable, with significant energy savings associated with recycling aluminum scrap compared to producing virgin aluminum from raw materials. This circular economy aspect further enhances the sustainability profile of aluminum die casting.

Understanding Green Sand Metal Casting

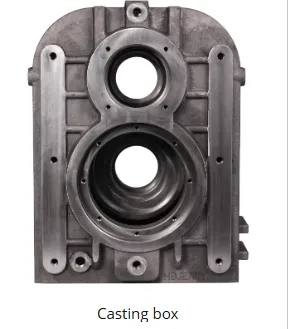

Green sand metal casting is a traditional method that uses a mixture of sand, clay, and water to create molds. It is cost-effective and versatile, making it ideal for complex Edelstahlguss projects.

- Eco-Friendliness:Unlike synthetic binders, green sand metal castinguses natural materials, reducing chemical waste.

- Flexibilität: Suitable for both small and large-scale production, accommodating intricate Edelstahlgussdesigns.

- Energy Efficiency: Requires less energy than high-pressure aluminum die casting, lowering carbon emissions.

Advantages of Aluminum Die Casting

Aluminum die casting is a high-speed, precision-based process that injects molten aluminum into steel molds. It is often compared to Edelstahlguss for lightweight, high-strength applications.

- High Precision: Aluminum die castingproduces tight-tolerance parts, reducing post-machining needs.

- Recyclability:Aluminum is highly recyclable, making aluminum die castinga sustainable choice.

- Production Speed: Faster cycle times than green sand metal casting, ideal for mass production.

Comparing Sustainability Factors Aluminum Die Casting

When evaluating green sand metal casting and aluminum die casting for Edelstahlguss alternatives, sustainability plays a key role.

- Material Waste:Green sand metal castinggenerates reusable sand, while aluminum die casting minimizes scrap through precision.

- Energy Use: Aluminum die castingdemands high energy for melting, whereas green sand metal castingoperates at lower temperatures.

- Longevity: Edelstahlgussoffers superior durability, but aluminum die castingprovides a lighter, corrosion-resistant option.

Industrial Applications and Suitability Aluminum Die Casting

Beide green sand metal casting and aluminum die casting serve different industrial needs, often overlapping with Edelstahlguss applications.

- Automotive:Aluminum die castingdominates for lightweight parts, while green sand metal casting is used for engine blocks.

- Aerospace:Edelstahlgussis preferred for high-strength components, but aluminum die casting reduces weight.

- Construction:Green sand metal castingsupports large structural parts, whereas aluminum die casting aids in fittings and fixtures.

FAQ: Key Questions Answered Aluminum Die Casting

What is the main difference between green sand and aluminum die casting?

Green sand metal casting uses sand molds for versatile shapes, while aluminum die casting relies on metal molds for high precision.

Which method is more cost-effective for stainless steel alternatives?

Green sand metal casting is cheaper for low-volume production, whereas aluminum die casting is cost-efficient for large batches.

Can aluminum die casting replace stainless steel casting?

For lightweight applications, yes. However, Edelstahlguss remains superior for extreme durability and corrosion resistance.

Is green sand casting environmentally friendly?

Yes, green sand metal casting uses natural, reusable materials, reducing waste compared to synthetic alternatives.

Which industries benefit most from aluminum die casting?

Automotive, electronics, and consumer goods industries favor aluminum die casting for its lightweight and high-speed production.

By analyzing these factors, manufacturers can determine whether green sand metal casting or aluminum die casting is the more sustainable choice for Edelstahlguss alternatives. Each method has distinct advantages, making them suitable for different applications within the metalworking industry.

For aluminum die casting, several key benefits stand out. Firstly, it offers exceptional precision and repeatability, ensuring that components are produced to tight tolerances. This is particularly advantageous in industries where high accuracy is critical, such as aerospace and automotive manufacturing. Additionally, aluminum die casting provides a high level of dimensional stability, which means that parts maintain their shape and size over time, even under varying conditions. This stability is essential for functional and aesthetic integrity in end-use products.

-

Materials Used in Manufacturing Cap End Pipe FittingsNachrichtNov.24,2025

-

Material Properties of CF8M CastingNachrichtNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNachrichtNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNachrichtNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNachrichtNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNachrichtNov.21,2025