Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Jan . 19, 2025 03:28

Back to list

cap for pipe end

In the realm of industrial components and piping systems, few elements are as crucial yet understated as the pipe cap. Specifically, when dealing with pipe systems measured in inches or millimeters, such as the keyword 1 4 pipe cap, understanding its functions, uses, and specifications can significantly enhance the reliability and efficiency of a piping system. This article delves into the multifaceted features of pipe caps, focusing on the 1 4 size, and provides insights from both industry experts and seasoned engineers.

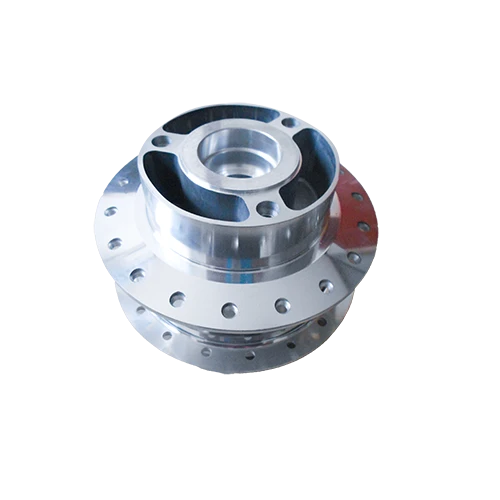

Beyond their primary sealing function, 1 4 pipe caps can also be used for temporary closures during maintenance periods. In such scenarios, their ease of use and removal becomes highly beneficial, especially in complex systems where downtime must be minimized. Jim Harper, an industrial maintenance supervisor, highlights, The adaptability of these pipe caps, particularly in repair settings, adds a layer of operational flexibility, which is invaluable in dynamic industrial environments. In the ever-evolving landscape of industrial piping, the technological advancements are not just limited to the pipes themselves but extend to accessories like pipe caps. Modern manufacturing techniques have allowed for the production of pipe caps with enhanced precision and strength. For example, 3D printing and CNC machining enable the creation of custom-designed caps that fit more seamlessly into unique piping arrangements. Trustworthiness and authority in the context of pipe caps come from adherence to international standards. ISO and ASTM specifications ensure that pipe caps, including the 1 4 variants, meet global benchmarks for quality and suitability. By opting for products that comply with these standards, companies can guarantee not only safety and performance but also maintain compliance with health and environmental regulations. In conclusion, the role of a 1 4 pipe cap in a piping system extends beyond mere closure or termination. It embodies the critical interface of functionality, safety, and efficiency within an industrial context. As industries continue to advance, the evolution of pipe caps will likely see further innovations aimed at improving durability, reducing costs, and enhancing environmental sustainability. For those involved in the specification and installation of piping systems, staying informed about these developments, and selecting components with a proven track record of performance, remains a cornerstone of successful system design and operation.

Beyond their primary sealing function, 1 4 pipe caps can also be used for temporary closures during maintenance periods. In such scenarios, their ease of use and removal becomes highly beneficial, especially in complex systems where downtime must be minimized. Jim Harper, an industrial maintenance supervisor, highlights, The adaptability of these pipe caps, particularly in repair settings, adds a layer of operational flexibility, which is invaluable in dynamic industrial environments. In the ever-evolving landscape of industrial piping, the technological advancements are not just limited to the pipes themselves but extend to accessories like pipe caps. Modern manufacturing techniques have allowed for the production of pipe caps with enhanced precision and strength. For example, 3D printing and CNC machining enable the creation of custom-designed caps that fit more seamlessly into unique piping arrangements. Trustworthiness and authority in the context of pipe caps come from adherence to international standards. ISO and ASTM specifications ensure that pipe caps, including the 1 4 variants, meet global benchmarks for quality and suitability. By opting for products that comply with these standards, companies can guarantee not only safety and performance but also maintain compliance with health and environmental regulations. In conclusion, the role of a 1 4 pipe cap in a piping system extends beyond mere closure or termination. It embodies the critical interface of functionality, safety, and efficiency within an industrial context. As industries continue to advance, the evolution of pipe caps will likely see further innovations aimed at improving durability, reducing costs, and enhancing environmental sustainability. For those involved in the specification and installation of piping systems, staying informed about these developments, and selecting components with a proven track record of performance, remains a cornerstone of successful system design and operation.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS