Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

what is die casting

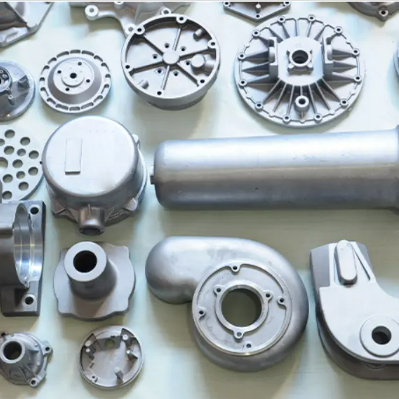

What is Die Casting?

Die casting is a manufacturing process that involves the production of metal parts by forcing molten metal under high pressure into a mold cavity. This technique is widely used for various metals, including aluminum, zinc, and magnesium, due to its ability to produce complex shapes with excellent dimensional accuracy and a smooth surface finish. In this article, we will explore the principles, advantages, applications, and challenges associated with die casting.

Principles of Die Casting

The die casting process begins with the preparation of the die, which consists of two halves that form the mold. The die is typically made of hardened steel, allowing it to withstand the high pressures and temperatures involved in the casting process. Once the die is ready, molten metal is injected into it at high speed, filling the cavity and taking the shape of the mold. The process occurs quickly, often within seconds, allowing for rapid production cycles.

After the metal has cooled and solidified, the die halves are opened, and the finished part is ejected. This speed and efficiency make die casting a popular choice for high-volume production.

Advantages of Die Casting

One of the primary advantages of die casting is its ability to produce intricate designs and precise dimensions. The process allows for complex geometries, which can be challenging to achieve with other manufacturing methods. Additionally, die-cast parts often exhibit superior mechanical properties due to the high pressure under which they are formed, resulting in stronger and more durable components.

Die casting is also cost-effective for large production runs. While the initial costs for creating the die can be high, the rapid production speeds and reduced material waste lead to lower costs per unit over time. Furthermore, die casting can produce parts that require minimal post-processing, such as machining or finishing, which further enhances its cost-effectiveness.

what is die casting

Applications of Die Casting

Die casting is utilized across various industries, including automotive, aerospace, consumer electronics, and industrial machinery. In the automotive sector, die casting is commonly used to manufacture components such as engine blocks, transmission housings, and brackets. The aerospace industry benefits from die casting for producing lightweight and durable parts that contribute to fuel efficiency.

In consumer electronics, die-cast components are often used in housings and structural elements, providing both aesthetics and protection for sensitive electronics. Moreover, the industrial sector utilizes die casting for equipment and machinery parts that require high strength and reliability.

Challenges of Die Casting

Despite its many advantages, die casting does come with certain challenges. The initial investment for creating a die can be significant, which may not be justifiable for low-volume production. Additionally, the process is limited to specific metals and alloys, primarily those that can be melted and injected effectively.

Moreover, maintaining a consistent quality is crucial in die casting. Variations in temperature, pressure, and the quality of raw materials can lead to defects such as porosity, which affects the integrity of the finished product. Therefore, quality control measures are essential to ensure reliability and performance.

Conclusion

In summary, die casting is a sophisticated manufacturing process that offers numerous benefits, including high precision, rapid production cycles, and the ability to create complex shapes. Its widespread applications across various industries underline its importance in modern manufacturing. Despite the challenges it presents, advancements in technology and materials are continually improving the die casting process, ensuring its relevance in the future of industrial production.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025