Mobile:+86-311-808-126-83

Email:info@ydcastings.com

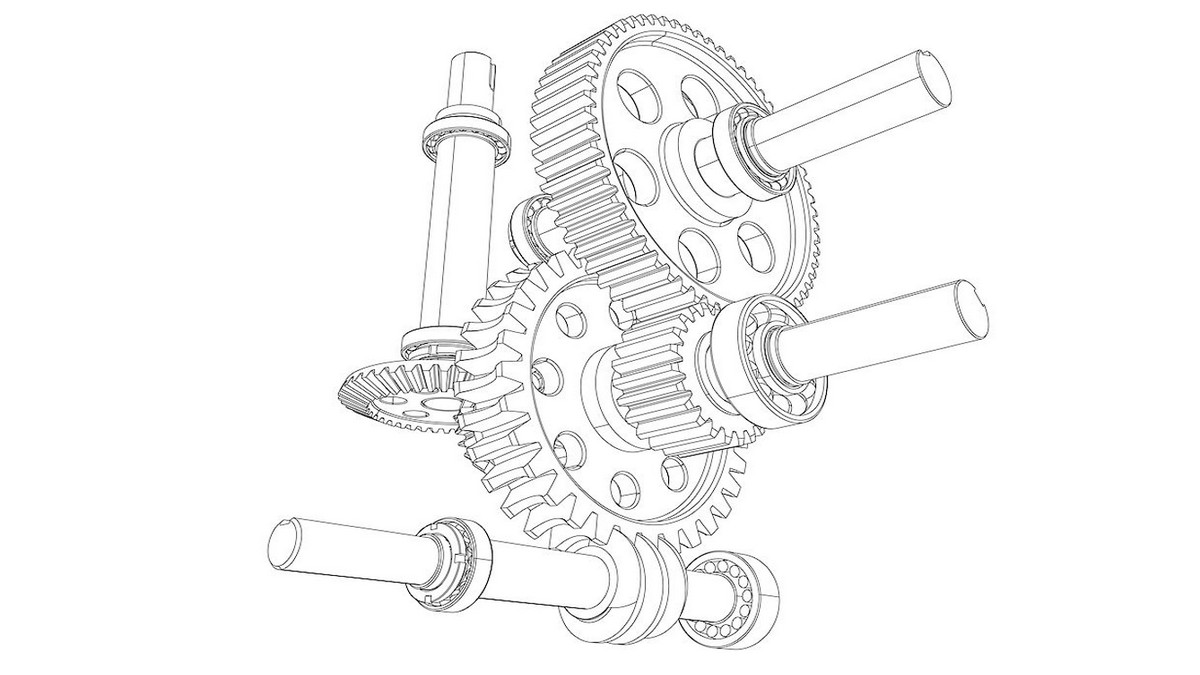

Gearbox What Is a Gearbox? Its Function and Category?

What Is Gear?

Gears are one of the most used mechanical components and are widely used in mechanical transmissions. From small gears for clocks to large gears for ship turbines, it can reliably transmit power.

The Function of the Gear:By selecting a combination of different numbers of teeth, an arbitrary and correct speed ratio can be obtained. Using the increase or decrease of the number of gear combinations, the position of the mutual relationship between the rotary axes can be freely changed. It can be used for transmission between various axes such as parallel axes, intersecting axes, and staggered axes.

What Is a Gearbox?

The gearbox is a kind of speed change device that realizes the speed change effect through the meshing of large and small gears and has many applications in the speed change of industrial machinery. The large gear is installed on the low-speed shaft in the gearbox, and a small gear is installed on the high-speed shaft. Through the meshing and transmission between the gears, the process of acceleration or deceleration can be completed.

Gearbox Housing

The gearbox bears the force from the wind wheel and the reaction force generated by the gear transmission and must have enough rigidity to withstand the force and torque, prevent deformation, and ensure the transmission quality. The design of the gearbox casing should be carried out by the requirements of the layout arrangement of the power transmission, processing and assembly conditions, and easy inspection and maintenance. With the continuous and rapid development of the gearbox industry, more and more industries and different companies have used gearboxes, and more and more companies have developed and grown in the gearbox industry.

The gearbox is an important mechanical component that is widely used in wind turbines. Its main function is to transmit the power generated by the wind wheel under the action of wind to the generator and make it obtain the corresponding speed. Usually, the rotational speed of the wind rotor is very low, which is far from the rotational speed required by the generator to generate electricity.

According to the modular design principle of the unit structure, the gearbox greatly reduces the types of parts and is suitable for mass production and flexible selection. The spiral bevel gear and helical gear of the reducer are all made of high-quality alloy steel carburizing and quenching, the tooth surface hardness is as high as 60±2hrc, and the tooth surface grinding accuracy is as high as 5-6 grades.

What Does the Gearbox Do?

- Acceleration and deceleration are often referred to as speed change gearboxes.

- Change the transmission direction, such as using two sector gears to transmit the force vertically to the other rotating shaft.

- Change the torque: Under the same power conditions, the faster the gear rotates, the smaller the torque on the shaft, and vice versa.

- Clutch function: The purpose of separating the engine from the load can be achieved by separating the two originally meshed gears. such as brakes, etc.

- Distribute power: For example, one engine can be used to drive multiple slave shafts through the main shaft of the gearbox, to realize the function of one engine driving multiple loads.

What Are the Characteristics of the Gearbox?

- Wide selection of gearbox products

The gearbox usually adopts a general design scheme, but in special cases, the design scheme of the gearbox can be changed according to the needs of the user, and it can be modified into an industry-specific gearbox. In the design scheme of the gearbox, the parallel shaft, vertical shaft, general box, and various parts can be changed according to user requirements. - The execution of the gearbox is stable

The execution of the gearbox is stable and reliable, and the transmission power is high. The external box structure of the gearbox can be made of sound-absorbing materials to reduce the noise generated during the working process of the gearbox. The box structure of the gearbox itself and the large fan can effectively reduce the working temperature of the gearbox. In the process of using the gearbox, it is necessary to timely clean the main gearbox. The gearbox cleaning and maintenance machine use the original oil supply and discharge system of the gearbox and the filtered lubricating oil to clean the gearbox without changing any hardware facilities of the gearbox or adding any cleaning agent, which ensures the safe operation of the gearbox. Extends the life of the gearbox. - The gearbox is fully functional

In addition to the deceleration function, the gearbox also has the function of changing the transmission direction and transmission torque. For example, after the gearbox adopts two sector gears, the force can be transmitted vertically to another rotating shaft to realize the change of the transmission direction, while the gearbox changes the principle of transmission torque is that under the same power conditions, the faster the gear rotates, the smaller the torque on the shaft, and vice versa. The gearbox can realize the clutch function during the execution process. If the two originally meshed transmission gears are separated, the connection between the prime mover and the working machine can be cut off to achieve the effect of separating power and load. In addition, the gearbox can complete the power distribution by driving a plurality of driven shafts through one driving shaft.

What Is the Transmission Stage of the Gearbox?

The gearbox is from the input end to the output end, and the gear train formed after a pair of gears meshes is called single-stage gear transmission, and its transmission stage is 1. The gear train formed by two sets of single-stage gear transmission has 2 transmission stages. By analogy, there are 3, 4, and 5 transmission stages. However, when the number of stages increases to a certain number, the reduction of the total equivalent inertia is not obvious. Considering the compact structure, transmission accuracy, and economy, the number of stages should not be too many.

Application Fields of Gearboxes:

Widely used in printing and packaging machinery, three-dimensional garage equipment, environmental protection machinery, conveying equipment, chemical equipment, metallurgical mining equipment, steel power equipment, mixing equipment, road construction machinery, sugar industry, wind power generation, escalator elevator drive, shipbuilding, light industry field, papermaking field, metallurgical industry, sewage treatment, building material industry, hoisting machinery, conveyor line, assembly line, etc. Relevant high power, high-speed ratio, high torque occasions.

What Types of Gears Are There?

According to the gear axis, it is divided into three types: parallel shaft, intersecting shaft, and staggered shaft.

- Parallel shaft gears include spur gears, helical gears, internal gears, racks, helical racks, etc.

- The intersecting shaft gears include straight bevel gears, curved bevel gears, zero-degree bevel gears, etc.

- Staggered shaft gears include staggered shaft helical gears, worm gears, halberd gears, etc.

Types of Industrial Gearboxes:

Common types of automatic transmissions on the market:

- AT gearbox:

Known as a hydraulic automatic transmission, it is the most automatic type of transmission. From the early 4AT gearbox, some cars are equipped with a 9AT gearbox, AT gearbox. The advantages are obvious, the power is more direct, the disadvantages are more prominent, and the fuel consumption is relatively high. - CVT gearbox:

It is called a mechanical continuously variable automatic transmission, which is mainly represented by Japanese cars. Most of the Honda and Nissan models use CVT transmissions. The characteristics of the CVT transmission are obvious. Because the gear ratio is not a discrete point, but a series of continuous values, ride performance is excellent and fuel economy is outstanding, but the disadvantage is relatively obvious, the power momentary. The output has no bursts and is relatively soft. - AMT gearbox:

Abbreviation for Electronically Controlled Mechanical Automatic Transmission, AMT transmission is a compromise between MT transmission and AT transmission. The advantage is that the production cost is lower and it is more convenient to operate than a manual transmission. However, the disadvantages of AMT gearboxes are more prominent. If done incorrectly, it is easy to create a strong sense of frustration, which greatly affects comfort. Also, there are fewer models on the market with AMT transmissions. - Dual-clutch gearbox:

The dual-clutch is the use of two sets of clutches, referred to as DCT. The effect of backlash-free shifting is achieved through the interaction of the two sets of clutches, which are divided into dry dual clutches and wet dual clutches. The dual-clutch gearbox has high-speed shifting, low power loss during shifting, and good fuel economy. The disadvantage of the dual-clutch gearbox is more obvious, the stability of the quality is the main disadvantage of the dual-clutch.

Lubrication Method of Gearbox:

Commonly used gearbox lubrication methods include gear oil lubrication, semi-fluid grease lubrication, and solid lubricant lubrication. For better sealing, high speed, large load, and good sealing performance, gear oil can be used for lubrication. For those with poor sealing performance and low speed, semi-fluid grease can be used for lubrication.

The lubrication system of the gearbox is of great significance to the normal operation of the gearbox. Large-scale wind power gearboxes must be equipped with a reliable forced lubrication system to lubricate the gear meshing area and bearings. Insufficient lubrication accounts for more than half of the reasons for gearbox failure. Lubricant temperature is related to component fatigue and the life of the entire system. - Generally speaking, the maximum oil temperature of the gearbox should not exceed 80℃ during normal operation, and the temperature difference between different bearings should not exceed 15℃. When the oil temperature is higher than 65℃, the cooling system starts to work. When the oil temperature is lower than 10℃, the lubricating oil should be heated to the predetermined temperature before starting.

When the operating temperature of the oil product rises above the set value, the gearbox will be shut down due to high temperature, and the tooth surfaces and bearings will be worn. In addition, the low temperature will also increase the viscosity of the gearbox oil. When the oil pump starts, the load is heavy, and the oil pump motor is overloaded. Gearbox lubricating oil has an optimal temperature range for operation. It is recommended to design a lubricating oil thermal management system for the gearbox lubrication system: when the temperature exceeds a certain value, the cooling system starts to work, and when the temperature is lower than a certain value, the heating system starts to work, and always control the temperature within the optimal range. In addition, improving the quality of lubricating oil is also an important aspect that must be considered in the lubrication system. The lubricant product must have excellent low-temperature fluidity and high-temperature stability.

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025