Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Design and Functionality of Water Pump Casings in Modern Hydraulic Systems

Understanding Water Pump Casings Vital Components for Efficient Operations

Water pumps play a crucial role in a range of applications, from agricultural irrigation systems to municipal water supply networks. At the heart of every water pump is its casing, a critical component that defines the pump's efficiency, durability, and overall performance. In this article, we will explore the importance of water pump casings, their design features, materials used, and considerations for maintenance and selection.

What is a Water Pump Casing?

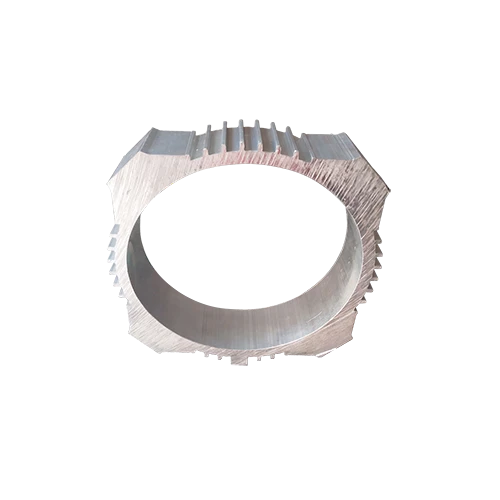

A water pump casing is essentially the outer shell that houses the various components of a water pump, including the impeller, volute, and other structural elements. It serves several key functions it contains the pumped fluid, facilitates the movement of the fluid towards the discharge outlet, and helps protect internal components from external elements.

The design of a water pump casing directly impacts the pump's efficiency and operational smoothness. A well-designed casing minimizes turbulence and hydraulic losses, ensuring that energy is effectively transferred from the motor to the fluid.

Design Features of Water Pump Casings

Water pump casings can vary significantly based on the type of pump and its intended application. However, several design features are commonly observed

1. Shape and Size The shape of the casing impacts flow dynamics. For instance, volute casings, which spiral around the impeller, help to convert kinetic energy into pressure, improving efficiency.

2. Inlet and Outlet Configurations Properly designed inlet and outlet configurations reduce cavitation and maximize flow. Casings may have flanged connections or other fittings to accommodate various piping systems.

3. Reinforcement To withstand the pressure of the pumped fluid, casings are often reinforced. This can include ribbed structures or thicker walls in critical areas.

4. Access Points Some casings include access points for maintenance and repairs, allowing for easier inspection and servicing of internal components.

Materials Used in Water Pump Casings

The material used for a water pump casing is paramount in determining the pump’s longevity and resistance to corrosion. Common materials include

- Cast Iron Known for its strength and durability, cast iron is a popular choice for industrial pumps. It can handle high pressures and is relatively cost-effective.

- Stainless Steel For applications involving corrosive fluids, stainless steel casings are preferred. They offer enhanced resistance to corrosion and wear but at a higher cost.

water pump casing

- Plastic Composites In lighter-duty applications or where chemical resistance is crucial, plastic composites may be used. They are lightweight and can resist a variety of chemicals.

Maintenance and Care

Like any mechanical component, water pump casings require regular maintenance to ensure optimal performance. Key maintenance practices include

1. Visual Inspections Regularly check for signs of wear, corrosion, or leakage. Promptly addressing these issues can prevent major failures.

2. Cleaning Sediment and debris can build up in the casing, affecting performance. Periodic cleaning is essential, especially in environments with high levels of particulate matter.

3. Monitoring Conditions Keeping an eye on operating conditions such as temperature and pressure can help identify potential problems before they escalate.

4. Lubrication For pumps with moving parts integrated into the casing, appropriate lubrication is crucial to reduce friction and wear.

Selecting the Right Water Pump Casing

When selecting a water pump casing, several factors should be considered

- Application Requirements Understanding the specific needs of your application, including flow rate, pressure, and fluid characteristics, will help in choosing the right casing.

- Environmental Factors Conditions such as temperature extremes, exposure to chemicals, and potential physical impacts should dictate the material and design.

- Cost Considerations While it’s important to invest in quality materials, budgetary constraints may influence your choice. Balance long-term performance with upfront costs.

Conclusion

Water pump casings are far more than mere protective shells; they are vital components that directly influence the efficiency and longevity of water pumps. By understanding their design features, materials, and maintenance needs, operators can make informed choices that maximize performance and reliability in their water pumping systems. Whether for agricultural, municipal, or industrial applications, ensuring the right casing is in place is essential for successful water management.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025