Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Jun . 19, 2024 04:08

Back to list

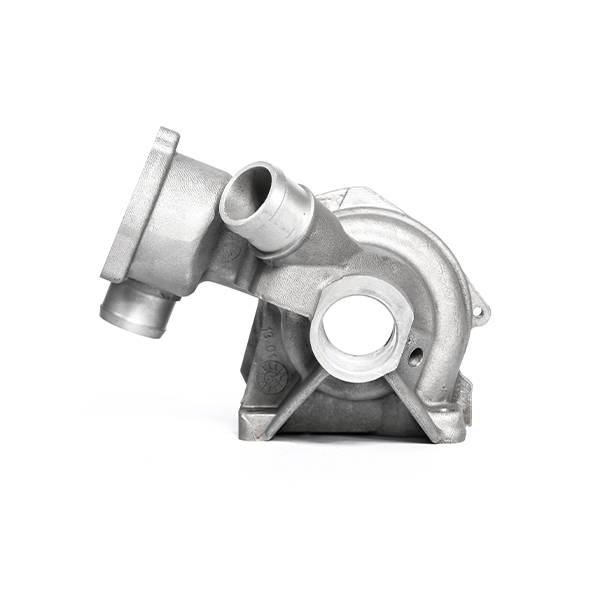

Water pump impeller prices vary by size.

Optimizing Water Pump Impeller Prices

Water pump impellers are crucial components in the world of fluid dynamics and industrial applications. They play a vital role in transferring water from one place to another, whether for agricultural irrigation, municipal water supply, or industrial usage. However, when it comes to purchasing these essential devices, the price factor often becomes a significant consideration. Balancing quality with cost-effectiveness is key to optimizing water pump impeller prices without compromising on performance.

Manufacturers worldwide invest heavily in research and development to create impellers that are not only efficient but also durable and affordable. The materials used can range from aluminum to stainless steel and high-grade plastics, each with its own set of benefits and costs. For instance, while stainless steel impellers may be more expensive initially, their longevity and corrosion resistance make them a cost-effective choice in the long run, especially in applications where the pump is exposed to harsh chemicals or seawater.

On the other hand, advancements in composite materials have led to the creation of impellers that are both lightweight and resistant to corrosion, offering a competitively priced alternative without sacrificing too much in terms of durability. These impellers are particularly suitable for smaller, portable pumps used in agriculture or small-scale industrial settings.

Another factor affecting the price of water pump impellers is the technology integrated into their design

Another factor affecting the price of water pump impellers is the technology integrated into their design Another factor affecting the price of water pump impellers is the technology integrated into their design

Another factor affecting the price of water pump impellers is the technology integrated into their design

Another factor affecting the price of water pump impellers is the technology integrated into their design

Another factor affecting the price of water pump impellers is the technology integrated into their design water pump impeller price. Advanced impeller designs, such as those using computational fluid dynamics (CFD) simulations during the engineering phase, can optimize flow rates and reduce energy consumption. While these technological enhancements might increase the upfront cost, they can lead to significant savings in operational expenses over time.

The market demand also plays a crucial role in pricing. High demand can drive up prices, especially if there is a shortage of raw materials or if certain types of impellers become more popular due to their efficiency in specific applications. Conversely, increased competition among manufacturers can lead to lower prices as companies strive to gain market share by offering more affordable solutions.

In conclusion, the price of water pump impellers is influenced by a multitude of factors including materials, design technology, market demand, and manufacturing competition. As a buyer, understanding these factors can help in making informed decisions that balance the need for an affordable solution with the necessity for reliability and efficiency. By opting for the right impeller at the right price, users can ensure uninterrupted operation and minimize maintenance costs, thereby optimizing their investment in this critical piece of industrial equipment.

water pump impeller price. Advanced impeller designs, such as those using computational fluid dynamics (CFD) simulations during the engineering phase, can optimize flow rates and reduce energy consumption. While these technological enhancements might increase the upfront cost, they can lead to significant savings in operational expenses over time.

The market demand also plays a crucial role in pricing. High demand can drive up prices, especially if there is a shortage of raw materials or if certain types of impellers become more popular due to their efficiency in specific applications. Conversely, increased competition among manufacturers can lead to lower prices as companies strive to gain market share by offering more affordable solutions.

In conclusion, the price of water pump impellers is influenced by a multitude of factors including materials, design technology, market demand, and manufacturing competition. As a buyer, understanding these factors can help in making informed decisions that balance the need for an affordable solution with the necessity for reliability and efficiency. By opting for the right impeller at the right price, users can ensure uninterrupted operation and minimize maintenance costs, thereby optimizing their investment in this critical piece of industrial equipment.

Another factor affecting the price of water pump impellers is the technology integrated into their design

Another factor affecting the price of water pump impellers is the technology integrated into their design

Another factor affecting the price of water pump impellers is the technology integrated into their design

Another factor affecting the price of water pump impellers is the technology integrated into their design water pump impeller price. Advanced impeller designs, such as those using computational fluid dynamics (CFD) simulations during the engineering phase, can optimize flow rates and reduce energy consumption. While these technological enhancements might increase the upfront cost, they can lead to significant savings in operational expenses over time.

The market demand also plays a crucial role in pricing. High demand can drive up prices, especially if there is a shortage of raw materials or if certain types of impellers become more popular due to their efficiency in specific applications. Conversely, increased competition among manufacturers can lead to lower prices as companies strive to gain market share by offering more affordable solutions.

In conclusion, the price of water pump impellers is influenced by a multitude of factors including materials, design technology, market demand, and manufacturing competition. As a buyer, understanding these factors can help in making informed decisions that balance the need for an affordable solution with the necessity for reliability and efficiency. By opting for the right impeller at the right price, users can ensure uninterrupted operation and minimize maintenance costs, thereby optimizing their investment in this critical piece of industrial equipment.

water pump impeller price. Advanced impeller designs, such as those using computational fluid dynamics (CFD) simulations during the engineering phase, can optimize flow rates and reduce energy consumption. While these technological enhancements might increase the upfront cost, they can lead to significant savings in operational expenses over time.

The market demand also plays a crucial role in pricing. High demand can drive up prices, especially if there is a shortage of raw materials or if certain types of impellers become more popular due to their efficiency in specific applications. Conversely, increased competition among manufacturers can lead to lower prices as companies strive to gain market share by offering more affordable solutions.

In conclusion, the price of water pump impellers is influenced by a multitude of factors including materials, design technology, market demand, and manufacturing competition. As a buyer, understanding these factors can help in making informed decisions that balance the need for an affordable solution with the necessity for reliability and efficiency. By opting for the right impeller at the right price, users can ensure uninterrupted operation and minimize maintenance costs, thereby optimizing their investment in this critical piece of industrial equipment. Latest news

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025

Related PRODUCTS