Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Understanding the Functionality and Importance of Valve Bodies in Automotive Systems

Understanding the Valve Body An Essential Component in Fluid Control Systems

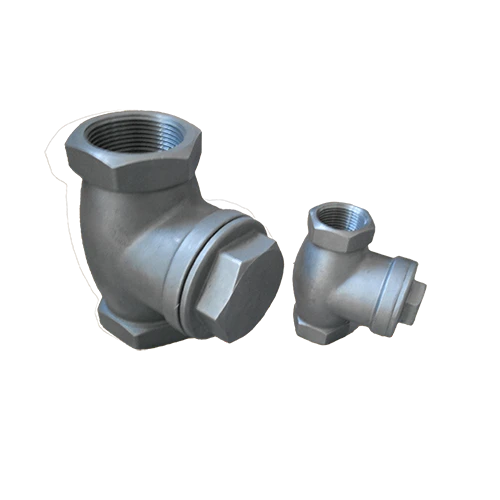

The valve body is a crucial component in various fluid control systems, serving as the housing for internal parts that regulate the flow of liquids and gases. Its design and functionality are integral to numerous applications, from industrial machinery and automotive engines to household plumbing. This article will explore the significance of valve bodies, covering their types, functions, and the materials used in their manufacture.

At the heart of any fluid control system lies the valve body, which provides the structural framework for the valve components. Typically, the valve body includes ports for fluid inlet and outlet, and it houses the mechanisms that open and close the flow path. A well-designed valve body ensures minimal pressure loss and an efficient flow rate, which is essential for the optimal operation of the entire system.

Valve bodies can be classified into several types depending on their intended application and design. The most common types include gate valves, globe valves, ball valves, and butterfly valves. Gate valves allow for fluid flow in a straight line and are often used in applications requiring minimal resistance. Globe valves, on the other hand, are designed for throttling flow and adjusting the rate of fluid passage. Ball valves feature a spherical disc that controls the flow, providing a tight seal and quick operation, making them ideal for applications requiring rapid shut-off. Butterfly valves are characterized by their disk-shaped closure element that rotates to control flow, suitable for large volume applications due to their lightweight and compact design.

valve body

The functionality of a valve body not only depends on its design but also heavily on the materials used in its construction. Valve bodies are commonly made from metals such as stainless steel, brass, and bronze due to their strength and resistance to corrosion. In some cases, plastic materials may be utilized for their lightweight and cost-effective properties, particularly in non-high-pressure applications. Each material offers different advantages and is chosen based on factors like the type of fluid being controlled, temperature range, and pressure conditions.

Moreover, the manufacturing process of valve bodies significantly impacts their performance and longevity. Precision machining and stringent quality control are essential to ensure that the valve body can withstand the stress of operation and provide reliable service. Advances in computer-aided design (CAD) and manufacturing technologies have enabled the creation of more complex and efficient valve bodies, thus enhancing their overall effectiveness in diverse applications.

In conclusion, the valve body plays a pivotal role in fluid control systems across various industries. Understanding the different types of valve bodies, their functions, and the materials used in their construction can help engineers and designers select the most suitable options for their specific applications. As technology advances, it is likely that valve body designs will continue to evolve, leading to even greater efficiencies and innovations in fluid control management. With the right choice and careful consideration, the valve body can ensure the seamless operation of any fluid system, marking its importance in engineering and industrial applications.