Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Impeller Solutions for Enhanced Fluid Dynamics

The Impeller A Critical Component in Fluid Dynamics

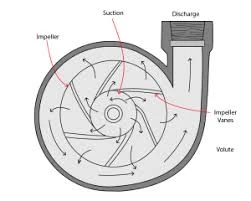

The impeller is a vital component in various mechanical systems, particularly in pumps, turbines, and compressors. It is designed to enhance the movement of fluids by converting rotational energy, often supplied by an electric motor or an engine, into kinetic energy. The significance of the impeller cannot be understated, as it plays a key role in numerous industrial and domestic applications.

At its core, the impeller consists of a rotating disk or drum with blades or vanes that facilitate fluid movement. As the impeller spins, it imparts energy to the fluid, increasing its velocity and allowing it to be transferred efficiently from one location to another. This process is fundamental in multiple systems, such as water treatment facilities, heating, ventilation, and air conditioning (HVAC) units, and even in vehicles where cooling systems rely on impellers to regulate engine temperatures.

One of the primary characteristics of an impeller is its design. Impellers can vary significantly based on the application and the specific requirements of the fluid dynamics involved. Common designs include centrifugal impellers, which draw fluid into the center and expel it outward, and positive displacement impellers, which trap and move a fixed amount of fluid. Each design has its advantages and is chosen based on factors such as required flow rate, pressure, and the nature of the fluid being moved.

the impeller

The materials used to manufacture impellers are equally crucial. They are often made from metals such as stainless steel, bronze, or plastic, depending on the application and the fluid in question. For example, impellers in corrosive environments, such as wastewater treatment, may be constructed from materials resistant to corrosion and wear.

Efficiency is another key factor. An optimized impeller design can significantly reduce energy consumption and operational costs in a system. Engineers often utilize Computational Fluid Dynamics (CFD) software to simulate fluid flow around different impeller designs, allowing for enhanced performance and efficiency.

Moreover, maintenance of the impeller is critical for the longevity and reliability of the entire system. Regular inspections can help detect wear and tear, enabling timely replacements and minimizing downtime.

In conclusion, the impeller is an indispensable component in fluid dynamics, integral to the functionality of many systems that we rely on daily. Understanding its design, materials, and maintenance requirements enhances not only operational efficiency but also the reliability and effectiveness of a wide array of mechanical systems. As technologies advance, the evolution of impeller design continues to play a pivotal role in the future of fluid management solutions.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025