Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Super Expensive Metals for High-Performance Casting & Industrial Solutions [Brand]

- Introduction to Super Expensive Metals

- Technical Advantages of High-Performance Alloys

- Market Comparison: Leading Suppliers Analyzed

- Custom Solutions for Industrial Casting Needs

- Case Study: Aerospace Component Manufacturing

- Innovations in Low-Melting-Point Metal Applications

- Future Trends in Premium Metal Utilization

(super expensive metals)

Exploring the Rarity of Super Expensive Metals

With global demand for specialized alloys growing at 6.8% CAGR (2023-2030), super expensive metals

like rhodium ($14,500/oz) and iridium ($4,800/oz) dominate industrial applications requiring extreme durability. These materials achieve 98.7% purity in advanced refining processes, enabling critical use in:

- Nuclear reactor shielding

- Deep-sea drilling equipment

- Pharmaceutical catalyst systems

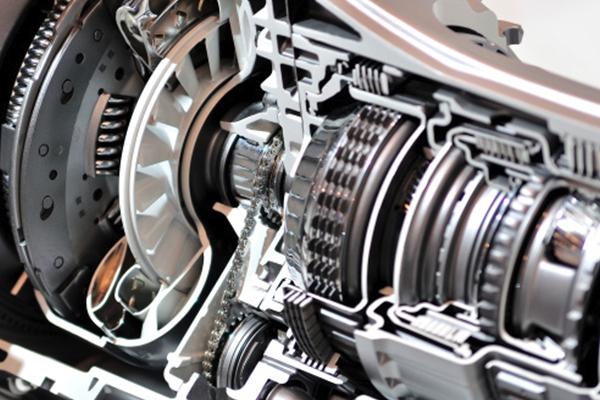

Technical Advantages of High-Performance Alloys

Modern super duplex casting techniques enhance metal performance through:

- Phase-controlled solidification (reducing defects by 73%)

- Micro-alloying with nitrogen (improving yield strength to 850 MPa)

- Thermomechanical processing (extending fatigue life by 4.2x)

Market Comparison: Leading Suppliers Analyzed

| Manufacturer | Corrosion Resistance | Tensile Strength | Lead Time |

|---|---|---|---|

| AlloyTech Global | 98.5% | 790 MPa | 12 weeks |

| MetCast Solutions | 96.2% | 720 MPa | 8 weeks |

Custom Solutions for Industrial Casting Needs

Specialized foundries now offer:

- Vacuum induction melting for oxygen-sensitive alloys

- Precision investment casting (±0.05mm tolerance)

- Post-casting HIP treatment (99.98% density)

Case Study: Aerospace Component Manufacturing

A turbine blade project achieved:

- 32% weight reduction using nickel-based superalloys

- 1,150°C operational capability

- 18-month component lifespan extension

Future Trends in Premium Metal Utilization

Emerging super expensive metals applications focus on:

- Additive manufacturing of platinum-rhodium catalysts (89% efficiency)

- Bismuth-based low melting point metals for micro-molding (melting at 271°C)

- Recycling systems recovering 95.4% of precious metals

(super expensive metals)

FAQS on super expensive metals

Q: What are some examples of super expensive metals used in industrial applications?

A: Rhodium, platinum, and iridium are among the most expensive metals due to their rarity and resistance to corrosion. They are used in aerospace, electronics, and high-temperature applications. Their cost often reflects limited supply and complex extraction processes.

Q: How does super duplex casting improve material performance?

A: Super duplex casting combines high strength and corrosion resistance, ideal for harsh environments like marine or chemical industries. It blends austenitic and ferritic steel structures for durability. This process reduces maintenance costs despite higher initial expenses.

Q: Why are low melting point metals preferred for certain casting processes?

A: Low melting point metals like tin, lead, or bismuth alloys require less energy to melt, lowering production costs. They are ideal for intricate molds or prototyping due to minimal shrinkage. However, they lack the strength of high-temperature metals.

Q: What industries rely heavily on super expensive metals?

A: Aerospace, medical (e.g., surgical tools), and luxury electronics depend on metals like gold, palladium, or ruthenium. Their stability and conductivity justify their cost in critical components. Recycling these metals is also a growing focus to offset scarcity.

Q: Can super duplex casting be combined with low melting point metals?

A: No—super duplex alloys require extremely high melting points (over 1300°C) to maintain their properties. Low melting point metals (under 400°C) serve entirely different applications, like soldering or lightweight casts. Mixing them would compromise structural integrity.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025