Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Jan . 23, 2025 04:52

Back to list

Connector bracket

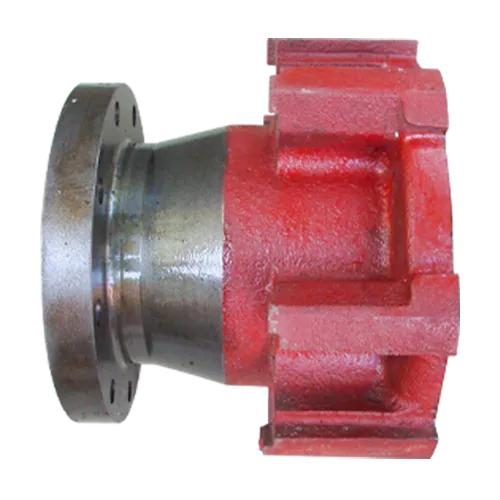

Submersible pump impellers are a critical component in the performance and efficiency of submersible pumps, used predominantly for wastewater, industrial, and agricultural applications. Understanding the different types of impellers and their specific uses can greatly enhance the effectiveness of your pumping system.

While selecting the appropriate impeller type, one must also consider the specific requirements of the application, such as the viscosity of the fluid, the nature and size of the solids, and the desired flow rate. A thorough understanding of these parameters can better guide procurement decisions and result in more efficient and effective operations. To ensure maximum efficiency and longevity of your submersible pump, regular maintenance is pivotal. Professionals recommend inspecting the impeller for wear and damage routinely, as compromised performance often stems from undiagnosed impeller issues. Engaging with expert service providers for routine check-ups can prevent unexpected downtimes and costly repairs. It's also vital to stay updated with the latest advancements and innovations in impeller design and materials. Progressive enhancements in technology offer new materials and design improvements that can revolutionize pump performance. Engineers and industry professionals constantly tend to innovate, so staying informed can offer significant operational advantages. For businesses operating in fluid management sectors, understanding and applying expert knowledge on submersible pump impellers is crucial for maintaining competitive advantage. Utilizing the correct type of impeller not only improves pump efficiency but also proves cost-effective in the long run by minimizing energy consumption and reducing maintenance needs. In conclusion, the diverse designs and functionalities of submersible pump impellers cater to a wide range of applications. Their performance directly impacts the efficiency and durability of the pumping systems, making expertise in impeller selection indispensable for optimizing operations. By combining an understanding of impeller dynamics with regular maintenance practices, businesses can achieve enhanced performance, uphold operational standards, and ensure prolonged service life of their submersible pumps.

While selecting the appropriate impeller type, one must also consider the specific requirements of the application, such as the viscosity of the fluid, the nature and size of the solids, and the desired flow rate. A thorough understanding of these parameters can better guide procurement decisions and result in more efficient and effective operations. To ensure maximum efficiency and longevity of your submersible pump, regular maintenance is pivotal. Professionals recommend inspecting the impeller for wear and damage routinely, as compromised performance often stems from undiagnosed impeller issues. Engaging with expert service providers for routine check-ups can prevent unexpected downtimes and costly repairs. It's also vital to stay updated with the latest advancements and innovations in impeller design and materials. Progressive enhancements in technology offer new materials and design improvements that can revolutionize pump performance. Engineers and industry professionals constantly tend to innovate, so staying informed can offer significant operational advantages. For businesses operating in fluid management sectors, understanding and applying expert knowledge on submersible pump impellers is crucial for maintaining competitive advantage. Utilizing the correct type of impeller not only improves pump efficiency but also proves cost-effective in the long run by minimizing energy consumption and reducing maintenance needs. In conclusion, the diverse designs and functionalities of submersible pump impellers cater to a wide range of applications. Their performance directly impacts the efficiency and durability of the pumping systems, making expertise in impeller selection indispensable for optimizing operations. By combining an understanding of impeller dynamics with regular maintenance practices, businesses can achieve enhanced performance, uphold operational standards, and ensure prolonged service life of their submersible pumps.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS