Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

submersible impeller price

Understanding the Price Dynamics of Submersible Impellers

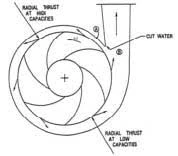

Submersible impellers are integral components in various applications, primarily used in submersible pumps to facilitate fluid movement. These devices play a crucial role in industries such as wastewater management, agriculture, and mining, where effective fluid transport is essential. As industries continue to evolve, the demand for submersible impellers has become increasingly relevant, highlighting the importance of understanding their pricing dynamics.

Understanding the Price Dynamics of Submersible Impellers

Moreover, technological advancements also play a critical role in determining pricing. As manufacturers innovate and develop more efficient designs, there is often a corresponding increase in cost. Advanced submersible impellers may incorporate features such as hydraulic optimization and energy efficiency, leading to increased operational costs. However, these innovations can offer significant long-term savings by reducing energy consumption and increasing the lifespan of the impeller, making them a worthwhile investment for many businesses.

submersible impeller price

Market trends and demand also significantly impact pricing. In periods of economic growth, there is often a surge in construction, agriculture, and related sectors, leading to a higher demand for submersible impellers. This increased demand can drive prices up, especially if supply fails to keep pace. Conversely, during economic downturns or periods of reduced industrial activity, the demand may decrease, leading to price reductions.

Global supply chain factors further complicate pricing dynamics. Fluctuations in the cost of raw materials due to geopolitical issues, tariffs, or natural disasters can lead to increased production costs, which manufacturers may pass on to consumers. Additionally, transportation costs also play a role; rising fuel prices can increase the overall price of delivered goods, including submersible impellers.

Another critical aspect is the level of customization required by clients. Standard submersible impellers may have a set price, but custom-designed impellers that meet specific operational needs or fit unique installation requirements can be significantly more expensive. Tailored designs may involve additional engineering, testing, and manufacturing processes, which contribute to higher costs.

In conclusion, the pricing of submersible impellers is influenced by various interconnected factors including material quality, technological advancements, market demand, global supply chain fluctuations, and customization requirements. For buyers, understanding these dynamics is essential for making informed purchasing decisions. As industries continue to adapt and innovate, staying aware of market trends and technological advancements will help businesses optimize their investments in submersible impellers, ensuring they acquire the best products to meet their specific needs.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025