Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Feb . 17, 2025 11:24

Back to list

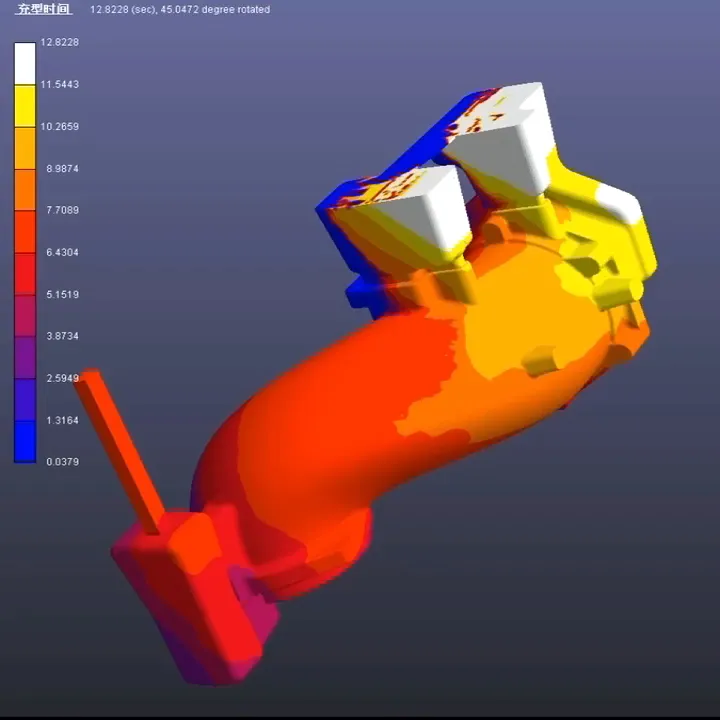

impeller

Straight vane impellers are a fundamental component in various industrial and manufacturing applications, where their design and function play a critical role in achieving efficient fluid movement. These impellers are characterized by their straight, elongated blades, which differentiate them from other types such as the curved vane or backward-curved impellers. They are utilized in a wide range of applications, from simple water pumps to complex chemical processing equipment.

Incorporating engineering expertise, the selection of materials for these impellers is critical. Stainless steel, cast iron, and various alloys are often used due to their resistance to corrosion and wear, which enhances the authority of straight vane impellers in harsh operating environments. This choice of materials aligns with the broader industry trend towards sustainability and resource efficiency, assuring users of the product's trustworthiness in long-term operations. Authoritativeness in the context of straight vane impellers is established by adherence to industry standards and continual product innovation. Leading manufacturers invest in research and development to refine impeller designs, improving performance parameters such as pressure-head and efficiency. They also engage in rigorous testing to ensure compliance with industry regulations, thereby establishing themselves as credible leaders in the fluid handling sector. Moreover, testimonials and case studies from respected organizations using straight vane impellers bolster their trustworthiness. Sharing real-world experiences where these impellers have contributed to operational success, reduced maintenance costs, and improved system reliability provides compelling evidence of their value. Such endorsements lend weight to the choice of straight vane impellers as a preferred solution in demanding applications. In conclusion, the straight vane impeller stands out as a reliable and efficient component in various industrial settings. Its uncomplicated design, coupled with expertise in application and material selection, underscores its practical benefits. The impeller's proven track record in delivering consistent performance under challenging conditions further cements its authority and trustworthiness. As industries continue to evolve, the role of the straight vane impeller remains integral in driving innovations in fluid dynamics and engineering solutions, ensuring they meet the ever-growing demand for efficiency and reliability.

Incorporating engineering expertise, the selection of materials for these impellers is critical. Stainless steel, cast iron, and various alloys are often used due to their resistance to corrosion and wear, which enhances the authority of straight vane impellers in harsh operating environments. This choice of materials aligns with the broader industry trend towards sustainability and resource efficiency, assuring users of the product's trustworthiness in long-term operations. Authoritativeness in the context of straight vane impellers is established by adherence to industry standards and continual product innovation. Leading manufacturers invest in research and development to refine impeller designs, improving performance parameters such as pressure-head and efficiency. They also engage in rigorous testing to ensure compliance with industry regulations, thereby establishing themselves as credible leaders in the fluid handling sector. Moreover, testimonials and case studies from respected organizations using straight vane impellers bolster their trustworthiness. Sharing real-world experiences where these impellers have contributed to operational success, reduced maintenance costs, and improved system reliability provides compelling evidence of their value. Such endorsements lend weight to the choice of straight vane impellers as a preferred solution in demanding applications. In conclusion, the straight vane impeller stands out as a reliable and efficient component in various industrial settings. Its uncomplicated design, coupled with expertise in application and material selection, underscores its practical benefits. The impeller's proven track record in delivering consistent performance under challenging conditions further cements its authority and trustworthiness. As industries continue to evolve, the role of the straight vane impeller remains integral in driving innovations in fluid dynamics and engineering solutions, ensuring they meet the ever-growing demand for efficiency and reliability.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS