Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

stainless steel foundry

The Importance of Stainless Steel Foundries in Modern Manufacturing

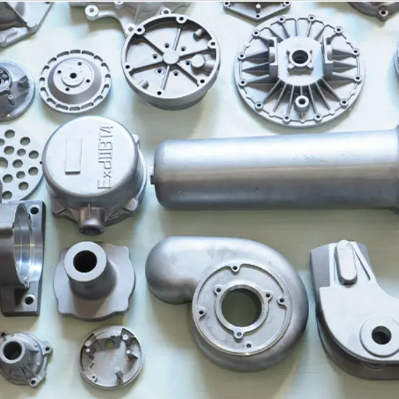

Stainless steel foundries play a crucial role in the manufacturing landscape, contributing significantly to the production of high-quality components used across various industries. These specialized facilities are dedicated to the melting, casting, and processing of stainless steel, a unique alloy known for its resistance to corrosion, durability, and aesthetic appeal.

Stainless steel is composed of various elements, prominently chromium, which provides its outstanding properties. The production process in a stainless steel foundry typically begins with the melting of raw materials in electric arc furnaces or induction furnaces. This environment allows for precise control over the temperature and composition of the molten metal, ensuring that the final product meets stringent quality standards.

The Importance of Stainless Steel Foundries in Modern Manufacturing

Moreover, the demand for stainless steel has surged alongside the growth of construction and infrastructure projects, where it is utilized for structural purposes. Architects and builders favor stainless steel for its combination of strength and aesthetic qualities. From modern skyscrapers to bridges, stainless steel not only enhances visual appeal but also contributes to the longevity and safety of structures.

stainless steel foundry

Sustainability is another critical aspect of stainless steel foundries. Stainless steel is 100% recyclable, and many foundries prioritize eco-friendly practices. By utilizing recycled materials, these facilities reduce the need for virgin resources, minimizing environmental impact. The closed-loop recycling of stainless steel helps conserve energy and lowers overall carbon emissions associated with production.

Quality control is integral to the operations of stainless steel foundries. Advanced testing methods, including metallurgical analysis and stress testing, are employed to ensure that the cast products meet the required specifications. This diligence is particularly important in industries such as aerospace and medical where failures can have catastrophic consequences.

Innovations in technology have also transformed the operations of stainless steel foundries. Computer-aided design (CAD) and simulation software allow foundries to optimize designs and improve efficiency. Automation and robotics have streamlined the production process, resulting in higher outputs and reduced labor costs. These advancements enable foundries to respond promptly to market demands while maintaining high quality.

In conclusion, stainless steel foundries are vital to the manufacturing sector, producing essential components for a variety of applications. Their role in promoting sustainability, ensuring quality, and embracing technological advancements secures their place in a rapidly evolving industrial landscape. As industries continue to grow and diversify, the importance of stainless steel foundries will only increase, solidifying their contribution to the global economy and innovation.