Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

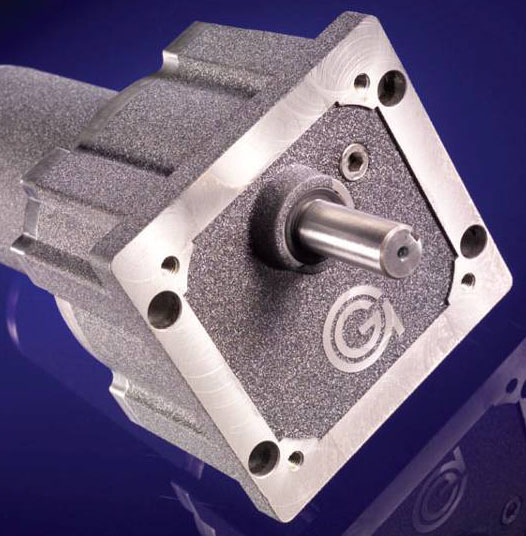

stainless steel angle seat valve

The Advantages and Applications of Stainless Steel Angle Seat Valves

Stainless steel angle seat valves are essential components in various industrial applications, renowned for their durability, reliability, and ability to control the flow of fluids effectively. These valves are designed with an angled seat, which provides a unique construction that enables better flow characteristics and reduces pressure drops. This article explores the structure, benefits, and applications of stainless steel angle seat valves in detail.

Structure and Working Principle

The design of a stainless steel angle seat valve includes a valve body, a seat, and a closure member, typically a disc or a piston, which acts to open and close the flow path. The angle seat configuration allows for a smoother flow transition, significantly minimizing turbulence. When the valve is opened, the fluid flows through the angled seat, which helps in directing the flow with minimal resistance. Conversely, when the valve is closed, the disc or piston forms a tight seal against the seat, preventing any fluid passage.

Manufacturing these valves from stainless steel enhances their overall strength and corrosion resistance. Stainless steel, particularly grades such as 304 and 316, offers excellent performance in harsh environments, making these valves suitable for applications involving corrosive or high-temperature fluids.

Benefits of Stainless Steel Angle Seat Valves

1. Corrosion Resistance One of the prime advantages of stainless steel angle seat valves is their ability to withstand corrosive environments. This characteristic is crucial in industries where aggressive chemicals are used, such as pharmaceuticals, food processing, and petrochemicals.

2. Durability The robust construction of stainless steel valves ensures longevity and requires minimal maintenance. In demanding applications, this durability translates into reduced downtime and lower replacement costs.

stainless steel angle seat valve

3. Effective Flow Control The angled design facilitates better flow control and efficiency. These valves are capable of handling high flow rates while minimizing energy loss, making them ideal for systems requiring precise flow regulation.

4. Versatility Stainless steel angle seat valves can be used in a variety of applications, from water treatment plants to oil refineries. Their adaptability to different industries adds to their appeal as a go-to solution for flow control systems.

5. Safety Features Many stainless steel angle seat valves come equipped with advanced safety features, including fail-safe mechanisms and pressure relief systems, ensuring reliable operation even under extreme conditions.

Applications

Stainless steel angle seat valves find extensive applications across different sectors. In the food and beverage industry, they are used in processes such as brewing and pasteurization, where hygiene and reliability are paramount. Similarly, in the pharmaceutical sector, these valves help manage the flow of critical ingredients during production while ensuring compliance with strict sanitation standards.

In chemical processing, stainless steel angle seat valves effectively control the flow of aggressive chemicals, mitigating the risks associated with leaks and equipment failure. Additionally, in HVAC systems, they serve to regulate hot and cold water flows, contributing to energy efficiency and improved system performance.

Conclusion

In summary, stainless steel angle seat valves offer unique advantages that cater to a wide range of industrial applications. Their corrosion resistance, durability, effective flow control, and versatility make them an excellent choice for various sectors. As industries continue to evolve and demand higher efficiency and safety standards, the importance of reliable components like stainless steel angle seat valves will only grow. Investing in quality valves not only enhances operational efficiency but also contributes to overall system reliability and safety.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025