Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Jun . 21, 2024 14:54

Back to list

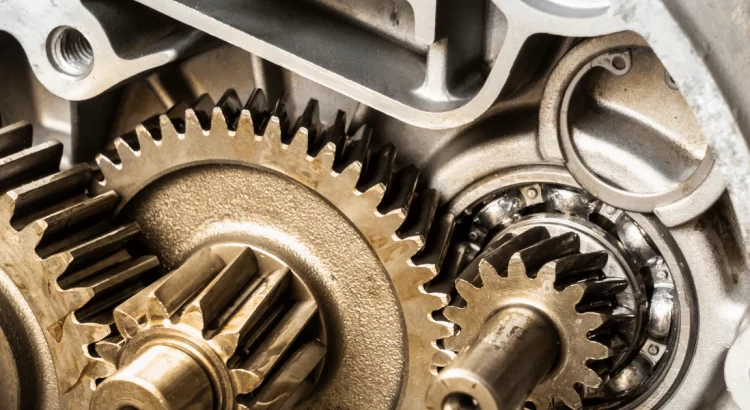

Stainless steel 316 casting process.

The Versatile World of Stainless Steel 316 Casting

Stainless steel 316 casting is a topic that resonates with engineers, architects, and material scientists alike. This particular alloy, also known as AISI 316, boasts an impressive array of properties that make it a preferred choice for numerous applications across various industries.

The chemical composition of stainless steel 316 includes iron, chromium, nickel, and molybdenum, the latter of which sets it apart from other stainless steels. The addition of molybdenum significantly enhances the alloy's corrosion resistance to chloride ions, making it particularly suitable for marine environments and applications involving chemicals or food processing.

The process of casting stainless steel 316 begins with melting the raw materials in a furnace. Once the metal reaches the desired temperature and consistency, it is poured into precision molds crafted to the specifications of the end product. Careful control over cooling rates and subsequent heat treatments ensures that the cast items possess the necessary mechanical and corrosion-resistant properties.

One of the most commendable attributes of stainless steel 316 castings is their ability to maintain structural integrity and aesthetic appeal in extreme conditions. From the rigorous environment of chemical plants to the sophisticated demands of architectural details, these castings provide long-lasting performance and minimal maintenance requirements From the rigorous environment of chemical plants to the sophisticated demands of architectural details, these castings provide long-lasting performance and minimal maintenance requirements From the rigorous environment of chemical plants to the sophisticated demands of architectural details, these castings provide long-lasting performance and minimal maintenance requirements From the rigorous environment of chemical plants to the sophisticated demands of architectural details, these castings provide long-lasting performance and minimal maintenance requirements

From the rigorous environment of chemical plants to the sophisticated demands of architectural details, these castings provide long-lasting performance and minimal maintenance requirements From the rigorous environment of chemical plants to the sophisticated demands of architectural details, these castings provide long-lasting performance and minimal maintenance requirements stainless steel 316 casting.

In the realm of biomedical devices, stainless steel 316 is indispensable due to its excellent biocompatibility and ability to resist germicides and sterilization processes. It is commonly used for surgical instruments, implants, and fixtures where high strength and purity are paramount.

Moreover, the automotive industry finds value in stainless steel 316 for exhaust system components thanks to its resistance to high temperatures and harsh gases. Similarly, the culinary world relies on this alloy for cookware and cutlery that can withstand the wear and tear of daily use while maintaining hygienic standards.

In conclusion, stainless steel 316 casting represents a testament to human ingenuity in material science. Its unique blend of elements provides an exceptional combination of strength, durability, and corrosion resistance, making it an indispensable material in modern industry and daily life. As technology continues to evolve, one can anticipate even more innovative uses for this remarkable alloy, solidifying its place at the forefront of material solutions.

stainless steel 316 casting.

In the realm of biomedical devices, stainless steel 316 is indispensable due to its excellent biocompatibility and ability to resist germicides and sterilization processes. It is commonly used for surgical instruments, implants, and fixtures where high strength and purity are paramount.

Moreover, the automotive industry finds value in stainless steel 316 for exhaust system components thanks to its resistance to high temperatures and harsh gases. Similarly, the culinary world relies on this alloy for cookware and cutlery that can withstand the wear and tear of daily use while maintaining hygienic standards.

In conclusion, stainless steel 316 casting represents a testament to human ingenuity in material science. Its unique blend of elements provides an exceptional combination of strength, durability, and corrosion resistance, making it an indispensable material in modern industry and daily life. As technology continues to evolve, one can anticipate even more innovative uses for this remarkable alloy, solidifying its place at the forefront of material solutions.

From the rigorous environment of chemical plants to the sophisticated demands of architectural details, these castings provide long-lasting performance and minimal maintenance requirements From the rigorous environment of chemical plants to the sophisticated demands of architectural details, these castings provide long-lasting performance and minimal maintenance requirements

From the rigorous environment of chemical plants to the sophisticated demands of architectural details, these castings provide long-lasting performance and minimal maintenance requirements From the rigorous environment of chemical plants to the sophisticated demands of architectural details, these castings provide long-lasting performance and minimal maintenance requirements stainless steel 316 casting.

In the realm of biomedical devices, stainless steel 316 is indispensable due to its excellent biocompatibility and ability to resist germicides and sterilization processes. It is commonly used for surgical instruments, implants, and fixtures where high strength and purity are paramount.

Moreover, the automotive industry finds value in stainless steel 316 for exhaust system components thanks to its resistance to high temperatures and harsh gases. Similarly, the culinary world relies on this alloy for cookware and cutlery that can withstand the wear and tear of daily use while maintaining hygienic standards.

In conclusion, stainless steel 316 casting represents a testament to human ingenuity in material science. Its unique blend of elements provides an exceptional combination of strength, durability, and corrosion resistance, making it an indispensable material in modern industry and daily life. As technology continues to evolve, one can anticipate even more innovative uses for this remarkable alloy, solidifying its place at the forefront of material solutions.

stainless steel 316 casting.

In the realm of biomedical devices, stainless steel 316 is indispensable due to its excellent biocompatibility and ability to resist germicides and sterilization processes. It is commonly used for surgical instruments, implants, and fixtures where high strength and purity are paramount.

Moreover, the automotive industry finds value in stainless steel 316 for exhaust system components thanks to its resistance to high temperatures and harsh gases. Similarly, the culinary world relies on this alloy for cookware and cutlery that can withstand the wear and tear of daily use while maintaining hygienic standards.

In conclusion, stainless steel 316 casting represents a testament to human ingenuity in material science. Its unique blend of elements provides an exceptional combination of strength, durability, and corrosion resistance, making it an indispensable material in modern industry and daily life. As technology continues to evolve, one can anticipate even more innovative uses for this remarkable alloy, solidifying its place at the forefront of material solutions. Latest news

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025

Related PRODUCTS