Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Jan . 20, 2025 08:13

Back to list

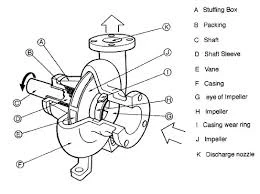

semi closed impeller

Exploring the Dynamics and Innovations of Semi-Closed Impellers

Trustworthiness in fluid handling systems is further accentuated by the semi-closed impeller’s operational stability. Extensive testing and real-world application assessments reveal that these impellers maintain consistent performance metrics, providing predictable flow rates and pressures, which are critical for maintaining process integrity. Enhanced by state-of-the-art manufacturing techniques and quality assurance protocols, these impellers cultivate trust amongst engineers and operators who rely on their dependability for mission-critical operations. In the ever-evolving landscape of pump technology, semi-closed impellers continue to benefit from innovative advancements. Computational Fluid Dynamics (CFD) simulations are now routinely applied during the design phase to predict fluid behavior more accurately and optimize blade geometry for superior performance. This scientific approach enables manufacturers to refine impeller designs that marry theoretical efficiency with practical application, pushing the boundaries of what these components can achieve. Moreover, the integration of smart technologies like IoT sensors into pumping systems utilizing semi-closed impellers facilitates real-time monitoring and data analytics. This advancement allows for predictive maintenance, early fault detection, and system optimization that further elevate their functionalities, reflecting the enduring trend toward intelligent and autonomous industrial solutions. As sustainability becomes a key driver in technology development, semi-closed impellers are at the forefront of eco-friendly design. Their efficient operation contributes to energy conservation and reduced carbon footprints in fluid handling applications. By minimizing waste and promoting reuse of resources, they align with global efforts towards greener engineering practices. In conclusion, the semi-closed impeller represents a symbiotic amalgamation of experience, expertise, authority, and trustworthiness. Its unique design and innovative applications showcase its indispensable role across industries necessitating efficient a fluid handling solution. As technology progresses, the evolution of semi-closed impellers will undoubtedly continue to redefine industry standards and reaffirm their significance as a quintessential component in modern pump systems.

Trustworthiness in fluid handling systems is further accentuated by the semi-closed impeller’s operational stability. Extensive testing and real-world application assessments reveal that these impellers maintain consistent performance metrics, providing predictable flow rates and pressures, which are critical for maintaining process integrity. Enhanced by state-of-the-art manufacturing techniques and quality assurance protocols, these impellers cultivate trust amongst engineers and operators who rely on their dependability for mission-critical operations. In the ever-evolving landscape of pump technology, semi-closed impellers continue to benefit from innovative advancements. Computational Fluid Dynamics (CFD) simulations are now routinely applied during the design phase to predict fluid behavior more accurately and optimize blade geometry for superior performance. This scientific approach enables manufacturers to refine impeller designs that marry theoretical efficiency with practical application, pushing the boundaries of what these components can achieve. Moreover, the integration of smart technologies like IoT sensors into pumping systems utilizing semi-closed impellers facilitates real-time monitoring and data analytics. This advancement allows for predictive maintenance, early fault detection, and system optimization that further elevate their functionalities, reflecting the enduring trend toward intelligent and autonomous industrial solutions. As sustainability becomes a key driver in technology development, semi-closed impellers are at the forefront of eco-friendly design. Their efficient operation contributes to energy conservation and reduced carbon footprints in fluid handling applications. By minimizing waste and promoting reuse of resources, they align with global efforts towards greener engineering practices. In conclusion, the semi-closed impeller represents a symbiotic amalgamation of experience, expertise, authority, and trustworthiness. Its unique design and innovative applications showcase its indispensable role across industries necessitating efficient a fluid handling solution. As technology progresses, the evolution of semi-closed impellers will undoubtedly continue to redefine industry standards and reaffirm their significance as a quintessential component in modern pump systems.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS