Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

sand casting

Sand Casting A Timeless Manufacturing Process

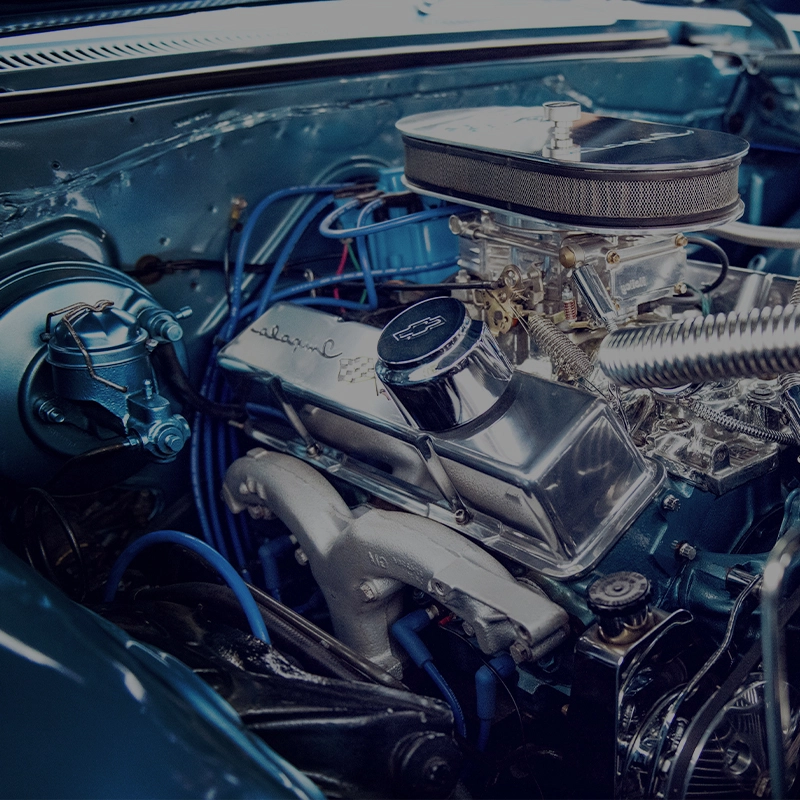

Sand casting, one of the oldest known manufacturing processes, has played an integral role in the production of a wide variety of metal components. This method, which dates back thousands of years, continues to be a preferred choice for manufacturers due to its flexibility, cost-effectiveness, and ability to produce complex geometries.

The fundamental principle of sand casting involves creating a mold from a mixture of sand and a bonding agent, usually clay. The process begins with the formation of a pattern, which mirrors the desired final shape of the casting. This pattern is typically made from materials like wood, metal, or plastic. It is then embedded in sand, which is compacted around it to create a mold. Once the mold is formed, the pattern is removed, leaving a cavity in the shape of the desired object.

After the mold is prepared, molten metal is poured into it. Various metals can be used in sand casting, including aluminum, iron, and magnesium, each offering different properties for the final product. When the metal cools and solidifies, the mold is broken away to reveal the cast part, which may require additional finishing processes to achieve the desired surface quality or dimensions.

sand casting

One of the significant advantages of sand casting is its adaptability

. It can be used to produce both large and small components, from intricate designs for automotive parts to massive components for machinery. Additionally, the sand can be reused for multiple casting cycles, making it an environmentally friendly option.However, sand casting is not without its challenges. The process can be labor-intensive, and achieving a high degree of precision can be difficult. Variations in sand quality, pattern design, and cooling rates can lead to defects such as sand inclusions or dimensional inaccuracies.

Despite these challenges, advancements in technology, including computer-aided design (CAD) and 3D printing, have enhanced the precision and efficiency of sand casting. As a result, it holds a robust position in various industries, including aerospace, automotive, and even artistic applications.

In conclusion, sand casting remains a vital manufacturing process with a rich history. Its ability to produce complex parts economically makes it an enduring choice, and ongoing innovations ensure its relevance in modern manufacturing. As industries continue to evolve, sand casting will undoubtedly adapt, proving that age-old techniques can still have a place in contemporary technology.

-

superior-aluminum-castings-in-automotive-engine-partsNewsAug.22,2025

-

common-materials-used-in-fan-housing-manufacturingNewsAug.22,2025

-

symptoms-of-a-stuck-automobile-water-pump-impellerNewsAug.22,2025

-

the-importance-of-valve-castings-in-water-treatmentNewsAug.22,2025

-

welding-techniques-for-end-cap-stainless-steel-fittingsNewsAug.22,2025

-

how-to-install-a-water-pump-connector-properlyNewsAug.22,2025