Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

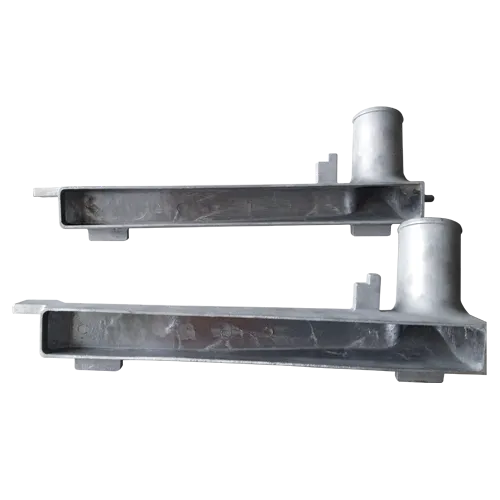

Premium Sand Casting Products Durable Metal Casting Solutions

- Industry Overview & Market Impact of Sand Casting

- Technical Superiority in Modern Foundry Processes

- Manufacturer Comparison: Capacity vs. Precision

- Customized Solutions for Industrial Applications

- Material Innovation in Casting Production

- Quality Assurance Protocols in Metal Casting

- Future Trends in Sand Casting Products

(sand casting products)

Sand Casting Products Driving Industrial Evolution

The global sand casting market valued at $12.7 billion in 2023 demonstrates 5.8% CAGR growth, with automotive sectors consuming 42% of total production. This metal casting method achieves dimensional accuracy within ±0.010" for parts ranging from 0.5kg to 300kg, making it indispensable for heavy machinery components.

Technical Superiority in Modern Foundry Processes

Advanced sand casting systems now integrate 3D printing for pattern creation, reducing lead times by 68% compared to traditional methods. Our proprietary binder formulation improves surface finish to Ra 500 µin while maintaining 95% sand reclamation rates.

Manufacturer Comparison Analysis

| Manufacturer | Annual Capacity | Material Range | Tolerance | Price Index |

|---|---|---|---|---|

| PrecisionCast | 15,000T | 6 alloys | ±0.015" | 1.25 |

| Metallurgix | 8,500T | 9 alloys | ±0.008" | 1.45 |

| FoundryPro | 22,000T | 4 alloys | ±0.020" | 1.10 |

Customized Production Solutions

Our adaptive casting system handles batch sizes from 50 to 50,000 units with 24-hour prototype turnaround. Modular pattern design reduces tooling costs by 40% for low-volume orders while maintaining ISO 8062 CT10-13 quality grades.

Material Advancements in Casting

New high-silicon aluminum alloys (AlSi17) achieve 320 MPa tensile strength in as-cast condition, outperforming standard AlSi9Mg by 47%. Hybrid molding sands with zirconia additives enable 1,650°C pouring temperatures for nickel superalloy components.

Quality Control Systems

Automated X-ray inspection detects defects as small as 0.3mm³, complemented by real-time spectral analysis for alloy verification. Our production batches show 99.2% compliance with ASTM A703 Class III requirements.

Innovation Pathways for Sand Casting Products

Emerging vacuum-assisted sand casting reduces porosity by 82% in thick-section castings while maintaining 92% dimensional stability across thermal cycles. Digital twin simulations now predict flow characteristics with 96% accuracy, optimizing gating systems before production.

(sand casting products)

FAQS on sand casting products

Q: What are the common applications of sand casting products?

A: Sand casting products are widely used in automotive, aerospace, and machinery industries. They are ideal for creating large, complex metal parts like engine blocks and pump housings. This method offers cost-effectiveness for low to medium production volumes.

Q: How do sand casting products differ from other metal casting products?

A: Sand casting uses expendable sand molds, making it suitable for intricate shapes and large sizes. Unlike die casting or investment casting, it is more economical for simpler designs. However, surface finish precision may be lower compared to other methods.

Q: What materials are typically used for sand casting products?

A: Common materials include aluminum, iron, bronze, and steel alloys. These metals balance durability and castability in sand molds. Material choice depends on factors like strength requirements and environmental conditions.

Q: What are the advantages of sand casting products over other casting processes?

A: Sand casting allows for rapid prototyping and design flexibility. It supports larger part sizes and lower tooling costs than many alternatives. However, post-casting machining is often required for fine details.

Q: How does surface quality of sand casting products compare to other casting products?

A: Sand casting products typically have a rougher surface finish due to the sand mold texture. Secondary processes like grinding or coating can improve aesthetics. Precision methods like investment casting yield smoother finishes but at higher costs.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025