Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

pumpe impeller

Understanding Pump Impellers The Heart of Pump Efficiency

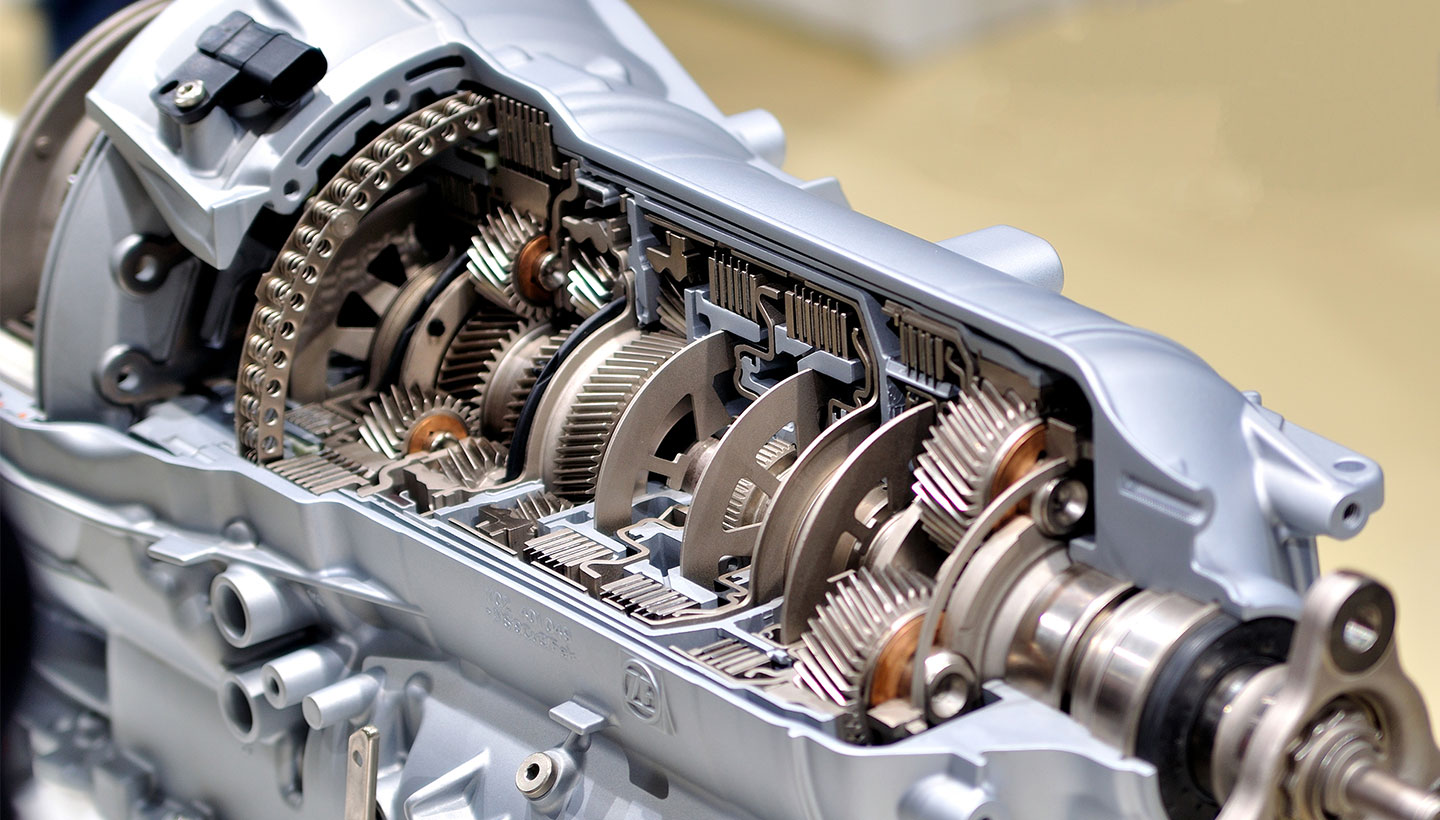

Pumps are indispensable in various industrial applications, from water supply systems to chemical processing, and at the core of these pumps lies a crucial component known as the impeller. The efficiency and effectiveness of a pump largely depend on the design and functionality of its impeller. This article will delve into the significance of pump impellers, their functioning, types, and vital factors influencing their performance.

At its simplest, an impeller is a rotating component within a pump that transfers kinetic energy to the fluid. When the impeller rotates, it imparts motion to the fluid, increasing its velocity and thereby facilitating its movement through the pump system. The design of the impeller is of paramount importance, as it directly affects the pump's performance metrics including flow rate, pressure, and energy consumption.

Types of Impellers

When discussing pump impellers, one can categorize them based on various criteria such as design, application, and the nature of the fluid being handled. The two primary types of impellers are radial flow and axial flow impellers.

1. Radial Flow Impellers These impellers are characterized by blades that are usually curved or flat, extending radially from the center. As the impeller spins, the fluid is pushed outward, creating a high-pressure flow ideal for applications requiring substantial pressure, like in centrifugal pumps. Radial flow impellers are commonly used in water supply systems and wastewater treatment facilities.

2. Axial Flow Impellers In contrast, axial flow impellers are designed to move fluid along the axis of the impeller's rotation. They possess blades that resemble the shape of an aircraft propeller. This type is particularly efficient for applications involving high flow rates and low-pressure differentials, such as in irrigation systems and large-scale water transport.

pumpe impeller

Factors Influencing Performance

The performance of a pump impeller can be significantly influenced by several factors

- Material The choice of materials used in constructing the impeller is crucial. Common materials include stainless steel, bronze, and various plastic compounds. The selection often depends on the fluid being pumped and the operating environment. For instance, corrosive or abrasive fluids may necessitate the use of harder materials to enhance durability and minimize wear.

- Design Specifications The geometry of the impeller, including blade shape and size, plays a pivotal role in determining the efficiency of the pump. Advanced computer-aided design (CAD) tools are often employed to optimize these designs, ensuring maximum flow efficiency while minimizing turbulence and energy loss.

- Operating Conditions The performance of an impeller is also affected by operating conditions such as fluid viscosity, temperature, and pressure. Understanding these parameters helps in selecting the right type of pump and impeller for specific applications.

Conclusion

In conclusion, pump impellers are vital components that significantly impact the performance and efficiency of pumping systems. Their design, material selection, and operational considerations are critical not just for achieving optimal fluid flow, but also for ensuring energy efficiency and cost-effectiveness in various applications. As technology advances, the development of innovative impeller designs continues to enhance pumping solutions, making them more efficient and adaptable to diverse industrial needs. Understanding the fundamental principles of pump impellers thus equips engineers and operators with the knowledge to make informed decisions, ultimately leading to improved operations and outcomes in their respective fields.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025