Introduction to Pump Connector Castings

Connector castings are essential components in pump equipment, serving as critical links between various parts and piping systems. These castings are typically manufactured from robust metal materials such as cast iron, stainless steel, or aluminum alloys, each chosen for its specific properties to meet the demands of industrial applications. The design and material selection of these castings play a pivotal role in determining the performance, stability, and longevity of pumping systems. High-quality connector castings ensure seamless operation, minimize the risk of leaks or mechanical failure, and enhance overall system efficiency. For industries relying on reliable fluid transfer solutions, the importance of precision-engineered connector castings cannot be overstated.

At Hebei Yuanda Trade Co., Ltd., we specialize in delivering superior pump connector castings that meet the rigorous standards of modern manufacturing. Our products are designed to withstand harsh environments while maintaining optimal functionality. This article delves into the technical specifications, advantages, and applications of our connector castings, as well as the company's commitment to innovation and quality.

Technical Specifications of Pump Connector Castings

Understanding the technical specifications of pump connector castings is crucial for selecting the right components for specific applications. The following table summarizes the key parameters of our products:

| Parameter | Details |

|---|---|

| Product Name | Connectors |

| Weight | 5-50 kg |

| Material | GG25-Cast Iron |

| Casting Process | Resin Sand Casting - Cast Iron |

| Shape Accuracy | High precision, ensuring optimal sealing performance |

| Dimensional Accuracy | Minimal size error, critical for installation and functionality |

| Surface Finish | Smooth, free from sand holes or air bubbles |

These specifications highlight the advanced manufacturing processes and materials used to produce our connector castings. The use of resin sand casting ensures high precision and consistency, while the GG25 cast iron material offers excellent mechanical properties, including strength and wear resistance. The high shape and dimensional accuracy of our castings are vital for maintaining the integrity of pump systems, as even minor deviations can lead to leaks or inefficiencies.

Key Features and Advantages of Connector Castings

Our pump connector castings are engineered to deliver exceptional performance in demanding industrial environments. Here are some of the standout features and advantages:

- Corrosion and Wear Resistance: The materials used in our castings are selected for their ability to withstand corrosive substances and abrasive conditions, ensuring long-term durability. This is particularly important in applications involving chemicals, water, or other aggressive media.

- Pressure Resistance: Designed to handle high-pressure environments, our connector castings maintain structural integrity under extreme operating conditions, reducing the risk of failure.

- Smooth Surface Finish: The absence of surface defects such as sand holes or air bubbles minimizes the need for post-casting machining, saving time and costs. A smooth finish also enhances the pump's efficiency and service life.

- Mass Production Capabilities: Advanced production technologies enable efficient mass manufacturing, ensuring consistent quality and cost-effectiveness for large-scale projects.

- Energy Efficiency: By reducing the need for additional processing steps, our casting methods lower energy consumption and labor costs, contributing to sustainable manufacturing practices.

These features make our connector castings an ideal choice for industries such as water treatment, chemical processing, oil and gas, and manufacturing. Whether you're operating a small-scale facility or a large industrial plant, our products are designed to meet your specific needs.

Applications of Pump Connector Castings

Pump connector castings are integral to a wide range of applications where reliable fluid transfer is essential. Some of the key areas where our products are utilized include:

- Water and Wastewater Treatment: In municipal and industrial water systems, our castings ensure efficient pumping of water and sewage, even in corrosive environments.

- Chemical and Petrochemical Industries: The resistance to corrosion and high-pressure capabilities make our castings suitable for handling aggressive chemicals and hydrocarbons.

- Power Generation: In power plants, these castings play a critical role in cooling systems and fuel delivery mechanisms.

- Construction and Mining: The durability of our products ensures reliable performance in harsh conditions, such as those encountered in excavation and material transport.

- Automotive and Aerospace: Precision-engineered castings are used in hydraulic systems and fuel delivery components, where reliability is paramount.

For more information on how our products can enhance your operations, visit our product page.

Company Background: Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. is a leading manufacturer and supplier of high-quality casting solutions, with a strong focus on pump components and industrial machinery. With years of experience in the industry, we have built a reputation for delivering products that meet the highest standards of quality and performance.

Our commitment to innovation and customer satisfaction is reflected in our state-of-the-art production facilities and rigorous quality control processes. We employ advanced technologies such as resin sand casting to ensure precision and consistency in every product. Additionally, our team of experts works closely with clients to understand their unique requirements and provide tailored solutions.

At Hebei Yuanda, we believe that excellence is achieved through continuous improvement. Our products are designed to meet the evolving needs of industries worldwide, and we are dedicated to supporting our customers with reliable, durable, and cost-effective casting solutions.

Why Choose Our Connector Castings?

There are several compelling reasons to choose our connector castings for your industrial applications:

- Superior Quality: Our castings undergo strict quality checks to ensure compliance with international standards, providing peace of mind to our customers.

- Customization Options: We offer tailored solutions to meet the specific requirements of different industries and applications.

- Competitive Pricing: By optimizing our production processes, we are able to provide cost-effective solutions without compromising on quality.

- Global Reach: With a network of distributors and partners worldwide, we ensure timely delivery of our products to customers across the globe.

- Technical Support: Our team provides comprehensive support, from initial design consultations to post-sale assistance, ensuring that our customers achieve optimal results.

For more details about our products and services, visit our company page.

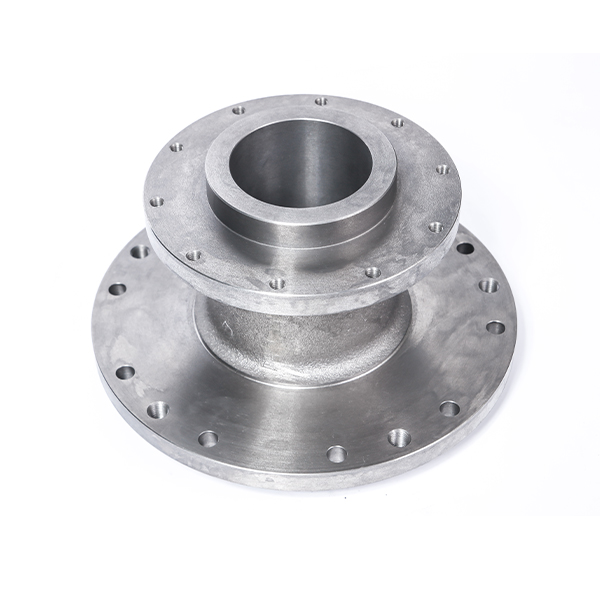

Product Images and Descriptions

Below are the images of our connector castings, showcasing their design and quality:

Industry Standards and Certifications

At Hebei Yuanda Trade Co., Ltd., we adhere to strict industry standards to ensure the quality and reliability of our products. Our connector castings are manufactured in accordance with international standards for material composition, dimensional accuracy, and surface finish. These standards are essential for maintaining consistency and performance across diverse applications.

For further information on our certifications and compliance, please visit our product page.

References and Authority

As highlighted by the National Institute of Standards and Technology (NIST), the importance of precise manufacturing processes cannot be overstated. NIST's research on materials and industrial standards underscores the critical role of high-quality castings in ensuring the reliability and efficiency of mechanical systems. Their work on metrology and quality control provides a framework for evaluating the performance of industrial components, including pump connectors.

NIST emphasizes that "precision in casting processes is essential for achieving the desired mechanical properties and dimensional accuracy in manufactured parts." This aligns with our commitment to delivering products that meet the highest standards of quality and performance.

Reference: National Institute of Standards and Technology (NIST)