Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Pump Connector Castings-Hebei Yuanda Trade Co., Ltd.|Resin Sand Casting,Corrosion Resistance

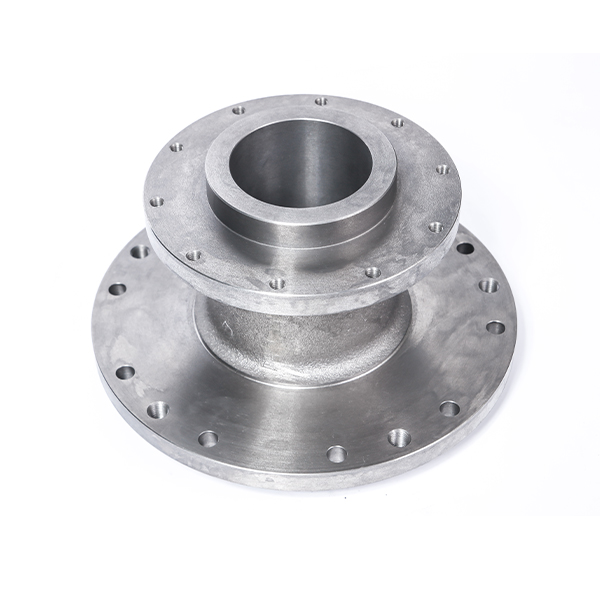

Connector castings play a critical role in the efficient operation of pump equipment, serving as essential components that ensure seamless integration between various parts and piping systems. These castings, typically crafted from materials like cast iron, stainless steel, or aluminum alloys, are engineered to meet the rigorous demands of industrial and commercial applications. Their design and material selection directly impact the performance, stability, and longevity of pumping systems. In this article, we delve into the technical specifications, advantages, and applications of high-quality pump connector castings, while also exploring the expertise of Hebei Yuanda Trade Co., Ltd., a leading provider in this field.

Product Description

Connector castings are integral to pump equipment, facilitating the connection of different components or pipes. These castings are typically manufactured using advanced techniques such as resin sand casting, which ensures high precision and durability. The materials used—cast iron (GG25), stainless steel, or aluminum alloys—are selected based on their ability to withstand corrosion, wear, and high-pressure environments. For instance, cast iron offers excellent strength and thermal stability, making it ideal for heavy-duty applications, while stainless steel provides superior resistance to oxidation and chemical corrosion. Aluminum alloys, on the other hand, are favored for their lightweight properties and ease of machining.

One of the standout features of these connector castings is their shape accuracy. During the casting process, fine molds and advanced equipment are employed to ensure that the final product adheres to precise dimensional requirements. This level of accuracy is crucial for maintaining the sealing performance of the pump, as even minor deviations can lead to leaks or mechanical failures. Additionally, the dimensional accuracy of the castings ensures that they fit seamlessly into the broader system, meeting the exacting standards required for proper installation and operation.

The surface quality of pump castings is another critical factor. High-quality castings are free from defects such as sand holes or air pockets, which can compromise their structural integrity. A smooth surface not only enhances the aesthetic appeal of the product but also reduces the need for subsequent machining or grinding processes, thereby improving production efficiency. Moreover, a well-finished surface contributes to the pump's efficiency and service life, minimizing the risk of premature failure and reducing maintenance costs.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | Connectors |

| Weight | 5-50kg |

| Material | GG25-Cast Iron, Stainless Steel, Aluminum Alloys |

| Casting Process | Resin Sand Casting |

| Surface Finish | Smooth, free from sand holes and air pockets |

| Dimensional Accuracy | High precision, meeting design specifications |

| Corrosion Resistance | Varies by material (e.g., stainless steel offers superior resistance) |

| Pressure Rating | Designed to withstand high-pressure environments |

Key Advantages of High-Quality Connector Castings

Investing in high-quality connector castings offers numerous benefits that directly enhance the performance and reliability of pump systems. One of the primary advantages is their durability. By using materials like stainless steel or aluminum alloys, these castings can withstand harsh environmental conditions, including exposure to moisture, chemicals, and extreme temperatures. This durability ensures that the pump operates efficiently over an extended period, reducing the need for frequent replacements and minimizing downtime.

Another significant advantage is the reduction in leakage risks. The precise shape and dimensional accuracy of the castings ensure a tight seal between connected components, preventing fluid or gas leaks that could lead to system failures. This is particularly important in applications where the pumped material is hazardous or expensive, as even minor leaks can result in costly losses or safety hazards.

Furthermore, the smooth surface finish of these castings contributes to improved efficiency. By minimizing friction and resistance within the pump system, the castings allow for smoother fluid flow, reducing energy consumption and extending the lifespan of the pump. This is especially beneficial in industries where energy efficiency is a key concern, such as water treatment, oil and gas, and chemical processing.

The mass production capabilities of modern casting technologies, such as resin sand casting, also offer cost-effective solutions for manufacturers. By reducing the need for extensive post-casting machining, these methods lower production costs and improve overall efficiency. This makes high-quality connector castings a cost-effective choice for businesses looking to optimize their operations while maintaining high standards of performance.

Applications of Pump Connector Castings

Pump connector castings are utilized across a wide range of industries, each with specific requirements for durability, precision, and performance. In the water treatment sector, these castings are essential for ensuring the reliable operation of pumps used in filtration, distribution, and wastewater management systems. Their corrosion resistance is particularly valuable in environments where exposure to chemicals and moisture is common.

In the oil and gas industry, pump connector castings are critical for transporting crude oil, refined fuels, and other hazardous materials. The ability of these castings to withstand high pressures and extreme temperatures makes them ideal for use in pipelines, storage tanks, and processing equipment. Additionally, their dimensional accuracy ensures compatibility with existing infrastructure, reducing the risk of system failures.

The chemical processing industry also relies heavily on high-quality connector castings. Pumps used in this sector often handle corrosive substances, requiring castings that can resist degradation over time. The stainless steel variants of these castings are particularly well-suited for such applications, offering both corrosion resistance and mechanical strength.

In manufacturing and industrial settings, pump connector castings are used in a variety of systems, including cooling, lubrication, and hydraulic applications. Their smooth surface finish and precision engineering ensure that they can be integrated into complex machinery without compromising performance. This versatility makes them a valuable asset in industries where reliability and efficiency are paramount.

Company Background: Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. is a leading manufacturer and supplier of high-quality pump components, including connector castings. With a commitment to innovation and excellence, the company has established itself as a trusted partner for businesses seeking reliable and durable solutions. Their expertise in resin sand casting and other advanced manufacturing techniques ensures that their products meet the highest standards of quality and performance.

Hebei Yuanda Trade Co., Ltd. offers a wide range of products tailored to the specific needs of various industries. Their connector castings are designed to provide optimal performance in demanding environments, combining durability, precision, and cost-effectiveness. The company's dedication to continuous improvement and customer satisfaction has enabled it to build a strong reputation in the global market.

As a manufacturer, Hebei Yuanda Trade Co., Ltd. adheres to strict quality control measures throughout the production process. This includes rigorous testing of materials, precision machining, and thorough inspection of finished products. By maintaining high standards of quality assurance, the company ensures that its products consistently meet or exceed industry expectations.

The company's commitment to innovation is evident in its adoption of cutting-edge technologies and sustainable practices. By investing in advanced casting techniques and environmentally friendly processes, Hebei Yuanda Trade Co., Ltd. not only enhances the performance of its products but also contributes to the broader goal of reducing the environmental impact of manufacturing.

Conclusion

High-quality pump connector castings are essential components that ensure the efficient and reliable operation of pumping systems. Their precise engineering, durable materials, and advanced manufacturing techniques make them indispensable in industries ranging from water treatment to oil and gas. By choosing products from Hebei Yuanda Trade Co., Ltd., businesses can benefit from superior performance, cost savings, and long-term reliability.

As technology continues to evolve, the demand for high-performance pump components will only grow. Companies like Hebei Yuanda Trade Co., Ltd. are well-positioned to meet this demand by leveraging their expertise in resin sand casting and other advanced manufacturing methods. Their commitment to quality, innovation, and customer satisfaction ensures that their products remain at the forefront of the industry.

For more information about connector castings and other pump components, visit Hebei Yuanda Trade Co., Ltd.'s product page. Explore the company's website to learn more about their comprehensive range of solutions and services.

References

1. National Institute of Standards and Technology (NIST). NIST plays a crucial role in advancing technology through its work on precision measurements, standards, and innovation. Their research and development efforts provide a foundation for industries to improve efficiency, safety, and quality. For more information, visit the NIST website.

Product Images

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025