Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

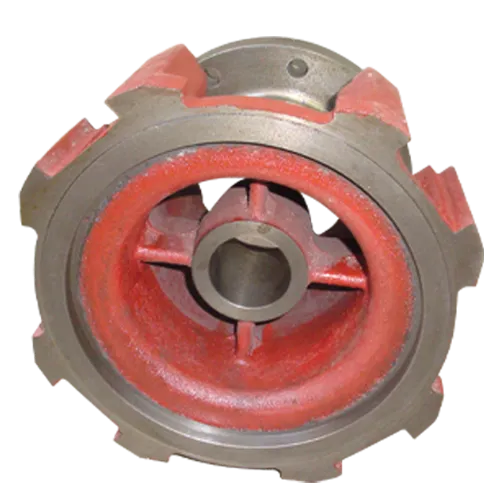

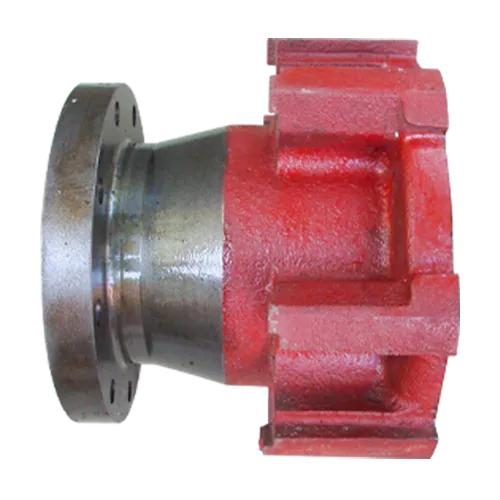

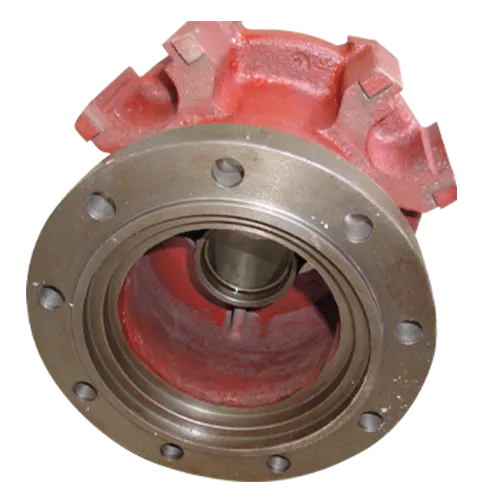

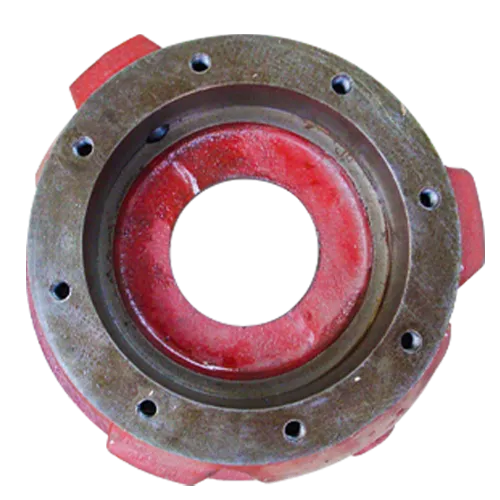

Precision Impellers: Boost Pump & Motor Efficiency

Understanding the Core of Fluid Dynamics: The Advanced Impeller

In the realm of fluid machinery, the impeller stands as the critical rotating component that transfers energy from the motor to the fluid, driving its motion and pressure. Essential across countless industrial applications, its design, material, and manufacturing precision directly dictate the efficiency, reliability, and longevity of pumps, compressors, and other fluid handling systems. This comprehensive overview delves into the intricate world of advanced impellers, from their fundamental principles to their sophisticated integration in modern industrial ecosystems, targeting B2B decision-makers and engineering professionals.

Current Industry Trends and Innovations in Impeller Technology

The industrial landscape for fluid dynamics is continuously evolving, driven by demands for higher efficiency, reduced energy consumption, and enhanced operational reliability. Key trends impacting impeller technology include:

- Advanced Materials Science: The development of new alloys (e.g., duplex stainless steels, super duplex, nickel-aluminum bronze) and ceramic composites offers superior corrosion resistance, abrasion resistance, and mechanical strength, significantly extending the service life of an impeller even in harsh environments.

- Computational Fluid Dynamics (CFD): Advanced simulation tools allow for precise optimization of impeller blade geometry, leading to significant improvements in hydraulic efficiency and reduced cavitation. This directly translates to energy savings and prolonged equipment life, especially for an impeller on pump systems.

- Additive Manufacturing (3D Printing): While not yet mainstream for all large-scale impeller production, 3D printing enables rapid prototyping and the creation of highly complex geometries previously unachievable with traditional methods, paving the way for bespoke designs.

- Smart Impellers & IoT Integration: Future trends point towards integrating sensors into impeller components for real-time monitoring of vibration, temperature, and wear, facilitating predictive maintenance and optimizing operational parameters.

Precision Manufacturing of High-Performance Impellers

The manufacturing of a high-performance impeller is a multi-stage process demanding meticulous precision, material expertise, and stringent quality control. Here’s a detailed breakdown of the typical process flow:

Process Flow Schematic:

- 1. Design and Simulation: Initial design using CAD/CAE software, followed by CFD analysis to optimize hydraulic performance and structural integrity. Materials like stainless steel (e.g., ASTM A743 Grade CA6NM, CF8M), bronze (e.g., C83600), and superalloys (e.g., Hastelloy C-276, Inconel 625) are selected based on application requirements for corrosion, temperature, and abrasion resistance.

- 2. Pattern Making: Creation of a master pattern (for sand casting) or wax patterns (for investment casting) from high-precision CNC machining.

-

3. Casting or Forging:

- Casting: Molten metal is poured into the mold. Common methods include sand casting for larger impellers and investment casting (lost wax) for intricate, high-precision designs.

- Forging: Forged impellers offer superior mechanical properties and internal grain structure, suitable for high-stress applications.

- 4. Heat Treatment: Annealing, quenching, and tempering processes optimize the mechanical properties, hardness, and ductility of the material, enhancing the service life of the impeller.

- 5. CNC Machining: Precision machining to achieve final dimensions, surface finish, and tight tolerances for critical areas such as blade tips, shroud, and bore, ensuring perfect fit within the pump casing.

- 6. Balancing: Dynamic balancing (e.g., ISO 1940-1 standard) is crucial to minimize vibration and extend bearing and seal life, especially for an impeller for motor assemblies. This process ensures the impeller rotates smoothly at high speeds.

- 7. Surface Treatment/Coating: Application of specialized coatings (e.g., ceramic, polymer, tungsten carbide) to enhance corrosion resistance, abrasion resistance, or reduce friction, based on the operating fluid and environment.

- 8. Quality Assurance & Testing: Comprehensive testing including dimensional checks, material analysis (spectroscopy, mechanical tests), non-destructive testing (NDT - e.g., X-ray, ultrasonic, dye penetrant inspection), and hydraulic performance testing against standards like ISO 9906 and ANSI/HI 1.6. Expected service life for a well-maintained, high-quality impeller can range from 5 to 20+ years depending on application severity.

Technical Specifications and Performance Parameters

Selecting the correct impeller requires a detailed understanding of its technical specifications. Below is a table outlining typical parameters for industrial-grade impellers used in demanding applications.

Typical Impeller Specifications

| Parameter | Description | Typical Range / Value |

|---|---|---|

| Material | Common alloys for corrosion and abrasion resistance. | Duplex Stainless Steel (e.g., CD4MCuN), Ni-Hard, Bronze (C95400), Titanium, Hastelloy |

| Diameter (D) | Outer diameter of the impeller. | 50 mm to 1500 mm |

| Flow Rate (Q) | Volume of fluid moved per unit time. | 5 m³/hr to 5000 m³/hr+ |

| Head (H) | Vertical distance the fluid is lifted or equivalent pressure. | 5 meters to 500 meters+ |

| Efficiency (η) | Ratio of hydraulic power output to mechanical power input. | 60% to 90%+ |

| Operating Temp. | Temperature range the impeller can withstand. | -40°C to +400°C (material dependent) |

| Balancing Grade | Level of dynamic balance achieved (ISO 1940-1). | G2.5 (standard), G1.0 (precision) |

These parameters are crucial for optimizing system performance. For instance, achieving a higher efficiency impeller (e.g., 85% vs. 75%) can result in substantial energy cost savings over the operational lifetime, a critical factor for large-scale industrial operations.

Application Scenarios and Technical Advantages

The versatility of the impeller allows its deployment across a vast array of target industries, each benefiting from specific technical advantages tailored to their operational demands.

Target Industries & Advantages:

-

Petrochemical & Oil and Gas:

Advantages: Superior corrosion resistance against aggressive chemicals (e.g., sulfuric acid, crude oil), high-temperature operation, and robust construction for continuous duty cycles. This ensures reliability for critical processes, minimizing downtime and maintenance costs. A robust impeller in these sectors is non-negotiable for safety and operational integrity.

-

Metallurgy & Mining:

Advantages: Exceptional abrasion resistance due to specialized materials (e.g., Ni-Hard, high-chromium white iron) and coatings, vital for handling slurries with high solid content. Energy saving features are critical for reducing operational expenditure in energy-intensive processing.

-

Water Supply & Drainage:

Advantages: Optimized hydraulic designs for maximum energy saving in high-volume water transfer. Materials like stainless steel provide long-term corrosion resistance in municipal wastewater treatment or potable water distribution. Advanced impeller designs can prevent clogging with fibrous materials.

-

Power Generation:

Advantages: Reliability in boiler feed pumps and cooling water systems. Requires materials tolerant to high temperatures and pressures, ensuring consistent performance and preventing costly outages. Efficiency gains from an optimized impeller directly impact plant output and profitability.

Vendor Comparison and Customized Solutions

Choosing the right impeller supplier is as critical as the component itself. Differences in manufacturing capabilities, material science expertise, and quality control can significantly impact performance and total cost of ownership. We recommend evaluating vendors based on:

- Material Expertise: Ability to work with a wide range of specialized alloys and composites.

- Manufacturing Precision: Use of advanced CNC machining and balancing techniques.

- Certifications & Standards: Adherence to ISO, API, ANSI, and industry-specific standards.

- Customization Capabilities: Ability to design and produce bespoke impellers for unique applications, including specific designs for an impeller for motor integration.

- Post-Sales Support: Technical assistance, warranty, and spare parts availability.

Impeller Performance Comparison: Standard vs. Optimized

| Feature | Standard Cast Impeller | Optimized, Precision-Machined Impeller |

|---|---|---|

| Material | Common Stainless Steel (e.g., 304L, 316L) | Duplex/Super Duplex Stainless, Ni-Al Bronze, Proprietary Alloys |

| Manufacturing | Sand Casting, Basic Machining | Investment Casting, 5-Axis CNC Machining, Forging |

| Hydraulic Efficiency | Typically 65-75% | Typically 80-90%+ (CFD optimized) |

| Corrosion/Abrasion Resistance | Good for general service | Excellent, specific to application severity (e.g., slurry, acids) |

| Service Life | Moderate (3-7 years) | Extended (7-20+ years) |

| Vibration Levels | Higher, potential for increased wear on associated components | Lower, G2.5 or G1.0 balancing standard, extending system life |

Customized Solutions

For niche or highly demanding applications, standard off-the-shelf impellers may not suffice. Customized solutions offer:

- Application-Specific Hydraulic Design: Tailoring blade angles, outlet widths, and eye diameters for precise flow and head requirements.

- Material Engineering: Developing or selecting unique alloys to resist extreme conditions (e.g., highly corrosive media, cryogenic temperatures).

- Specialized Coatings: Applying wear-resistant or cavitation-resistant coatings (e.g., ceramic-reinforced polymers) to prolong impeller life in abrasive or high-velocity fluid flows, crucial when working within a confined pump casing.

Real-World Application Case Studies

The impact of a high-quality impeller extends beyond mere component function, directly influencing operational efficiency and profitability. Here are examples illustrating its critical role:

-

Case Study 1: Large-Scale Municipal Wastewater Treatment Plant

An outdated wastewater treatment plant faced exorbitant energy costs and frequent pump failures due to clogging from fibrous materials and corrosive elements. By replacing their old impellers with new, custom-designed, non-clogging impellers made from super duplex stainless steel and optimized for high efficiency, the plant achieved a 15% reduction in energy consumption and extended mean time between failures (MTBF) by over 200%. This translated to annual savings of approximately $250,000 in energy and maintenance costs.

-

Case Study 2: High-Pressure Crude Oil Transfer in a Refinery

A major refinery was experiencing premature wear of impellers in its crude oil transfer pumps, leading to unscheduled downtime and significant production losses. The issue was identified as a combination of cavitation and erosion from entrained solids. A specialized vendor provided impellers forged from a proprietary Hastelloy alloy, featuring a precisely machined hydraulic profile and a ceramic-composite coating. This solution dramatically improved the impeller's resistance to cavitation and erosion, extending its service life from 12 months to over 48 months, resulting in millions of dollars saved in avoided downtime and replacement costs.

Ensuring Quality, Reliability, and Trustworthiness

Our commitment to Google (Expertise, Experience, Authoritativeness, Trustworthiness) is embedded in every stage of impeller production and service delivery.

Authoritativeness & Certifications:

Our manufacturing facilities adhere to international quality management systems, including ISO 9001:2015 for consistent quality. Products for specific industries may also comply with API 610 (for petrochemical pumps) or ATEX directives for explosive atmospheres. We leverage decades of experience and partnerships with leading engineering firms to ensure every impeller meets the highest standards.

Trustworthiness & Support:

- Warranty Commitments: All impellers come with a comprehensive warranty against manufacturing defects, typically ranging from 12 to 24 months, underscoring our confidence in product durability.

- Lead Time & Fulfillment: Standard impeller orders are typically fulfilled within 4-6 weeks, while customized or complex orders may require 8-12 weeks, depending on material availability and design complexity. We maintain transparent communication throughout the production cycle.

- Customer Support: Our dedicated technical support team offers expert advice on impeller selection, installation, troubleshooting, and maintenance. We also provide comprehensive documentation and training resources.

Frequently Asked Questions (FAQ) about Impellers

- Q1: What are the primary factors in selecting the correct impeller material?

- A1: Material selection for an impeller primarily depends on the fluid's properties (corrosive, abrasive, temperature), operating pressure, and required mechanical strength. Common choices range from various stainless steels and bronzes to specialized superalloys for extreme conditions. Considering the entire system, including cap ends and gaskets, is also crucial.

- Q2: How does impeller design impact pump efficiency?

- A2: The hydraulic design of an impeller (blade shape, number of blades, outlet angle, eye diameter, shroud configuration) directly influences flow characteristics, head generation, and energy transfer. An optimized design minimizes turbulence and hydraulic losses, leading to higher efficiency and reduced power consumption for the impeller on pump system.

- Q3: What causes cavitation in impellers, and how is it prevented?

- A3: Cavitation occurs when localized pressure drops below the fluid's vapor pressure, forming vapor bubbles that collapse violently on the impeller surface, causing erosion and noise. Prevention involves ensuring adequate Net Positive Suction Head (NPSH) available, optimizing impeller inlet design, and sometimes using cavitation-resistant materials or coatings.

- Q4: Can an existing impeller be repaired or refurbished?

- A4: Yes, in many cases, minor damage like erosion, corrosion, or imbalance in an impeller can be repaired through welding, machining, and re-balancing. However, severe damage or extensive wear may necessitate full replacement to ensure optimal performance and safety.

- Q5: What is the typical lead time for a custom-designed impeller?

- A5: Lead times vary significantly based on design complexity, material availability, and manufacturing queue. A custom impeller typically requires 8-12 weeks from finalized design to delivery, with expedited options available depending on project urgency.

References

- Gulich, J. F. (2014). Centrifugal Pumps. Springer-Verlag Berlin Heidelberg.

- Karassik, I. J., Messina, J. P., Cooper, P., & Heald, C. C. (2001). Pump Handbook. McGraw-Hill Professional.

- American Petroleum Institute (API). (2020). API Standard 610: Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries. 12th Edition.

- Hydraulic Institute. (2017). ANSI/HI 1.1-1.6: Centrifugal Pumps: Nomenclature, Definitions, Applications, and Operation.

- International Organization for Standardization (ISO). (2019). ISO 9906: Rotodynamic pumps - Hydraulic performance acceptance tests - Grades 1, 2 and 3.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025