Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Feb . 16, 2025 16:40

Back to list

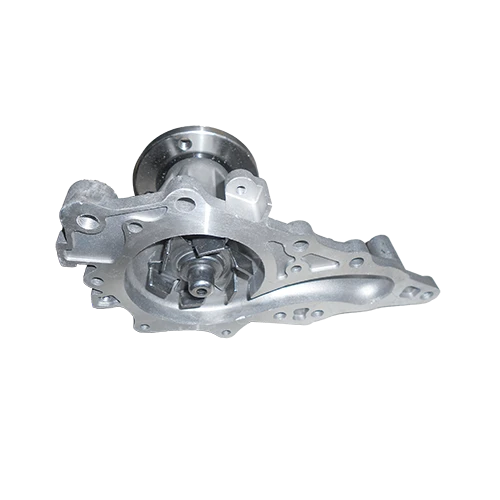

impeller

Oil impellers play a vital role in various machinery, influencing the performance and efficiency of engines and pumps. These components are designed to promote the circulation of oil in systems, ensuring optimal lubrication, cooling, and cleanliness, all crucial elements for the longevity and efficiency of equipment. With an understanding of the functions and significance of oil impellers, industries can benefit enormously from improved machinery performance and reduced maintenance costs.

Trustworthiness in selecting the right oil impeller comes from choosing reputable manufacturers who adhere to high standards of quality control and testing. These manufacturers ensure that their oil impellers are subjected to rigorous testing under various conditions to verify their durability and performance. Moreover, they often provide detailed documentation and support, helping users to select and maintain the right component for their specific application. By choosing trusted brands and maintaining a regime of regular inspection and maintenance, industries can ensure the reliability and efficiency of their machinery. When it comes to the practical application of oil impellers, the right choice depends on the specific requirements of the machinery. Factors like the required flow rate, the type of oil used, temperature conditions, and system pressure must all be considered. Consulting with experts or engineers familiar with oil impeller specifications can offer valuable insights, ensuring that the impeller used is perfectly matched for its intended purpose. Ultimately, the true success of using oil impellers lies in the collaboration between design, engineering, and maintenance teams. Understanding the intricate needs of each machine and tailoring solutions, particularly through customized impeller designs, can enhance operational efficiency. Engineers often employ computational fluid dynamics (CFD) simulations to predict and improve the performance of an impeller, ensuring that every aspect of its operation is optimized for the application it's intended for. Oil impellers, despite their small size, hold enormous potential in optimizing machinery performance. Their proper usage and selection are critical to achieving operational excellence. Through effective design choices, regular maintenance, and collaboration with reputable manufacturers, industries can leverage the full potential of oil impellers, ensuring machinery runs smoothly, efficiently, and with less environmental impact, all while adhering to the highest standards of operational integrity and safety.

Trustworthiness in selecting the right oil impeller comes from choosing reputable manufacturers who adhere to high standards of quality control and testing. These manufacturers ensure that their oil impellers are subjected to rigorous testing under various conditions to verify their durability and performance. Moreover, they often provide detailed documentation and support, helping users to select and maintain the right component for their specific application. By choosing trusted brands and maintaining a regime of regular inspection and maintenance, industries can ensure the reliability and efficiency of their machinery. When it comes to the practical application of oil impellers, the right choice depends on the specific requirements of the machinery. Factors like the required flow rate, the type of oil used, temperature conditions, and system pressure must all be considered. Consulting with experts or engineers familiar with oil impeller specifications can offer valuable insights, ensuring that the impeller used is perfectly matched for its intended purpose. Ultimately, the true success of using oil impellers lies in the collaboration between design, engineering, and maintenance teams. Understanding the intricate needs of each machine and tailoring solutions, particularly through customized impeller designs, can enhance operational efficiency. Engineers often employ computational fluid dynamics (CFD) simulations to predict and improve the performance of an impeller, ensuring that every aspect of its operation is optimized for the application it's intended for. Oil impellers, despite their small size, hold enormous potential in optimizing machinery performance. Their proper usage and selection are critical to achieving operational excellence. Through effective design choices, regular maintenance, and collaboration with reputable manufacturers, industries can leverage the full potential of oil impellers, ensuring machinery runs smoothly, efficiently, and with less environmental impact, all while adhering to the highest standards of operational integrity and safety.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS