Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Need Precision Metal Castings with Fast Lead Times?

metal castings,aluminium metal casting,aluminum casting die,green sand metal casting,aluminium alloy for casting,stainless steel investment casting is a key solution in the manufacturing industry, specifically within Metal smelting and rolling processing industry and casting. This article explores how Welcome To Hebei Yuanda Trade Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- metal castings,aluminium metal casting,aluminum casting die,green sand metal casting,aluminium alloy for casting,stainless steel investment casting Overview

- Benefits & Use Cases of metal castings,aluminium metal casting,aluminum casting die,green sand metal casting,aluminium alloy for casting,stainless steel investment casting in casting

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on metal castings,aluminium metal casting,aluminum casting die,green sand metal casting,aluminium alloy for casting,stainless steel investment casting from Welcome To Hebei Yuanda Trade Co., Ltd.

metal castings,aluminium metal casting,aluminum casting die,green sand metal casting,aluminium alloy for casting,stainless steel investment casting Overview

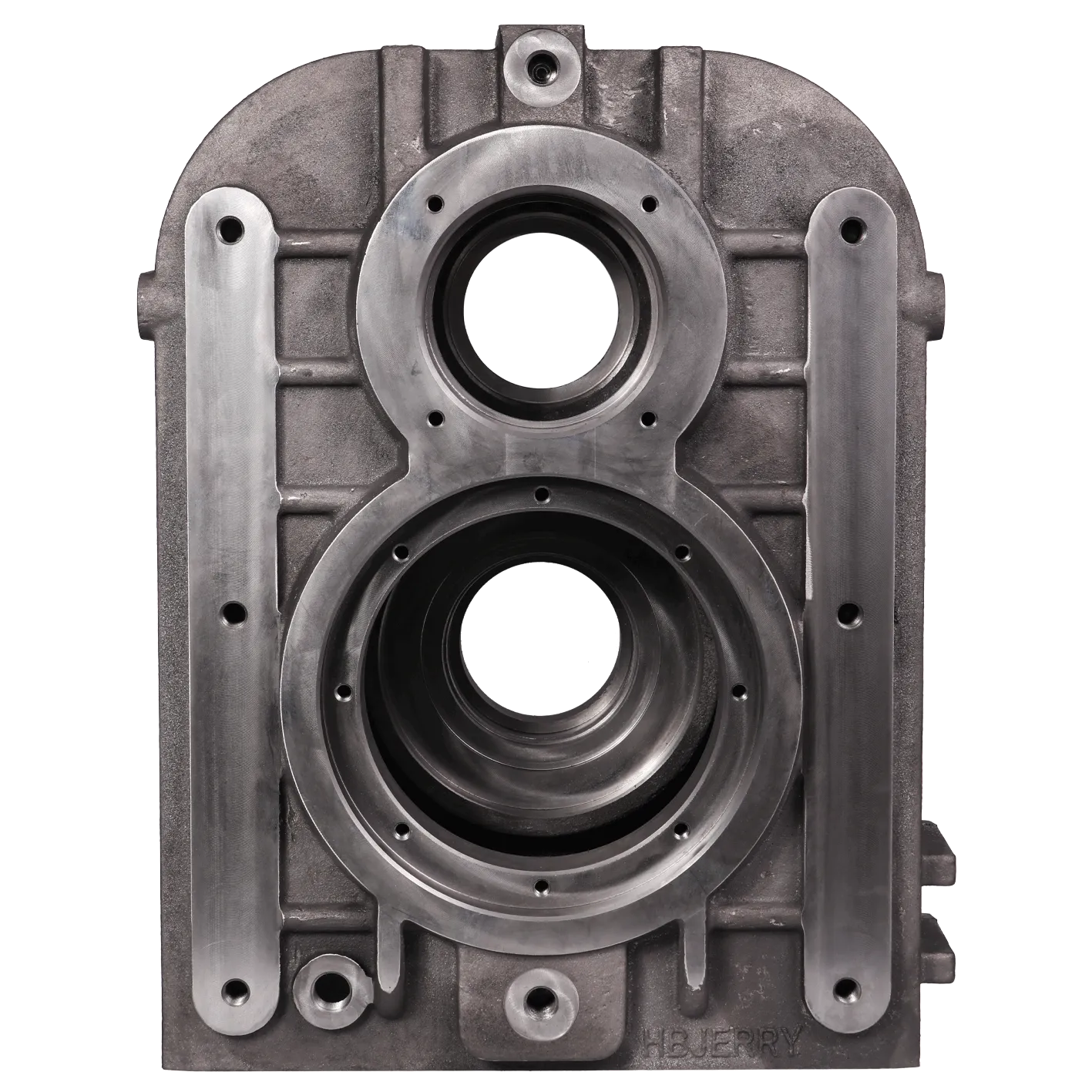

Metal castings remain foundational to precision manufacturing, enabling complex geometries, high repeatability, and scalable production across industries. In practice, aluminium metal casting excels when weight savings and thermal conductivity matter; aluminum casting die (high-pressure die casting with engineered tooling) delivers tight tolerances at volume; green sand metal casting provides cost-effective flexibility for medium-to-large components; and stainless steel investment casting achieves near-net-shape parts with excellent surface finish and corrosion resistance. Selecting the right aluminium alloy for casting (e.g., Al-Si-Mg systems such as A356/A357 or Al-Si-Cu like A380) or stainless grade for investment casting (e.g., 304/316 equivalents) is crucial to balancing strength, machinability, and environmental exposure.

Welcome To Hebei Yuanda Trade Co., Ltd. supports B2B decision makers with process-agnostic guidance and robust production execution. Typical specifications we help customers achieve include consistent dimensional accuracy through disciplined gating/feeding design, optimized aluminum casting dies for cycle-time stability, and investment casting surface finishes that reduce machining time. Whether you require prototype quantities to validate DFM or full-series runs, our team aligns alloy selection and process parameters with your target performance, budget, and timeline.

Benefits & Use Cases of metal castings,aluminium metal casting,aluminum casting die,green sand metal casting,aluminium alloy for casting,stainless steel investment casting in casting

Across casting programs, the right pairing of process and alloy unlocks outsized value. Aluminium metal casting and aluminum casting die are often specified for lightweight housings, EV driveline parts, heat sinks, and automation components—where weight reduction and heat transfer are critical. Green sand metal casting remains the workhorse for pump/valve bodies, gearboxes, counterweights, and structural brackets, offering broad size ranges and excellent cost-to-complexity ratios. Stainless steel investment casting suits food-grade hardware, marine fittings, instrumentation, turbine components, and high-corrosion environments requiring stable mechanical performance and clean surfaces.

Welcome To Hebei Yuanda Trade Co., Ltd. differentiates with early DFM collaboration, robust riser/runner engineering, and thoughtful alloy selection—whether an aluminium alloy for casting is optimized for T6 heat treatment and pressure tightness, or a stainless steel investment casting requires specific ferrite control and passivation outcomes. Customers benefit from tighter tolerance attainment, reduced secondary machining, improved leak-tightness, and repeatable metallurgy. This combination helps shorten validation cycles and delivers dependable PPAP-level documentation to keep launches on schedule.

Cost, Maintenance & User Experience

Total cost of ownership in casting spans tooling, piece price, yield, secondary operations, logistics, and long-term reliability. Aluminum casting die programs typically carry higher upfront tooling but achieve lower part costs at volume through cycle-time efficiency and reduced machining. Green sand metal casting tools are cost-effective for mid-volume and larger parts, while stainless steel investment casting can minimize machining and assembly by consolidating features, often improving lifecycle ROI despite higher unit cost.

Customers in the Metal smelting and rolling processing industry report measurable benefits when process engineering is addressed early—fewer reworks, better dimensional stability, and more predictable lead times. Welcome To Hebei Yuanda Trade Co., Ltd. emphasizes preventative tooling maintenance, stable melt practices, and consistent mold media management to sustain yield. The outcome is improved part-to-part consistency and lower warranty exposure. From first article to steady state, our user experience centers on transparent communication, milestone tracking, and practical cost-down roadmaps that respect quality risk.

Sustainability & Market Trends in manufacturing

Global trends favor near-net-shape manufacturing, lighter weight designs, and material efficiency—areas where metal castings excel. Aluminum programs increasingly leverage recycled streams to cut embodied carbon, while modern green sand metal casting lines reclaim sand to reduce waste. Investment casting further supports sustainability by consolidating features and decreasing material removal during machining. Regulatory drivers and customer ESG goals are accelerating this shift, especially across transportation, energy, and industrial equipment.

Welcome To Hebei Yuanda Trade Co., Ltd. takes a forward-looking approach: advising on alloy choices that balance performance with recyclability, optimizing gating to reduce scrap, and encouraging process routes that minimize secondary operations. We track market movements in EV platforms, high-efficiency motors, automation, and fluid handling—ensuring our solutions anticipate tightening tolerances, corrosion demands, and thermal loads. For B2B leaders, this means resilient supply strategies aligned with both compliance and competitiveness.

Conclusion on metal castings,aluminium metal casting,aluminum casting die,green sand metal casting,aluminium alloy for casting,stainless steel investment casting from Welcome To Hebei Yuanda Trade Co., Ltd.

From lightweight aluminium metal casting to robust green sand metal casting and precision stainless steel investment casting, choosing the optimal process and alloy is decisive for quality, cost, and time-to-market. Welcome To Hebei Yuanda Trade Co., Ltd. combines engineering rigor with responsive service to deliver scalable, high-performance metal castings aligned to your specification and budget.

Contact us: email: info@ydcastings.com

Visit our website: https://www.ydcastings.com

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025