Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Jan . 20, 2025 07:43

Back to list

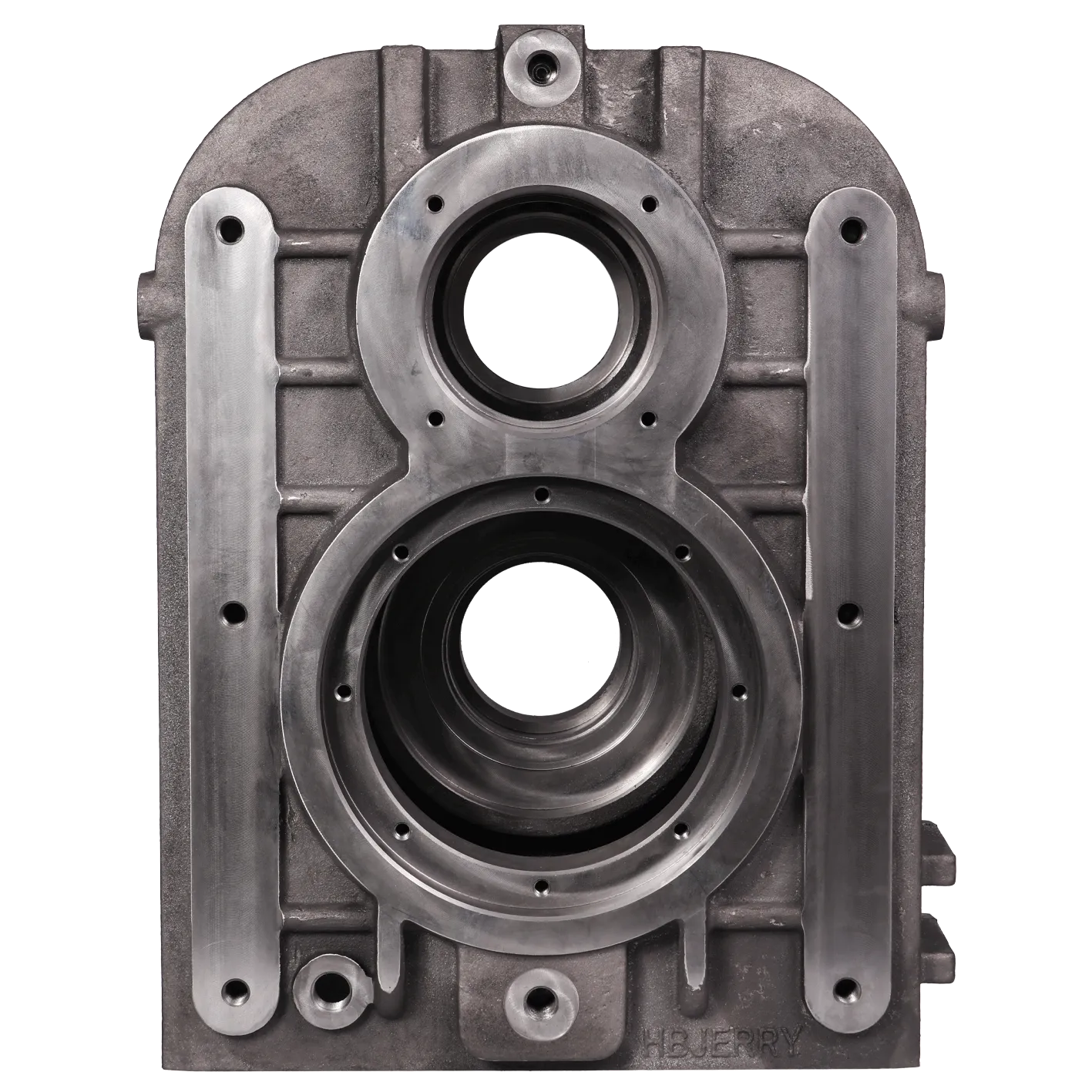

motor pump impeller

The Importance of Motor Pump Impellers in Modern Fluid Dynamics

It's not only essential to choose the right type of impeller and material but also to consider the experience of professionals who install and maintain them. Real-world scenarios often reveal that impeller-related failures commonly stem from poor installation practices or lack of maintenance. Thus, turning to experts who have a track record of success in installing and maintaining these systems can increase operational longevity and reliability. Regular maintenance, which includes checking for wear and tear, ensuring proper alignment, and monitoring performance metrics, plays a critical role. A neglected or improperly maintained impeller can lead to pump inefficiencies, increased energy costs, or catastrophic failures that could disrupt processes and incur significant financial losses. In industries where precision and reliability are crucial, such as chemical processing, water treatment, and food production, the authority of well-engineered and properly maintained motor pump impeller systems cannot be overstated. Trust is built through partnerships with reputable companies that provide detailed documentation, warranties, and comprehensive service options. Emerging technologies are also shaping the future of motor pump impellers. Innovations like 3D-printed impellers allow for rapid prototyping and customization, offering solutions to specific fluid dynamics challenges that traditional manufacturing processes might struggle to address. Smart sensors and the Internet of Things (IoT) are beginning to integrate into pump technology, enabling real-time monitoring of impeller performance and preemptive strategies for maintenance. The expert consensus emphasizes the significance of aligning with experienced manufacturers and suppliers who stand by their products with robust customer support. Investing in quality impellers from trusted sources not only ensures compliance with industry standards but also enhances operational efficiency, provides peace of mind, and ultimately, protects your investment. In conclusion, the intricate design and application requirements of motor pump impellers underline the importance they have in today’s fluid dynamics applications. By focusing on experience, expertise, authority, and trustworthiness, businesses can optimize their use of motor pump impellers, paving the way for improved efficiency and reliability in their operations. Whether it's through meticulous material selection, leveraging cutting-edge technology, or ensuring regular maintenance, the right approach to motor pump impellers is invaluable for success across multiple industries.

It's not only essential to choose the right type of impeller and material but also to consider the experience of professionals who install and maintain them. Real-world scenarios often reveal that impeller-related failures commonly stem from poor installation practices or lack of maintenance. Thus, turning to experts who have a track record of success in installing and maintaining these systems can increase operational longevity and reliability. Regular maintenance, which includes checking for wear and tear, ensuring proper alignment, and monitoring performance metrics, plays a critical role. A neglected or improperly maintained impeller can lead to pump inefficiencies, increased energy costs, or catastrophic failures that could disrupt processes and incur significant financial losses. In industries where precision and reliability are crucial, such as chemical processing, water treatment, and food production, the authority of well-engineered and properly maintained motor pump impeller systems cannot be overstated. Trust is built through partnerships with reputable companies that provide detailed documentation, warranties, and comprehensive service options. Emerging technologies are also shaping the future of motor pump impellers. Innovations like 3D-printed impellers allow for rapid prototyping and customization, offering solutions to specific fluid dynamics challenges that traditional manufacturing processes might struggle to address. Smart sensors and the Internet of Things (IoT) are beginning to integrate into pump technology, enabling real-time monitoring of impeller performance and preemptive strategies for maintenance. The expert consensus emphasizes the significance of aligning with experienced manufacturers and suppliers who stand by their products with robust customer support. Investing in quality impellers from trusted sources not only ensures compliance with industry standards but also enhances operational efficiency, provides peace of mind, and ultimately, protects your investment. In conclusion, the intricate design and application requirements of motor pump impellers underline the importance they have in today’s fluid dynamics applications. By focusing on experience, expertise, authority, and trustworthiness, businesses can optimize their use of motor pump impellers, paving the way for improved efficiency and reliability in their operations. Whether it's through meticulous material selection, leveraging cutting-edge technology, or ensuring regular maintenance, the right approach to motor pump impellers is invaluable for success across multiple industries.

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS