Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Innovative Design for Enhanced Performance of Motorized Impellers in Fluid Systems

The Evolution and Impact of Motorized Impellers in Fluid Dynamics

In the realm of fluid dynamics, the advent and application of motorized impellers have marked a significant turning point in various industries ranging from wastewater treatment to marine engineering. Motorized impellers, defined as devices that enhance fluid motion by means of mechanical propulsion, have transformed conventional practices by offering increased efficiency, enhanced performance, and better operational control. This article delves into the evolution, working principles, applications, and future potential of motorized impellers.

The Evolution of Motorized Impellers

The journey of impeller technology began centuries ago, with rudimentary methods such as wind and water wheels providing primitive forms of propulsion. However, with the industrial revolution and subsequent technological advancements, the design and functionality of impellers underwent a revolutionary transformation. The introduction of electric and hydraulic motors enabled the creation of motorized impellers, which provided a consistent and adjustable source of power for fluid movement.

Motorized impellers have since evolved from simple designs to complex, multi-bladed systems that can be finely tuned to various operational parameters. Today's impellers are crafted from advanced materials such as composites and high-grade polymers, which offer durability and resistance to corrosion and degradation. This evolution has rendered motorized impellers essential components in modern industrial applications.

Working Principles

At the core of motorized impellers is the principle of converting rotational energy into fluid momentum. The impeller, when rotated by an electric or hydraulic motor, generates a pressure differential that propels fluid through a system. The design of the impeller, including factors such as blade shape, angle, and size, plays a crucial role in determining its efficiency and effectiveness.

Motorized impellers can be classified into various types, including centrifugal, axial, and mixed-flow impellers. Centrifugal impellers are primarily used in applications requiring high flow rates and pressure, making them ideal for pumps and HVAC systems. Axial impellers, on the other hand, work well in low-pressure applications, often employed in ventilation systems and marine propulsion. Understanding the nuances of each type is essential for selecting the appropriate motorized impeller for a given application.

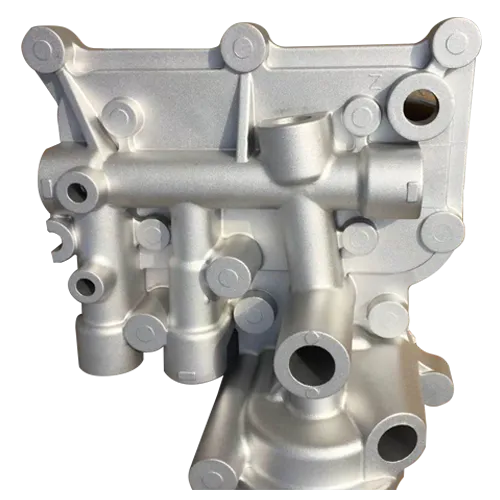

motorized impeller

Applications in Various Industries

The applications of motorized impellers are vast and varied, touching multiple sectors. In wastewater treatment, for example, motorized impellers facilitate the aeration process, providing oxygen to microbes that break down organic waste. In the marine industry, they are critical for propulsion systems in ships and submarines, ensuring efficient movement while minimizing energy consumption.

The chemical industry also benefits from motorized impellers, which are utilized in reaction vessels for mixing and promoting chemical reactions. In HVAC systems, motorized impellers play a vital role in maintaining airflow and temperature control, enhancing comfort and energy efficiency in residential and commercial buildings.

Future Potential

As technology continues to advance, the future of motorized impellers looks promising. Innovations in materials science, control systems, and design will lead to even more efficient and sustainable impeller systems. The integration of smart technologies such as IoT (Internet of Things) is set to enhance monitoring and control capabilities, allowing for real-time adjustments based on operational data.

Furthermore, as industries strive to reduce their carbon footprint, the demand for energy-efficient motorized impellers is expected to grow. This could lead to research focused on developing eco-friendly designs and alternative power sources, further propelling the evolution of motorized impeller technology.

Conclusion

Motorized impellers represent a pivotal innovation in fluid dynamics, enhancing efficiency and expanding the capabilities of various industrial processes. As we continue to explore the potential of this technology, its implications for sustainability and efficiency will likely become more significant. Understanding the evolution, working principles, and applications of motorized impellers is crucial for both current practitioners and future engineers aiming to harness the full potential of these remarkable devices. In a world increasingly reliant on efficient fluid dynamics, motorized impellers will undoubtedly play a central role in shaping the future.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025