Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

monoblock pump impeller price

Understanding Monoblock Pump Impeller Prices

When it comes to industrial pumps, the implications of choosing the right components cannot be overstated. Among these components, the impeller plays a crucial role in the functioning and efficiency of monoblock pumps. Not only are they pivotal for fluid dynamics, but they also significantly influence the overall cost of the pump. In this article, we will delve into factors affecting the prices of monoblock pump impellers and what businesses should consider when making purchasing decisions.

What is a Monoblock Pump?

A monoblock pump is a type of centrifugal pump where the motor and pump are assembled into a single unit. This design minimizes space requirements and enhances efficiency. Monoblock pumps are widely used in various applications, including water supply, HVAC systems, and industrial processes, due to their compactness and effectiveness.

The Role of the Impeller

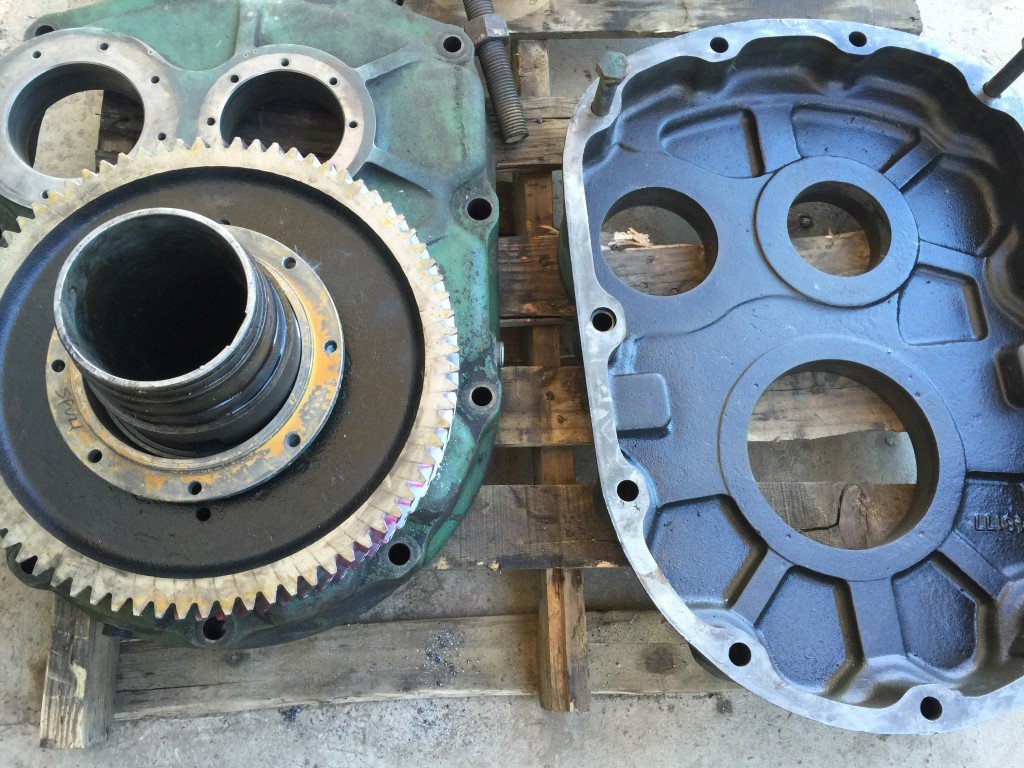

The impeller is the heart of a centrifugal pump. It is a rotating component that imparts energy to the liquid, causing it to flow. The design and material of the impeller can greatly influence the pump's performance, efficiency, and longevity, thus impacting its cost. Various types of impellers can be employed based on the application's requirements, including closed, open, and semi-open designs.

Factors Influencing Impeller Prices

1. Material Composition Impellers can be made of different materials such as stainless steel, cast iron, thermoplastics, or bronze. High-grade materials like stainless steel offer better corrosion resistance and durability, which can come at a higher cost. Businesses must weigh the cost against performance and lifespan when selecting materials.

2. Design Complexity The intricacy of the impeller's design also affects the price. Custom-designed impellers tailored for specific applications tend to be more expensive than standard designs due to the additional engineering involved.

monoblock pump impeller price

3. Manufacturing Process The method used to produce the impeller—whether it’s cast, machined, or 3D printed—also plays a significant role in determining the final price. Advanced manufacturing technologies tend to be more expensive but can offer better precision and shorter lead times.

4. Brand Reputation The reputation of the manufacturer can impact the cost. Well-established brands with a history of reliability and quality often charge more for their products, but investing in such brands may lead to lower costs over time due to reduced maintenance and longer service life.

5. Market Demand Fluctuations in market demand for monoblock pumps and their components can significantly affect pricing. Factors such as seasonal changes and supply chain disruptions can lead to variations in prices. It’s prudent for businesses to keep an eye on market trends to make informed purchasing decisions.

Cost-Effectiveness

While it may be tempting to opt for the least expensive options when purchasing monoblock pump impellers, it is crucial to consider the total cost of ownership. A lower initial price may lead to higher maintenance costs, increased downtime, and a shorter lifespan. Businesses should evaluate the functionality, energy efficiency, and durability of the impeller, which can contribute to long-term savings.

A Comparative Analysis

To get a clearer picture of monoblock pump impeller prices, businesses can perform a comparative analysis of different suppliers in the market. While comparing prices, it’s essential to match products with similar specifications to ensure a fair assessment. In addition, seeking quotes from multiple manufacturers can lead to better deals and help identify the best balance between cost and quality.

Conclusion

Investing in a high-quality monoblock pump impeller is vital for maintaining operational efficiency and reducing long-term costs. By understanding the factors that influence pricing, businesses can make more informed decisions that align with their specific needs. Whether the focus is on material, design, or manufacturer credentials, every aspect plays a vital role in ensuring that the chosen impeller optimally serves its purpose while providing value for money. Ultimately, prioritizing quality and performance will yield significant benefits and prevent costly operational setbacks in the future.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025