Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

metal casting for beginners

A Beginner's Guide to Metal Casting

Metal casting is an ancient technique that transforms molten metal into solid forms, allowing artisans and manufacturers to create a wide range of objects, from simple tools to intricate sculptures. For beginners, the process might seem daunting, but with the right guidance, it can be an exciting and rewarding experience. This article will provide an overview of metal casting, including the basic types, equipment needed, and essential techniques.

Types of Metal Casting

There are several methods of metal casting, each with its unique characteristics

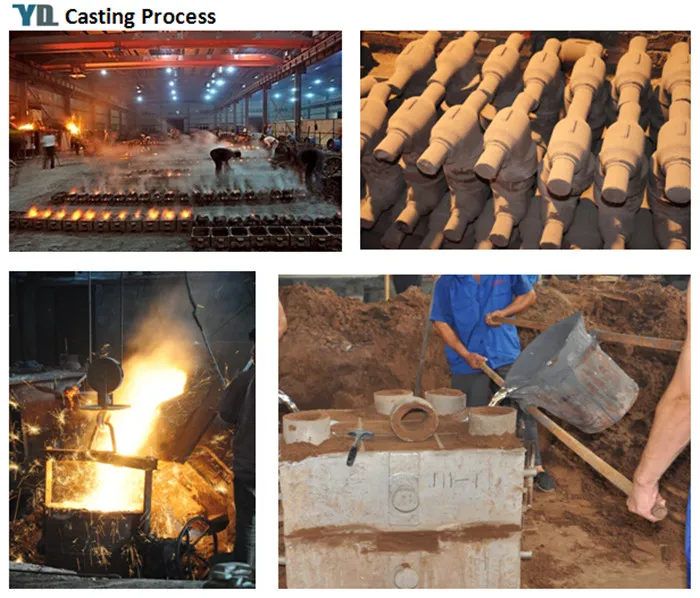

1. Sand Casting This is the most common method for beginners. Sand casting involves creating a mold from a mixture of sand and a binding agent. Once the mold is formed, molten metal is poured into it. This method is relatively inexpensive and allows for intricate designs.

2. Investment Casting Also known as lost-wax casting, this method involves creating a wax model of the object, which is then coated with a ceramic material. The wax is melted away, leaving a hollow mold for the molten metal. This method provides high precision and is often used for jewelry and complex parts.

3. Die Casting In this method, molten metal is injected into a steel mold under high pressure. Die casting is suitable for mass production of small to medium-sized parts with high dimensional accuracy.

Essential Equipment

For beginners, the following equipment is necessary to get started with metal casting

- Melting Furnace A furnace designed to melt the metal you intend to cast. For hobbyists, small propane or electric furnaces are often sufficient.

metal casting for beginners

- Molds You can purchase ready-made molds or create your own using sand or clay

.- Protective Gear Safety is paramount when working with molten metal. Ensure you have protective gloves, goggles, and a welding apron to prevent burns and injuries.

- Crucible This is a container that holds the metal while it’s being melted. Crucibles can be made from various materials, but graphite and ceramic are popular choices due to their heat resistance.

Techniques and Tips

- Preparation is Key Thoroughly prepare your mold before pouring the metal. Any imperfections in the mold can lead to defects in the final product.

- Control the Temperature Each type of metal has a specific melting point. Use a thermocouple or pyrometer to monitor the temperature and ensure the metal is adequately melted.

- Practice Safety Always work in a well-ventilated area and keep flammable materials away from your workspace.

- Start Small As a beginner, start with simple projects, such as small sculptures or simple tools, to build your confidence and skills.

Metal casting can be a fascinating hobby or profession, offering a blend of creativity and craftsmanship. With patience and practice, beginners can unlock the potential of this ancient art form and create beautiful, lasting pieces. Happy casting!

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025