Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Metal Castings | Custom Precision, Fast Lead Times & OEM

Casting Box: Practical Notes From the Metal Shop Floor

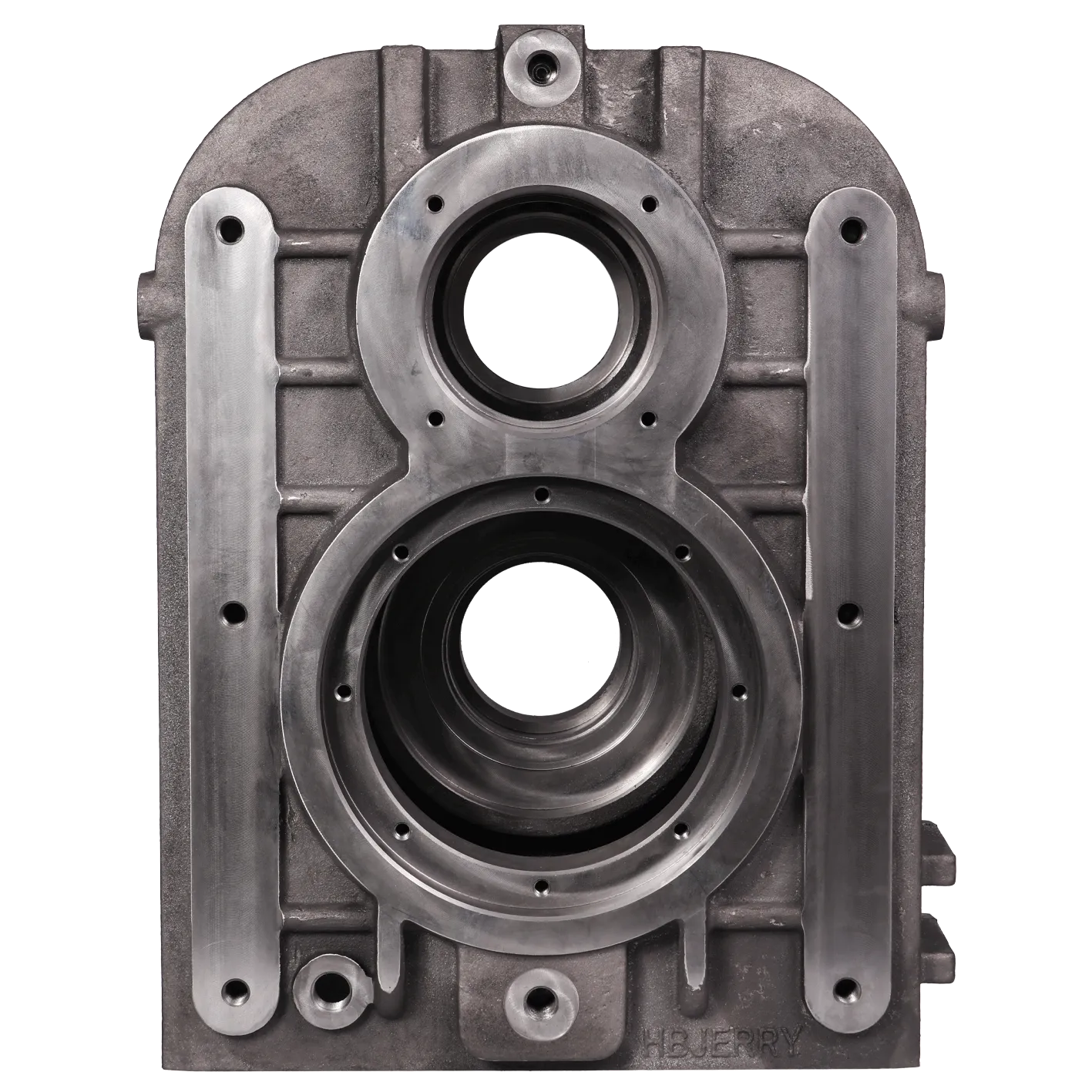

If you spend enough time around foundries, you learn the quiet truth: reliability beats flashy. That’s why buyers looking for metal castings for powertrain housings, pump bodies, and conveyors keep circling back to one unglamorous hero—the Casting Box. Made in Shijiazhuang (No.563 Xinhua Road, Hebei, P.R. China, 050051), this unit leans on proven grades and a disciplined resin-sand process. It’s not hype; it’s throughput.

I’ve toured shops that run three shifts and others that fire once a week—honestly, the best ones obsess over gating design and post-cast QC more than marketing. This one does, which, to be fair, is why the returns are low and the customer notes I’ve seen are mostly boring in the best possible way.

Product Snapshot

Product Name: Casting box. Materials: GG25, ASTM-250S, EN-GJL-250. Process: Resin sand casting + CNC machining. Spec: 100–350 kg per piece. For teams standardizing on metal castings that can take daily abuse in conveyors or crusher housings, this checks the usual boxes.

| Parameter | Specification (≈, real-world use may vary) |

|---|---|

| Material Grades | GG25 / ASTM-250S / EN-GJL-250 (gray iron) |

| Weight Range | 100–350 kg per unit |

| Typical Tensile Strength | ≈ 250 MPa (per EN-GJL-250 baseline) |

| Hardness | HB 190–230 (ISO 6506-1) |

| Dimensional Tolerance | ISO 8062-3 CT8–CT10 typical |

| Surface Finish | Ra ≈ 6.3–12.5 μm as-cast; finer after CNC |

| Service Life | 5–10 years in typical duty; more with proper alignment/lube |

Process Flow (What Actually Happens)

- DFM review: wall thickness, riser/feeder sizing, and stress risers tuned for metal castings.

- Tooling & patterns: CNC patterns; resin-sand molds for thermal stability and definition.

- Melting & Pouring: controlled CE for gray iron; thermal analysis to reduce shrink defects.

- Shakeout & Fettling: gates/risers removed; shot-blast cleaning.

- CNC Machining: datum faces, bores, and tapped holes per drawing.

- Testing: tensile (ASTM E8/E8M), Brinell hardness (ISO 6506-1), dimensional checks (ISO 8062-3), microstructure per EN 1561 guidance.

- Packaging: rust inhibition + foam blocking for export.

Where It’s Used

Conveyor and gearbox housings, pump and valve bodies, crusher frames, mixer bases, and general-purpose enclosures in mining, aggregates, cement, agriculture, and municipal equipment. Many customers say the geometry stability under bolt preload is the quiet advantage—gray iron damps vibration better than steel fabrications, which seems obvious but still surprises new buyers of metal castings.

Vendor Comparison (Abbreviated)

| Vendor | Certifications | Typical Tolerance | Lead Time | Notes |

|---|---|---|---|---|

| YD Castings (Shijiazhuang) | ISO 9001; EN 1561-compliant materials | ISO 8062-3 CT8–CT10 | 4–6 weeks after PO | Strong QC reports; competitive at 100–350 kg |

| Regional Foundry A | ISO 9001 (pending) | CT9–CT11 | 6–8 weeks | Lower tooling cost; slower machining slots |

| Global Group B | ISO 9001/14001 | CT7–CT9 | 8–10 weeks | Premium pricing; broad material menu |

Field Notes, Test Data, and Feedback

- Lot test (recent run): UTS 255–268 MPa; HB 198–212; porosity level ≤ Level 2 on micrographs.

- Flatness on machined face: ≤ 0.15 mm over 600 mm span (sample average; drawing-dependent).

- Customer remark (EU hydraulics OEM): “Zero leaks after 6 months; machining stock was consistent.”

- Another buyer said, to be honest, “we expected more rework,” but they didn’t need it.

Why Choose It

Advantages: vibration damping vs. welded steel, predictable machinability, steady tolerances, and a price point that makes procurement smile. If you need customized metal castings—extra ribs, alternative bore patterns, or a special paint system—tooling tweaks are straightforward, and CNC programs are updated fast.

Mini Case Study

A fertilizer plant replaced welded housings with casting boxes and saw a 12% reduction in bearing failures over nine months. Root cause? Better alignment retention (less weld distortion) and more uniform bolting surfaces. Simple, but effective.

Standards Referenced

ASTM E8/E8M for tensile tests, ISO 6506-1 for Brinell, ISO 8062-3 for casting tolerances, and EN 1561 for gray iron grades (EN-GJL-250). Certifications: ISO 9001 quality management. That’s the backbone for traceable metal castings.

Citations

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025