Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

ls cast manifolds

The Intersection of LS Cast Manifolds and Engine Performance

In the world of automotive performance, enthusiasts constantly seek ways to enhance their engines' efficiency and power output. One critical component that plays a significant role in this pursuit is the intake manifold, specifically the LS cast manifold. The LS series of engines, originally developed by General Motors, are renowned for their robust designs and extensive aftermarket support, making them a popular choice for performance builds.

Understanding LS Cast Manifolds

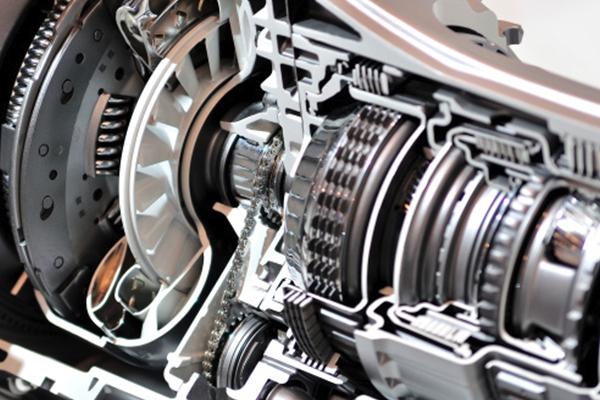

At its core, an LS cast manifold serves as the bridge between the engine’s air intake and its combustion chambers. Its primary function is to distribute the air-fuel mixture uniformly across all cylinders to optimize combustion efficiency. LS cast manifolds are typically made from aluminum, allowing for a lightweight yet durable structure capable of withstanding high temperatures and pressures.

The design and construction of these manifolds can significantly impact an engine’s performance. The cast aluminum construction provides excellent thermal conductivity, which helps maintain the engine’s optimal operating temperature. Additionally, cast manifolds can be engineered with varying runner lengths and cross-sectional areas, allowing builders to tailor performance characteristics based on specific applications, whether for drag racing or street performance.

Performance Considerations

When choosing LS cast manifolds, several factors need to be taken into account. The manifold's design affects not only the power output but also the torque curve and throttle response. Generally, a shorter runner design can improve high-end power, making it favorable for racing applications. Conversely, a longer runner can enhance low-end torque, which is beneficial for daily driving situations.

ls cast manifolds

Moreover, the smoothness of the manifold’s interior surfaces plays a critical role in airflow dynamics. A more polished interior reduces turbulence and resistance, promoting a more efficient flow of the air-fuel mixture into the cylinders. This, in turn, leads to improved combustion efficiency and, ultimately, increased horsepower and torque.

Aftermarket Options and Modifications

The LS cast manifold scene is rife with aftermarket options, catering to various performance needs and budgets. Brands such as Edelbrock, Holley, and MSD offer a plethora of choices, from high-performance street manifolds to dedicated race setups. Many enthusiasts prefer to customize their manifolds further by porting and polishing the runners for even greater airflow benefits.

Another popular modification is the installation of larger throttle bodies in conjunction with an LS cast manifold. A bigger throttle body can improve the amount of air entering the engine, enhancing performance, especially when paired with other modifications like aftermarket camshafts and headers.

Conclusion

In conclusion, LS cast manifolds are a cornerstone of engine performance modification for LS enthusiasts. Their role in optimizing air intake directly influences an engine's efficiency, power output, and overall performance characteristics. With various designs available in the aftermarket, car builders can tailor their setups to fit their specific performance goals. Whether you're chasing horsepower on the racetrack or simply want a more responsive engine for daily driving, investing in a quality LS cast manifold can yield significant benefits and help unlock the full potential of your engine. As automotive technology continues to advance, the evolution of LS cast manifolds will undoubtedly play a vital role in shaping the future of performance engines.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025