Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Optimizing Performance of Impeller Turbines for Enhanced Energy Efficiency and Reliability

The Impeller Turbine A Technological Marvel in Fluid Mechanics

In the realm of fluid dynamics, the impeller turbine stands as a crucial innovation, significantly enhancing the efficiency of various mechanical applications. This advanced rotor-driven device is widely used in industries ranging from hydroelectric power generation to marine propulsion and wastewater treatment. Understanding how impeller turbines function, their design considerations, and applications provides valuable insights into their importance in modern engineering.

The Basics of Impeller Turbines

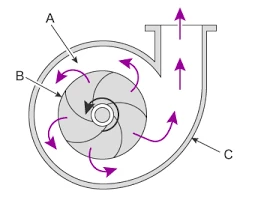

At its core, an impeller turbine consists of a rotating disk or wheel equipped with blades that impart kinetic energy to a fluid. When fluid enters the impeller, it interacts with the blades, which convert the fluid’s pressure energy into velocity energy, resulting in an increased flow rate at the turbine's outlet. This transformation is governed by principles of fluid dynamics and thermodynamics, wherein the design of the blades directly affects the turbine's performance.

The geometry of the impeller is paramount. Various blade shapes, angles, and arrangements can optimize the turbine for specific applications, improving efficiency while minimizing drag and turbulence. Typically, impellers are classified based on their orientation (radial, axial, or mixed flow) and the specific fluid dynamics they employ. The choice of configuration often depends on the desired performance parameters, including flow rate, pressure head, and rotational speed.

Efficiency and Performance

The performance of impeller turbines can be quantified through several key metrics, including the hydraulic efficiency, which is defined as the ratio of the turbine's hydraulic power to the input power. For an impeller turbine, achieving high efficiency is essential; this is typically accomplished through careful design, material selection, and operational parameters. Advanced computational fluid dynamics (CFD) simulations are now commonly employed in the design phase to predict flow patterns and optimize blade shapes before physical prototypes are constructed.

Another vital aspect of performance is cavitation—a phenomenon that occurs when the local pressure drops below the vapor pressure of the fluid, leading to bubble formation that can cause significant damage to the turbine. Mitigating cavitation is critical, and designers must account for inlet velocities, blade designs, and operational conditions to minimize this risk.

impeller turbine

Applications of Impeller Turbines

Impeller turbines have a broad spectrum of applications. In the hydroelectric industry, they are utilized in turbine generators to convert the potential energy of water into mechanical energy and, subsequently, electrical energy. These turbines are designed to handle varying flow conditions and can operate efficiently across a wide range of water levels.

In the field of marine propulsion, impellers are integral to the operation of pump-jet systems and water jets, which provide thrust for boats and ships. Their high efficiency at different speeds makes them particularly suitable for high-performance vessels, including military ships and fast ferries.

Another significant application is in the wastewater treatment industry, where impeller turbines are used in aeration processes. These turbines help to mix air with wastewater, promoting the growth of aerobic bacteria that break down organic matter. This application illustrates the versatility of impeller designs, which can be optimized for both mixing and pumping functions.

Future Trends and Innovations

As technology progresses, the future of impeller turbines is likely to witness innovations driven by advancements in materials science and simulation technologies. Lightweight materials can improve the durability and performance of turbine components, while enhanced computational models can lead to better design optimization. Additionally, the integration of smart technologies may allow for real-time monitoring and adjustments to turbine operations, further increasing efficiency and reliability.

In conclusion, the impeller turbine represents a fascinating interplay of design and engineering principles. Its widespread usage across various industries highlights its importance as a critical component in modern fluid dynamics applications. As research continues to advance, the potential for improvements in efficiency and performance makes the future of impeller turbines a promising field.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025