Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

High-Quality Pump Connector Castings - Hebei Yuanda Trade Co., Ltd.

Connectors are critical components in pump equipment, ensuring seamless integration between various parts and piping systems. These castings, typically made from durable materials like cast iron, stainless steel, or aluminum alloys, play a vital role in maintaining the performance, stability, and longevity of pumping systems. This article delves into the technical specifications, advantages, and applications of high-quality pump connector castings, while also highlighting the expertise of Hebei Yuanda Trade Co., Ltd., a leading manufacturer in this field.

Understanding the Role of Pump Connector Castings

Connector castings serve as the backbone of pump systems, facilitating the connection between different components such as impellers, valves, and pipes. Their design and material selection are crucial to the overall efficiency and reliability of the equipment. For instance, impeller systems rely on precision-engineered connectors to maintain optimal flow and pressure. The right connectors not only ensure proper operation but also minimize the risk of leaks, wear, and structural failure, which can lead to costly downtime and maintenance.

Materials like GG25-Cast iron are commonly used due to their strength and resistance to corrosion. However, the choice of material must align with the specific demands of the application, including factors such as temperature, pressure, and exposure to chemicals. Cap ends, for example, require high-dimensional accuracy to ensure airtight seals, while water pump impeller components need to withstand continuous operation under varying conditions.

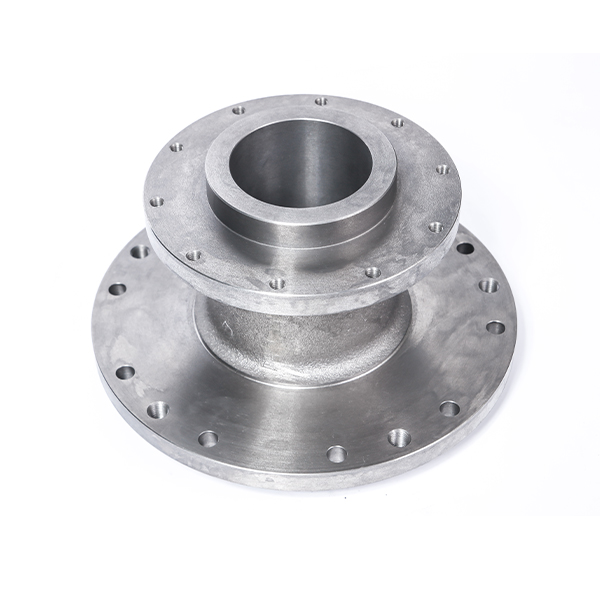

High-precision connector castings are essential for maintaining the integrity of pump systems. The image above showcases the intricate design and quality of these components.

Key Advantages of Quality Connector Castings

Investing in high-quality connector castings offers numerous benefits, including enhanced performance, reduced maintenance costs, and improved safety. One of the primary advantages is corrosion resistance, which is critical in environments where pumps are exposed to harsh chemicals or moisture. Stainless steel and aluminum alloys are particularly effective in such scenarios, as they resist oxidation and maintain structural integrity over time.

Another significant advantage is wear resistance. Pumps operating under high pressure or with abrasive materials require connectors that can endure prolonged use without degrading. Advanced casting techniques, such as resin sand casting, ensure that the final product has minimal surface defects, reducing the need for post-processing and extending the lifespan of the equipment.

Furthermore, the dimensional accuracy of connector castings directly impacts the sealing performance of pumps. According to the National Institute of Standards and Technology (NIST), precision in manufacturing is essential for ensuring the reliability of industrial components (NIST, 2025). By adhering to strict tolerances, manufacturers like Hebei Yuanda Trade Co., Ltd. guarantee that their products meet the highest standards of quality and functionality.

Advanced casting techniques ensure that connectors meet stringent dimensional requirements, as seen in this image of a precision-engineered pumpe impeller.

Technical Specifications of Pump Connector Castings

| Product Name | Weight | Material | Casting Process |

|---|---|---|---|

| Connectors | 5-50kg | GG25-Cast Iron | Resin Sand Casting |

The specifications above highlight the versatility and durability of these connector castings. The weight range of 5-50kg makes them suitable for a wide range of applications, from small-scale industrial systems to large commercial pumps. The use of resin sand casting ensures that the final product has a smooth surface with no sand holes or air pockets, reducing the need for additional machining and improving production efficiency.

Cap ends, a critical component in pump systems, are manufactured to exacting standards to ensure optimal performance and durability.

Applications of Pump Connector Castings

Pump connector castings are indispensable in various industries, including water treatment, oil and gas, and chemical processing. In water treatment facilities, these connectors are used to link pumps with filtration systems, ensuring the efficient transport of liquids. Similarly, in the oil and gas sector, they play a vital role in maintaining the integrity of pipelines and storage tanks under high-pressure conditions.

In the water pump impeller industry, connectors are essential for maintaining the alignment and stability of the impeller assembly. Any deviation in the casting process can lead to imbalances, reducing the pump's efficiency and increasing energy consumption. By leveraging advanced manufacturing techniques, Hebei Yuanda Trade Co., Ltd. ensures that their products meet the exacting demands of these applications.

Moreover, the impeller on pump systems benefit from connectors that can withstand continuous operation without compromising performance. This is particularly important in industrial settings where pumps are required to operate 24/7, making reliability a top priority.

The smooth surface and high accuracy of these castings contribute to the efficiency and longevity of water pump impeller systems.

About Hebei Yuanda Trade Co., Ltd.

As a leading manufacturer of industrial castings, Hebei Yuanda Trade Co., Ltd. has established itself as a trusted name in the production of high-quality pump connector castings. With a focus on precision engineering and customer satisfaction, the company has consistently delivered products that meet the highest standards of quality and performance.

Hebei Yuanda Trade Co., Ltd. employs state-of-the-art casting technologies, including resin sand casting, to produce connectors that are both durable and cost-effective. Their commitment to innovation is reflected in their ability to adapt to the evolving needs of the industry, offering customized solutions for a wide range of applications.

The company's dedication to excellence is further evidenced by its rigorous quality control processes. Each product undergoes thorough inspection to ensure dimensional accuracy, surface finish, and material integrity. This attention to detail has earned Hebei Yuanda Trade Co., Ltd. a reputation for reliability and consistency in the global market.

Conclusion

In conclusion, high-quality pump connector castings are essential for the efficient and reliable operation of industrial pumping systems. Their design, materials, and manufacturing processes must meet stringent standards to ensure optimal performance and longevity. By partnering with Hebei Yuanda Trade Co., Ltd., businesses can access premium connectors that meet the demands of even the most challenging applications.

For more information about connector castings and the services offered by Hebei Yuanda Trade Co., Ltd., visit their official website. With a commitment to innovation, quality, and customer satisfaction, the company continues to set the benchmark for excellence in the industrial casting industry.

References

NIST. (2025). National Institute of Standards and Technology. Retrieved from https://www.nist.gov/

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025