Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

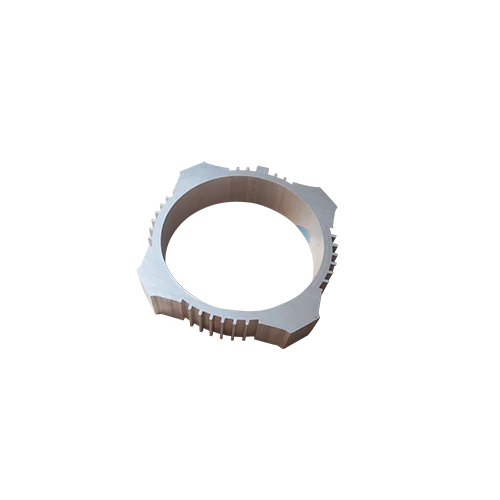

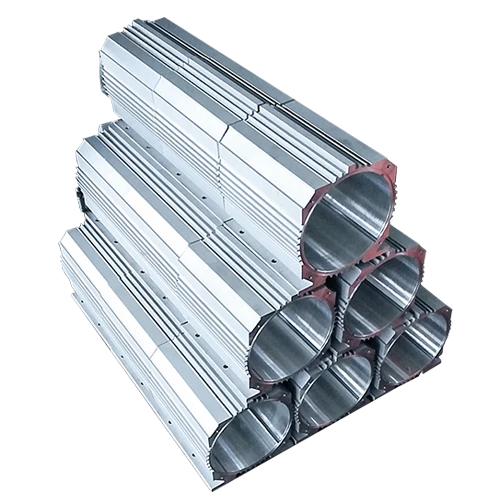

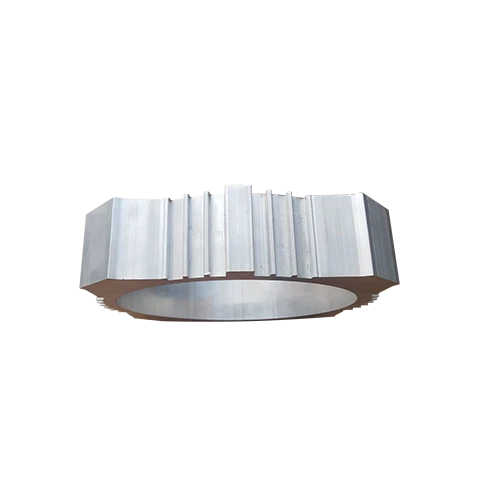

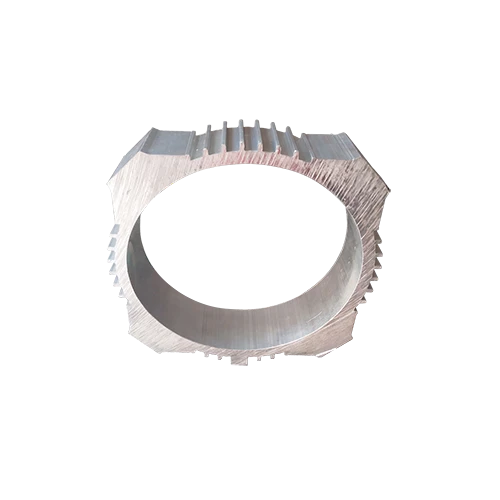

High-Quality Motor Shells | Durable Motor Protection

The motor shell serves as the critical protective housing for electric motors across countless industries. As the global electrification movement accelerates, demand for precision-engineered motor shells has increased by 35% over the past five years according to IEA reports. At Hebei Yuanda Trade Co., Ltd., we specialize in manufacturing premium aluminum motor shells designed to meet the exacting standards of modern motor applications. Our motor shells protect vital components while facilitating optimal thermal management in challenging operating environments.

Hebei Yuanda Premium Motor Shell

Introducing our flagship product designed for superior performance:

Industrial Grade Motor Shell

- ✅ Material: 6063, 6061 Aluminum Alloys

- ✅ Process: Extruded and Drawn Profile

- ✅ Specification: Diameter 20mm-400mm

- ✅ Application: Industrial Motors, EV Components, Robotics

- ✅ Surface Treatment Options: Anodized, Powder Coated, Sandblasted

Motor Shell Technical Specifications

| Parameter | 6061 Aluminum | 6063 Aluminum | Industry Standard |

|---|---|---|---|

| Tensile Strength | 290 MPa | 240 MPa | ANSI B46.1 |

| Thermal Conductivity | 170 W/m·K | 200 W/m·K | ASTM E1461 |

| Corrosion Resistance | Excellent | Superior | ISO 9227 |

| Operating Temperature | -20°C to 120°C | -30°C to 150°C | IEC 60085 |

Motor Shell Application Areas

Modern motor shells serve critical functions in numerous industries:

Advanced Motor Shell Technology Trends

Industry innovations are reshaping motor shell design according to recent IEEE studies:

Material Science Advancements

Aluminum composites now achieve 10-15% better thermal dissipation than conventional alloys while reducing component weight by 12%.

Manufacturing Evolution

New 5-axis CNC machining techniques enable complex geometries meeting ISO 2768 tolerance levels.

Technical Questions About Motor Shells

What wall thickness is recommended for high-torque applications?

For industrial motors requiring robust solutions, we recommend a minimum 4-6mm thickness on 6061 aluminum motor shells subjected to >100 N·m torque loads.

How does material selection affect thermal performance?

6063 aluminum provides 15% better thermal dissipation than 6061 - critical for applications requiring compact motor shells with limited airflow.

What certifications do your motor shells meet?

Our products comply with RoHS, REACH, and ISO 9001 manufacturing standards for international markets.

What surface treatments prevent corrosion?

Type III anodizing provides maximum salt spray resistance (1,500+ hours per ASTM B117 testing standards).

How are vibration tolerances calculated?

Finite Element Analysis (FEA) simulations predict harmonic responses based on IEC 60034-14 classification.

What tolerance ranges do you achieve?

Standard machining maintains ±0.05mm tolerances across diameters per ISO 2768 standards.

Can you integrate cooling channels?

Custom motor shells can incorporate internal water-glycol passageways for motors exceeding 15 kW capacities.

Industry Research References

Technical Publications:

- Journal of Materials Engineering: "Thermal Analysis of Aluminum Alloys in Electric Motor Enclosures" Read Study

- International Electric Machines Symposium: "Advances in Motor Shell Manufacturing" Research Paper

- Advanced Industrial Manufacturing Review: "Tolerance Standards for Electric Motor Components" Technical Report

Ready to Discuss Your Motor Shell Requirements?

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025