Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

High-Quality Connector Castings | Hebei Yuanda Trade Co., Ltd.|Precision Engineering&Industrial Solutions

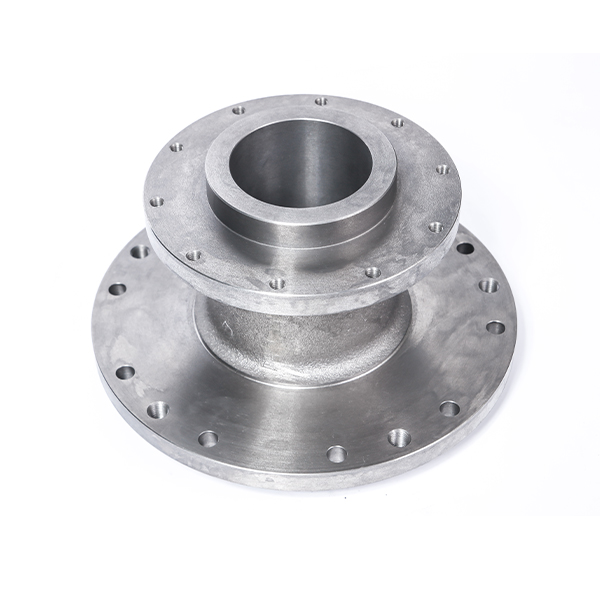

In the realm of industrial machinery, connector castings play a pivotal role in ensuring the seamless operation of pump equipment. These critical components are designed to connect various parts or piping systems, and their quality directly impacts the efficiency, reliability, and longevity of the entire system. This article delves into the features, advantages, technical specifications, and applications of connector castings, while also exploring the expertise of Hebei Yuanda Trade Co., Ltd., a leading manufacturer in this field.

Understanding the Role of Connector Castings

Connector castings are essential components in pump equipment, serving as the bridge between different mechanical parts. Their primary function is to ensure a secure and stable connection, preventing leaks and mechanical failures. These castings are typically manufactured from high-quality metal materials such as cast iron, stainless steel, or aluminum alloys, each chosen for its unique properties to meet specific operational demands.

The design and material selection of connector castings are critical to the performance and stability of pump equipment. High-quality connector castings not only enhance the operational efficiency of the system but also reduce the risk of leakage or damage. When selecting connector castings, factors such as corrosion resistance, wear resistance, and the ability to withstand pressure must be carefully evaluated. These considerations ensure that the connector castings can perform optimally under demanding conditions.

Key Features of High-Quality Connector Castings

Connector castings are engineered to meet stringent performance requirements. One of their standout features is shape accuracy, which ensures that the final product aligns precisely with design specifications. This is achieved through the use of fine molds and advanced equipment, which minimize dimensional errors. For pump equipment, shape accuracy is crucial, as it directly affects the sealing performance of the system.

Another critical feature is dimensional accuracy, which refers to the degree of precision in the final product's measurements. This is a key indicator of casting quality, especially for pump parts that must meet strict dimensional requirements for proper installation and performance. Additionally, surface quality is vital, as a smooth, defect-free surface reduces the need for subsequent machining and grinding processes, thereby improving production efficiency. High-quality connector castings also contribute to the efficiency and service life of pump equipment, while reducing the failure rate.

Technical Specifications of Connector Castings

| Parameter | Specification |

|---|---|

| Material | GG25-Cast Iron, Stainless Steel, Aluminum Alloys |

| Casting Process | Resin Sand Casting |

| Weight Range | 5-50 kg |

| Shape Accuracy | High precision, minimal dimensional errors |

| Surface Quality | Smooth, free from sand holes and air holes |

| Production Efficiency | Advanced technology for mass production |

Advantages of Quality Connector Castings

The advantages of quality connector castings extend beyond their performance and durability. These components are designed to enhance the efficiency and reliability of pump equipment. By minimizing leakage and damage, they reduce maintenance costs and downtime, which is crucial for industrial operations. Additionally, connector castings manufactured with corrosion resistance and wear resistance can withstand harsh environments, making them suitable for applications in industries such as water treatment, chemical processing, and oil and gas.

Moreover, the advanced production technology used in manufacturing connector castings ensures mass production without compromising product quality. This not only reduces energy consumption and labor costs but also improves production efficiency. For manufacturers, this translates to a competitive edge in the market, as they can deliver high-quality connector castings at a lower cost.

Applications of Connector Castings in Industrial Settings

Connector castings are widely used in various industrial applications, particularly in systems that require fluid transfer. In water treatment facilities, these components ensure the sealing and pressure resistance of pump equipment, which is critical for maintaining water quality and system efficiency. Similarly, in chemical processing plants, connector castings are used to connect piping systems that handle corrosive substances, ensuring safety and compliance with industry standards.

In the oil and gas sector, connector castings are essential for pump equipment used in refining and distribution processes. Their pressure resistance and corrosion resistance make them ideal for handling high-temperature and high-pressure environments. Additionally, in manufacturing and construction industries, connector castings are used to connect hydraulic systems and pneumatic equipment, ensuring reliability and safety in complex machinery.

About Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. is a trusted manufacturer and supplier of connector castings and other industrial castings. With years of experience in the industry, the company has established itself as a leader in providing high-quality metal castings that meet the rigorous demands of modern manufacturing. Their commitment to innovation and quality control ensures that every connector casting produced is reliable, durable, and designed to deliver optimal performance.

Hebei Yuanda Trade Co., Ltd. specializes in resin sand casting for cast iron and other metal materials, ensuring shape accuracy and dimensional precision. The company's advanced production technology enables mass production while maintaining product quality. This dedication to excellence has earned them a strong reputation among clients worldwide, who rely on their connector castings for critical industrial applications.

Authoritative Citations and References

The importance of connector castings in industrial systems is supported by research and standards from reputable organizations. According to the National Institute of Standards and Technology (NIST), precision in casting processes is essential for ensuring the performance and reliability of machinery. NIST's work in metrology and manufacturing standards underscores the need for dimensional accuracy and material integrity in industrial components.

As noted by NIST, "The precision of casting processes directly impacts the efficiency and safety of industrial systems. High-quality castings are critical for maintaining operational reliability and longevity in mechanical equipment." (NIST, 2023). This aligns with the principles of Hebei Yuanda Trade Co., Ltd., which prioritizes precision and quality control in all its products.

For further information on NIST's standards and research, visit their official website: https://www.nist.gov/.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025