Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

High-Performance Connectors-Pump Equipment|Precision Engineering&Durable Materials

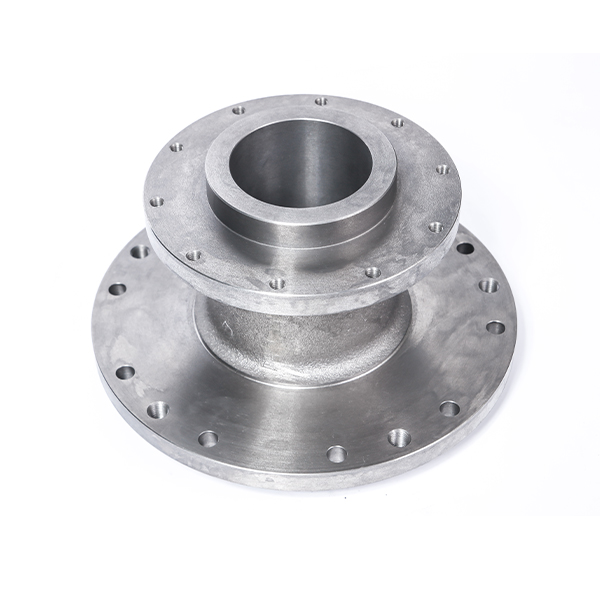

Connectors play a critical role in the seamless operation of pump equipment, ensuring reliable connections between components and pipes. These essential parts are typically crafted from durable materials like cast iron, stainless steel, or aluminum alloys, chosen for their ability to withstand harsh environments. This article explores the features, advantages, technical specifications, and application scenarios of high-quality connector castings, while also highlighting the expertise of Hebei Yuanda Trade Co., Ltd., a leading supplier of industrial casting solutions.

Understanding Connector Castings: Key Features and Benefits

Connector castings are designed to maintain the structural integrity and efficiency of pump systems. Their high shape accuracy and dimensional precision are critical for ensuring proper sealing and performance. Advanced casting techniques, such as resin sand casting, enable manufacturers to produce parts with minimal defects, such as sand holes or air bubbles. These improvements not only enhance the surface quality of the castings but also reduce the need for post-processing, lowering production costs and improving overall efficiency.

One of the standout features of modern connector castings is their corrosion resistance and wear resistance. These properties are achieved through careful material selection and specialized surface treatments. For instance, cast iron connectors are often used in applications where durability is paramount, while stainless steel variants are preferred in environments with high exposure to moisture or chemicals. The ability to withstand pressure and maintain structural integrity under demanding conditions makes these castings indispensable in industries such as water treatment, oil and gas, and industrial manufacturing.

Technical Specifications: Precision Meets Performance

| Parameter | Details |

|---|---|

| Product Name | Connectors |

| Weight | 5-50kg |

| Material | GG25-Cast Iron |

| Casting Process | Resin Sand Casting |

| Surface Quality | Smooth, defect-free |

| Shape Accuracy | High precision |

| Dimensional Accuracy | Minimal size error |

The technical specifications of these connectors are engineered to meet the rigorous demands of industrial applications. For example, the resin sand casting process ensures that the final product adheres to strict dimensional tolerances, which is vital for compatibility with other pump components. Additionally, the smooth surface finish reduces friction and wear, extending the lifespan of the pump system. These attributes are backed by industry standards, as highlighted by the National Institute of Standards and Technology (NIST), which emphasizes the importance of precision in manufacturing processes (NIST, 2023).

Applications in Industrial and Commercial Settings

Connector castings are widely used across various sectors, including water treatment plants, chemical processing facilities, and power generation systems. In water treatment, for instance, their corrosion resistance ensures long-term reliability in environments with high humidity and chemical exposure. Similarly, in the oil and gas industry, the ability to withstand extreme pressures and temperatures makes these connectors a preferred choice for critical applications.

Another key application is in industrial pump systems, where connectors facilitate the transfer of fluids and gases. The dimensional accuracy of these parts ensures a secure fit, minimizing the risk of leaks or mechanical failure. For example, in HVAC systems, connectors made from aluminum alloys provide lightweight yet durable solutions, enhancing energy efficiency and reducing maintenance costs.

The Role of Hebei Yuanda Trade Co., Ltd. in Manufacturing Excellence

As a trusted supplier of casting solutions, Hebei Yuanda Trade Co., Ltd. has established itself as a leader in the production of high-quality connector castings. The company’s commitment to innovation and precision is evident in its advanced manufacturing processes, which include state-of-the-art casting technologies and rigorous quality control measures. By leveraging resin sand casting, Hebei Yuanda ensures that its products meet the highest standards of performance and reliability.

The company’s expertise extends beyond production, as it also provides tailored solutions to meet the specific needs of its clients. Whether it’s customizing connectors for unique applications or optimizing existing designs for improved efficiency, Hebei Yuanda’s team of engineers and technicians works closely with customers to deliver exceptional results. This customer-centric approach has earned the company a strong reputation in both domestic and international markets.

Why Choose High-Quality Connector Castings?

Investing in high-quality connector castings offers numerous benefits that translate into long-term cost savings and operational efficiency. For example, the smooth surface finish of these parts reduces the need for additional machining, lowering production costs. Additionally, their corrosion resistance and wear resistance ensure that pump systems operate at peak performance for extended periods, reducing downtime and maintenance expenses.

Moreover, the dimensional accuracy of these connectors minimizes the risk of installation errors, which can lead to costly repairs or system failures. This level of precision is particularly important in industries where even minor deviations can have significant consequences. By choosing connectors from Hebei Yuanda Trade Co., Ltd., customers gain access to products that are engineered to deliver consistent, reliable performance in the most demanding environments.

Conclusion: The Future of Pump Equipment Connectivity

As industrial and commercial demands continue to evolve, the importance of reliable connector castings cannot be overstated. With their combination of high shape accuracy, dimensional precision, and superior material properties, these components are essential for ensuring the efficiency and longevity of pump systems. Hebei Yuanda Trade Co., Ltd. remains at the forefront of this industry, delivering innovative solutions that meet the needs of modern manufacturing.

For businesses seeking to optimize their operations, partnering with a reputable supplier like Hebei Yuanda Trade Co., Ltd. is a strategic choice. By prioritizing quality, precision, and customer satisfaction, the company continues to set the standard for connector castings in the global market.

References

National Institute of Standards and Technology (NIST). (2023). Standards for Manufacturing Precision. Retrieved from https://www.nist.gov.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025