Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

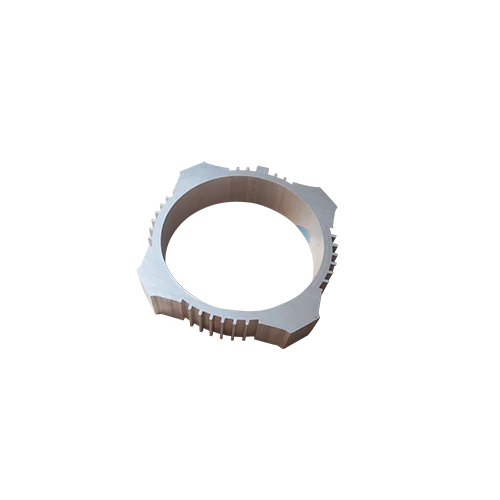

gravity casting aluminium

Gravity Casting of Aluminium An Overview

Gravity casting, also known as gravitation molding, is a widely utilized casting process in the manufacturing industry, particularly for non-ferrous metals such as aluminum. This method employs gravitational force to fill the mold with molten metal, making it a reliable and efficient technique for producing complex shapes and high-quality components. In this article, we will explore the fundamentals of gravity casting aluminum, its advantages, applications, and key considerations.

Gravity Casting of Aluminium An Overview

One of the primary advantages of gravity casting aluminum is its ability to produce parts with excellent dimensional accuracy and surface finish. This is particularly important in industries where precision is critical, such as aerospace and automotive sectors. Additionally, the process is efficient and cost-effective, especially for large-scale production runs. The use of aluminum, known for its lightweight and high strength-to-weight ratio, makes it a favorable choice for manufacturers seeking to minimize weight without compromising structural integrity.

gravity casting aluminium

Another benefit of gravity casting is the versatility it offers. This method can be employed to create a wide range of aluminum components, from intricate designs to larger pieces. Industries such as consumer electronics, machinery, and sporting goods take advantage of gravity casting to manufacture everything from housings and casings to structural supports. Its adaptability to various geometries and sizes makes it a preferred choice for many engineering applications.

However, there are some considerations to keep in mind when opting for gravity casting aluminum. The process may not be suitable for all aluminum alloys, as some may require specific casting techniques to achieve desired properties. Additionally, the complexity of the mold design can impact production costs and lead times. Careful planning and design are essential to optimize both the manufacturing process and the quality of the finished product.

In conclusion, gravity casting of aluminum represents a fundamental technique in the field of metalworking, characterized by its reliability, cost-effectiveness, and ability to produce high-quality components. With the continued advancements in casting technologies and materials, the relevance of gravity casting is likely to persist, providing manufacturers with the tools to meet evolving demands across various industries. As the market for lightweight and high-performance materials expands, gravity casting remains an integral process for producing aluminum components that meet the exacting standards of modern engineering.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025