Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Heavy Duty GI Pipe End Caps for Secure and Durable Pipe Sealing Solutions

Understanding GI Pipe End Caps Essential Components in Piping Systems

Galvanized Iron (GI) pipe end caps are crucial components in various plumbing and industrial applications. Their primary function is to seal the end of a pipe, providing a secure and leak-proof closure. This article explores the significance, types, installation, and benefits of GI pipe end caps, particularly in plumbing systems.

What Are GI Pipe End Caps?

GI pipe end caps are fittings made from galvanized iron, a type of steel coated with zinc to prevent rust and corrosion. These end caps come in various sizes and shapes to accommodate different pipe diameters and are designed to fit snugly onto the ends of pipes. The galvanization process enhances the durability of these caps, making them suitable for both indoor and outdoor applications where moisture and environmental factors can pose a risk to unprotected metal.

Significance of GI Pipe End Caps

One of the primary purposes of GI pipe end caps is to provide a leak-proof seal to the ends of pipes. This is particularly important in systems where liquids or gases are transported, as leaks can lead to significant issues, including loss of material and safety hazards. By effectively sealing the pipe ends, end caps help maintain the integrity of the piping system.

Additionally, GI pipe end caps play a role in protecting the internal surfaces of the pipe from dust, debris, and moisture, which can lead to corrosion or blockages over time. They are also essential for preventing any accidental flow of substances during maintenance activities or while the system is inactive.

Types of GI Pipe End Caps

GI pipe end caps come in several types based on their design and application

1. Threaded End Caps These caps have internal threads and can be screwed onto pipes with external threads. This type ensures a tight fit and is used in high-pressure applications. 2. Welded End Caps Designed for permanent application, these caps are welded onto the ends of pipes. They are commonly used in industrial settings where the integrity of the seal is crucial.

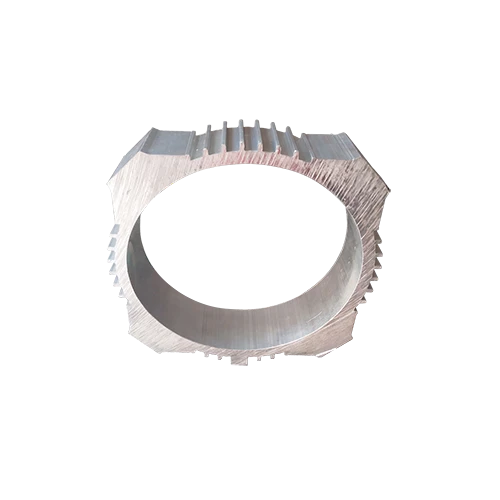

gi pipe end cap

3. Slip-On End Caps These caps simply slide over the pipe ends and may require additional fastening methods, such as adhesives or clamps, for a secure fit. They are easier to install compared to threaded or welded caps.

Installation of GI Pipe End Caps

Installing GI pipe end caps is a straightforward process but requires attention to detail to ensure a proper seal. For threaded end caps, the pipe threads must be clean and free of debris before applying thread sealant or Teflon tape to enhance sealing and prevent leaks. The end cap is then screwed onto the pipe until tight.

For welded end caps, the process involves aligning the cap on the pipe end and using a welding machine to create a strong and permanent bond. It is crucial to ensure that the weld is uniform and covers the entire circumference of the joint.

Benefits of Using GI Pipe End Caps

1. Corrosion Resistance Thanks to their galvanized coating, GI pipe end caps provide excellent resistance to rust and corrosion, ensuring longevity in various environments.

2. Leak Prevention By sealing the ends of pipes, they significantly reduce the risk of leaks, contributing to system efficiency and safety.

3. Versatility GI pipe end caps can be used in a range of applications, from residential plumbing to industrial piping systems, making them highly versatile.

4. Cost-Effectiveness Given their durability and long lifespan, GI pipe end caps are a cost-effective choice for maintaining piping systems, as they require less frequent replacement compared to non-galvanized options.

In conclusion, GI pipe end caps are indispensable in ensuring the efficient and safe operation of piping systems. Their ability to provide corrosion resistance, leak prevention, and versatility make them vital components in both residential and industrial contexts.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025